Website:

Badotherm Group

Website:

Badotherm Group

Catalog excerpts

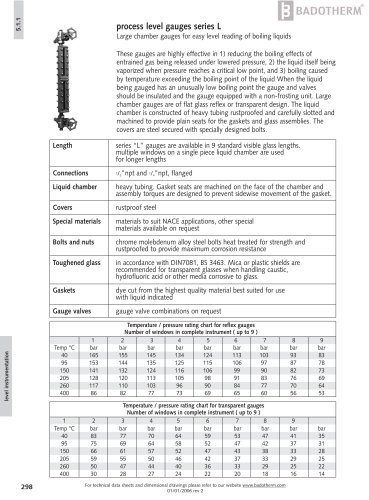

For technical data sheets and dimensional drawings please refer to our website www.badotherm.com 01/01/2006 rev 2 298 5.1.1 level instrumentation process level gauges series L Large chamber gauges for easy level reading of boiling liquids These gauges are highly effective in 1) reducing the boiling effects of entrained gas being released under lowered pressure, 2) the liquid itself being vaporized when pressure reaches a critical low point, and 3) boiling caused by temperature exceeding the boiling point of the liquid When the liquid being gauged has an unusually low boiling point the gauge and valves should be insulated and the gauge equipped with a non-frosting unit. Large chamber gauges are of flat glass reflex or transparent design. The liquid chamber is constructed of heavy tubing rustproofed and carefully slotted and machined to provide plain seats for the gaskets and glass assemblies. The covers are steel secured with specially designed bolts. Length series “L” gauges are available in 9 standard visible glass lengths. multiple windows on a single piece liquid chamber are used for longer lengths Connections 1/2”npt and 3/4”npt, flanged Liquid chamber heavy tubing. Gasket seats are machined on the face of the chamber and assembly torques are designed to prevent sidewise movement of the gasket. Covers rustproof steel Special materials materials to suit NACE applications, other special materials available on request Bolts and nuts chrome molebdenum alloy steel bolts heat treated for strength and rustproofed to provide maximum corrosion resistance Toughened glass in accordance with DIN7081, BS 3463. Mica or plastic shields are recommended for transparent glasses when handling caustic, hydrofluoric acid or other media corrosive to glass. Gaskets dye cut from the highest quality material best suited for use with liquid indicated Gauge valves gauge valve combinations on request Temperature / pressure rating chart for reflex gauges Number of windows in complete instrument ( up to 9 ) 1 2 3 4 5 6 7 8 9 Temp °C bar bar bar bar bar bar bar bar bar 40 165 155 145 134 124 113 103 93 83 95 153 144 135 125 115 106 97 87 78 150 141 132 124 116 106 99 90 82 73 205 128 120 113 105 98 91 83 76 69 260 117 110 103 96 90 84 77 70 64 400 86 82 77 73 69 65 60 56 53 Temperature / pressure rating chart for transparent gauges Number of windows in complete instrument ( up to 9 ) 1 2 3 4 5 6 7 8 9 Temp °C bar bar bar bar bar bar bar bar bar 40 83 77 70 64 59 53 47 41 35 95 75 69 64 58 52 47 42 37 31 150 66 61 57 52 47 43 38 33 28 205 59 55 50 46 42 37 33 29 25 260 50 47 44 40 36 33 29 25 22 400 30 28 27 24 22 20 18 16 14

Open the catalog to page 1All Badotherm Group catalogs and technical brochures

-

DLD Diaphragm Leak Detection

2 Pages

-

TC Temperature Compensator

2 Pages

-

US FH

3 Pages

-

BRC

3 Pages

-

EXT

3 Pages

-

BC

4 Pages

-

Thermowells

14 Pages

Archived catalogs

-

commercial catalogue 2006/07

324 Pages