Catalog excerpts

Cable Pusher BKS 800 Have you ever been faced with the task of pulling cable along meandering courses, through street under crossings or in narrow ducts? If so, you will know how soon the stress limit of the cable being pulled is reached and how soon you will have to fit a connection piece. In order to avoid premature cable cutting and fitting of connection pieces, it is advisable to use a Bagela Cable Pusher in front of a bend, which will reduce cable stress and allow longer cable lengths to be pulled. Each use of the Cable Pusher BKS 800 will save the cost of fitting one connection piece. No extra time will be squandered for - cutting the cable, - moving the cable drum. - excavating a connection pit, - barring of the connection pit. - refilling the connection pit. Function: The cable passes over two pairs of tapered pulleys, which are driven by electric or hydraulic motor. Two counter pulleys press the cable into the grooves of the two driving pulleys, thus ensuring adequate friction. For effective power transmission the tapered driving pulleys are consisting of a special, highly elastic, tough and wear-resistant rubber material with a high coefficient of friction. The gap between the tapered pulleys can be varied, so that cable and tubes of 30 to 180 mm in diameter and three single lead 20 kV cables in one strand can be pushed. After the cable has been laid in place, the press-on unit can be removed and the cable taken out and put aside. As the machine is extremely low (340 mm), there will be no unwanted bends in the cable after pushing. Specifications are subject without notice. Output details are depending on use conditions.

Open the catalog to page 1

Owing to its compact design the cable pusher may be used in any cable trench or pit. The cable pusher is driven by an electric motor. By means of appropriate power distributors, several cable pushers may be operated in parallel. Upon request, the cable pusher will be supplied with hydraulic motor to be connected to a hydraulic power pack or the hydraulic system of a mini-excavator. Cable Pusher BKS 800 used for laying 110 kV cable in an industrial site. Where the passage is free, cable pulling may be continued by means of a cable-pulling winch, which draws the cable direct on to the cable...

Open the catalog to page 2All Bagela Baumaschinen GmbH & Co. KG catalogs and technical brochures

