Catalog excerpts

M-Series® Mag Meter Model M-3000 Installation & Operation Manual IMPORTANT !!!! Read this manual before attempting any handling or installation of the meter. IOM-120-05 BadgerMeter, Inc. 53400-120 Rev. 5 9-10

Open the catalog to page 1

Disclaimer The user/purchaser is expected to read and understand the information provided in this manual, follow any listed Safety Precautions and Instructions and keep this manual with the equipment for future reference. The information in this manual has been carefully checked and is believed to be entirely reliable and consistent with the product described. However, no responsibility is assumed for inaccuracies, nor does Badger Meter Incorporated assume any liability arising out of the application and use of the equipment described. Should the equipment be used in a manner not specied by...

Open the catalog to page 2

NOTE: Do not remove the liner protector until installation. SAFETY PRECAUTIONS and INSTRUCTIONS 8. Storage: If the meter is to be stored, place it in its original container in a dry, sheltered location. Storage temperature ranges are: -4°F to 158°F (-20°C to 70° C). Safety considerations are emphasized by the placement of safety symbol icons on the product or next to important text, pictures or drawings throughout this manual. The symbols are: Rigging, Lifting, Moving Large Units DO NOT lift or move a meter via its amplier, junction box or cables. When and where this symbol is attached to...

Open the catalog to page 4

Use the sling-rigged method to lift large detectors into a vertical position while still crated. Use this method to position large detectors vertically into pipelines. Do not lift a detector with a forklift via the detector body between theflanges.The housing could be dented and/or damage caused to internal coil assemblies. Instructions Specific to Hazardous Area Installations These instructions apply to equipment covered by FM 1. The temperature range for fluids passing through the 2. The ambient temperature range surrounding the 3. The ambient temperature range surrounding the junction 4....

Open the catalog to page 5

Class t.Zorwi.AEK/ nAiaMOTS /\ Provides inlririsically sale «l«ClrOrla Client* Warning - SiAsriluNon or components may impair imnnsic safety Suiiable lorCLI Divi ABCOTS Provides rmrinsically sale elaclrodo oircuts warning ■ Subsiiiution of components may impair Imnnsic Safety ^ C r:or:rKH [WMAh 'K:' |h::ia| [^0 ;:<]Nrnoi I l)W(; IftH If)? O / For additional information regarding importation, equipment installation, equipment repair, equipment return or renewal parts, please contact: Badger Meter, Incorporated On the WEB: www.badgermeter.com or contact your local Badger Meter representative...

Open the catalog to page 6

METER/AMPLIFIER LOCATION, ORIENTATION and APPLICATIONS Remote Amplier Outdoor Location The amplier can be installed and operated outdoors. However, protection from the elements must be considered: 6. Verify both ends of the signal cables are securely fastened. 7. Place power and signal cables in separate conduit. 8. Place the meter where there is enough access for installation/maintenance purposes. 1. Be aware of the ambient environment and temperature ratings for the unit -4°F to 122°F (-20°C to 50°C). 2. If an indoor location is within 100 feet (30m) of the detector installation, consider...

Open the catalog to page 7

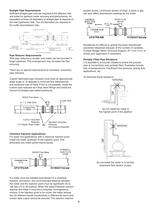

Straight Pipe Requirements Sufcient straight pipe runs are required at the detector inlet and outlet for optimum meter accuracy and performance. An equivalent of three (3) diameters of straight pipe is required on the inlet (upstream) side. Two (2) diameters are required on the outlet (downstream) side. spaced bursts, continuous stream of drips, a liquid or gas can also affect downstream readings by the meter. M-3000 Mag FLOWMETER D (Pipe Size) D (Pipe Size) FORWARD FLOW CHECK VALVE GLOBE VALVE BUTTERFLY VALVE PUMP 3xD 2xD MINIMUM STRAIGHT PIPE MINIMUM STRAIGHT PIPE 7xD MINIMUM STRAIGHT...

Open the catalog to page 8

To ensure proper unit operation, the mag meter impact ground (zero voltage reference) must be connected to the liquid media and to a good, solid earth ground. Perform grounding procedures after the meter is connected to the pipeline. FLOW RIGHT Conductive Pipe Grounding A grounding bolt is located on each mag meter ange. Drill and tap the pipeline anges on each side of the meter and install a grounding bolt to each. To ground the unit, attach a ground strap (provided) of copper wire, at least 12AWG size, between the grounding bolts on the meter anges and the bolts on the pipeline anges. Do...

Open the catalog to page 9

METER INSTALLATION PLANS and EXECUTION REMOTE MOUNT AMPLIFIER/DETECTOR WIRING Plan meter layout, location and installation. During installation, remember these important points: Remote Mount Amplier The remote mount amplier has three chambers and ve wire ports. The Junction Box and Connections Chambers and wiring ports provide amplier openings for wire, conduit, tool and hand access to amplier terminal blocks. Detector to amplier wires connect in the Junction Box Chamber. Amplier AC power and customer signal wires attach in the Connections Chamber. 1. Heed all safety notications. 2. Select...

Open the catalog to page 10

Electrode and Coil Wiring From Detector Junction Box to Remote Mount Amplier Juncton Box A remote mount unit requires electrode and coil cables, from the detector junction box to the amplier junction box, be enclosed in properly rated conduit. Use conduit ttings (not supplied) that are rated for Class I, Div 2 hazardous locations. 6. Run cable and conduit to Amplier junction box. Electrode Wiring in Amplier Junction Box To connect the electrode wires in the Amplier Junction Box: 1. Unscrew the amplier junction box chamber cover. If necessary, use a strap wrench. 2. Remove the protective...

Open the catalog to page 12

4. Connect conduit to junction box. Use a NEMA 6P ½ inch NPT tting. 5. Install protective plastic cover over terminal blocks. 6. Attach the amplier junction box chamber cover. Electrode Wires OUTPUT WIRING The Badger® M-3000 Meter converts liquid ow into electrical signal(s). With proper output wiring and amplier programming, the signal(s) are sent to, and used by, processing equipment used in operations or other procedures. Coil Wires Coil wiring in detector chamber Red to terminal labeled – Clear to terminal labeled – NOTE: Output wires and terminals are the same for meter mount or remote...

Open the catalog to page 13All Badger Meter catalogs and technical brochures

-

HR-E® LCD Encoder

2 Pages

-

Recordall® Disc Meters

8 Pages

-

RVL Series

8 Pages

-

VN2000 Flow Meters

8 Pages

-

Field Flow Calibrator

4 Pages

-

Body Leakage Tester

2 Pages

-

Measurable Results

12 Pages

-

Blancett Overview

8 Pages

-

Oil and Gas Market

8 Pages

-

Automotive Products

12 Pages

-

Model CB-30

2 Pages

-

4000 series

2 Pages

-

Test and Measurement

20 Pages

-

Cox Exact Dual Rotor

8 Pages

-

RTR

2 Pages

-

ADE®

2 Pages

-

HR-E® LCD

2 Pages

-

HR-E

2 Pages

-

SRI990 Analog Positioner

2 Pages

-

735 series

2 Pages

-

GALAXY® Water Products

2 Pages

-

Model M2000 Detector

2 Pages

-

Model M2000 Amplifier

2 Pages

-

Oval Gear Meter

1 Pages

-

M5000

44 Pages

-

M4000

36 Pages

-

M2000

60 Pages