Website:

Badotherm Group

Website:

Badotherm Group

Catalog excerpts

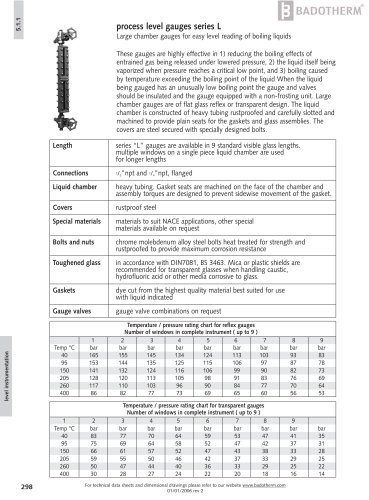

tubular level gauges series FF-2000 level gauges for low pressure and boiler drum applications Tubular glass level gauges comprise a length of 19 mm outside diameter drawn borosilicate glass tube fitted each end with an offset isolating valve to permit connection to a vessel. The series 20 and 60 valves can be supplied on this level gauge. The visible standard length with a single glass is to and including 2000 mm vessels. Longer lengths are available on application. To determine the following details subtract from centre to centre dimensions. Visible glass – centres distance minus 180 mm Maximum working pressure for Temperatures up to 65 °C Steam boiler services up to 218 °C Single glass length bar bar 200 29.3 20.6 250 28.3 20.6 300 27.6 20.6 350 26.6 20.0 400 25.6 19.3 450 24.6 18.9 500 23.8 18.3 600 21.7 17.2 Maximum working pressure varies with the length of the glass Tubular level gauges with glass length up to 600 mm are suitable for steam boiler applications, when installed in accordance with the requirements of the European norms. Isolating valve materials for series 20 and 60 Valve body machined from carbon steel forging Valve bonnet union type bonnet machined from carbon steel Valve trim renewable seat, plug / spindle and ballcheck manufactured in AISI316 Handwheel malleable iron Packing spindle packing, multi ring non-asbestos compatible with the service. glass gland packing, rubber / PTFE Carbon steel parts are all rust-proofed to provide maximum corrosion resistance Special materials available to suit specific liquid services Optional features and accessories Guard rod protectors 4 guard rods and holders to protect the glass from mechanical shocks Tubular glass protectors consists of holders and four sheets of Perspex glass of the proper length and width to fit Badotherm level gauge and valve assemblies Safety ball check valves can be furnished with a ball check for pressurized and vacuum service to provide positive isolation of liquid in the event of glass breakage. level instrumentation For technical data sheets and dimensional drawings please refer to our website www.badotherm.com 301 01/01/2006 rev 2 5.1.1

Open the catalog to page 1All Badotherm Group catalogs and technical brochures

-

DLD Diaphragm Leak Detection

2 Pages

-

TC Temperature Compensator

2 Pages

-

US FH

3 Pages

-

BRC

3 Pages

-

EXT

3 Pages

-

BC

4 Pages

-

Thermowells

14 Pages

Archived catalogs

-

commercial catalogue 2006/07

324 Pages