-

Asphalt-Recycler

6 Pages

-

Pipe-renewal

14 Pages

-

Blow-In Systems

20 Pages

-

Trailers

24 Pages

-

Winches

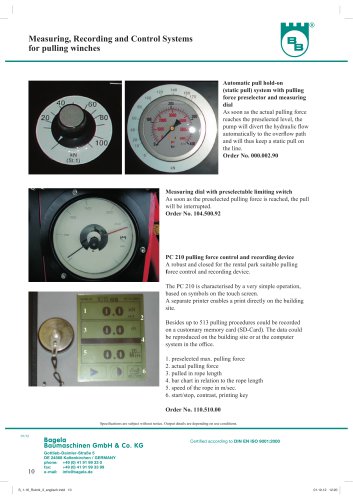

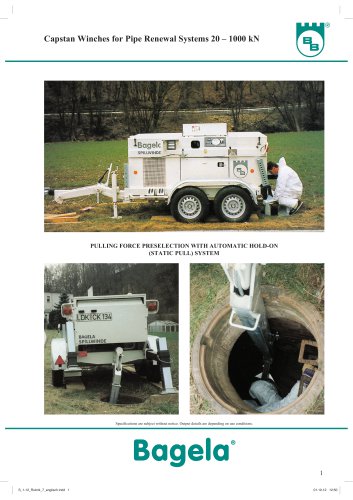

18 Pages

-

RBH40-63

1 Pages

-

Pipe Laying

2 Pages

-

Deflection booms and rollers

2 Pages

-

Duct brushes

1 Pages

-

Pipe Cleaning

2 Pages

-

Accessories

1 Pages

-

Calibration accessories

4 Pages

-

Cable Pulling grips

4 Pages

-

Length measuring devices

2 Pages

-

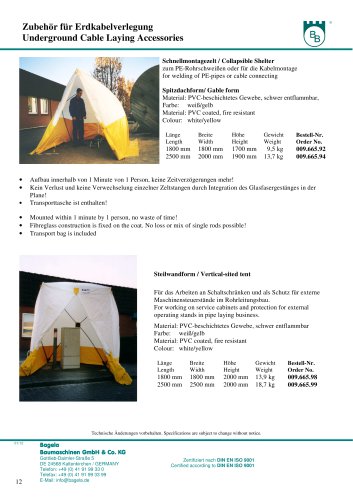

Tents and screens

2 Pages

-

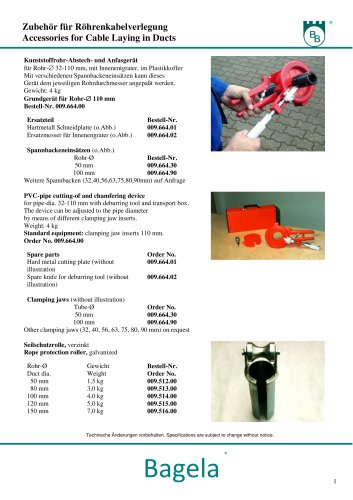

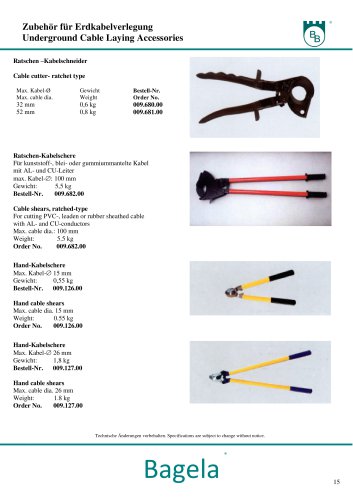

Cable and pipe cutter

2 Pages

-

Manhole cover lifter

2 Pages

-

Stringing gun EZ 100

2 Pages

-

Cable protection rollers

2 Pages

-

Cable protection bends

2 Pages

-

Glass fibre rods

3 Pages

-

Cable drum transport devices

1 Pages

-

Lifting jacks

5 Pages

-

Cable rollers

4 Pages

-

CPC

2 Pages

-

BA 7000F, BA 10000F

2 Pages

-

BA 4000

2 Pages

-

Microflow

2 Pages

-

Miniflow

2 Pages

-

Multiflow

3 Pages

-

Powerflow

3 Pages

-

BKS 1200

2 Pages

-

BKS 400

2 Pages

-

Tube coil reels

1 Pages

-

BRT 20

1 Pages

-

BRVT 17

1 Pages

-

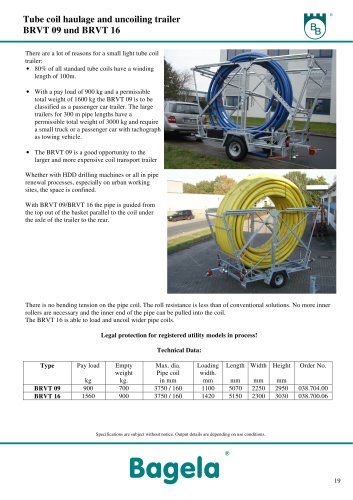

BRVT 09 and BRVT 16

1 Pages

-

BRT 65

2 Pages

-

BRT 25 - BRT 50

2 Pages

-

BTT 130.80V bis BTT 201.10V

2 Pages

-

BKT 18 up to BKT 80

3 Pages

-

RWF 1500

1 Pages

-

KW 3F and KW 4F

1 Pages

-

Reconstruction Technologies

2 Pages

-

RW 1500

1 Pages

-

RW 3000 - RW 4000 - RW 5000

2 Pages

-

Mounted Winches

2 Pages

-

softliner winch type RW 1500

1 Pages

-

W 2500 / W 3000

2 Pages

-

30/11 - 50/03

1 Pages

-

KW 1002 - KW 2002 - KW 3002

2 Pages

-

KTW 500 / KTW 1005

1 Pages

-

BTT 100.80 and BTT 160.20

1 Pages

Archived catalogs

-

RKW 3 - RKW 4 - RKW 5

2 Pages

-

KTW 1000

1 Pages