Catalog excerpts

COMPOUNDS CVOC) GASEOUS EFFLUENTS

Open the catalog to page 1

BABCOCK WAIMSOIM SOLUTIONS TRGUGHOUT BABCOCK WANSON 94550 Chevilly Larue - France United Kingdom United Kingdom Barrio San Martin Avda. Pinoa S/N Central Europe Czech Republic BABCOCK WANSON BABCOCK WANSON Piste d'Ain Bordja

Open the catalog to page 2

BABCOCK WANSON The companies forming our International Group combine unparalleled experience and expertise in Thermal Engineering applications gained over 60 years of progressive development. Group companies are active in Italy, France, United Kingdom, Spain, Portugal, Switzerland, Morocco and Central Europe. Our Group activities are principally in the fields of process air treatment, steam and thermal fluid industrial boilers and water treatment. With many hundreds of installations for VOC and Odour abatement we hold an ideal position to provide complete and tailor made solutions for each...

Open the catalog to page 3

Recuperative Thermal Oxidisers • Pressurised high temperature water • Thermal Fluid. COMBUSTION CHAMBER HEAT RECOVERY UNIT The simplest and safest method of treating polluting VOCs is to oxidise them by heating in a combustion chamber at a temperature in the range 700-M100 °C (typically about 750 °C) with a residence time of between 0.6 and 2.0 seconds (typically about 0.8"). The process plant includes: A fan with inverter speed regulation to vary the input Control panel for system regulation with PLC for the management of the operating cycles plus operator interface panel with LCD touch...

Open the catalog to page 4

Flexible Packaging Printing Effluent gas • 18,000 Nm3/h • Thermal Fluid Heat Recovery Pharmaceutical Industry • Twin Oxidisers with recovery to air and water • Effluent gas • 6,000 Nm3/h Petro-Chemical Plant Oxidiser with integrated thermal fluid heat recovery Leather cloth Manufacturing • Effluent gas 20,000 Nm3/h • Thermal Fluid Heat Recovery 3

Open the catalog to page 5

Ceramic Regenerative Oxidisers Ceramic Regenerative Oxidisers are used in cases where the requirement for heat recovery does not exist or is too small to justify employing a Thermal Recovery Oxidiser. The Regenerative Oxidiser includes: • Effluent fan with automatic output control system. • Heat storage towers filled with ceramic, which may be saddles or honeycomb structures selected to suit the • A system of automatic valves for effluent distribution through the towers. These are of exclusive Babcock Wanson design and manufacture. The valves can be fitted under or next to the towers,...

Open the catalog to page 6

EXHAUST GAS OUTLET AIR PROCESS INLET AIR PROCESS BY-PASS Regenerative Oxidisers can be constructed in the following configurations: • 2 tower • 2 tower plus compensation tower to reduce the emission peaks • 3 tower to achieve lowest emission levels • 5 tower for high volumes of effluent S2 S1 INLET GAS FRESH AIR The choice depends on: AIR PROCESS INLET AIR PROCESS BY-PASS • Concentration and nature of the VOC to be treated • Available space EXHAUST GAS OUTLET The following chart indicates the rate of VOC emission for the different arrangements. S1 S2 VOC EMISSION INLET GAS mg/Nm FRESH AIR...

Open the catalog to page 7

Regenerative Oxidiser with heat recovery In many cases the polluted air contains very high concentrations of VOC demanding the disposal of large quantities of heat. It is therefore essential to provide a control system for the temperature in the combustion chamber (hot gas by-pass) and sometimes it can be beneficial to fit an additional heat recovery unit to heat air, water or thermal oil. Babcock Wanson specialise in the design and manufacture of these heat recovery systems, which have been part of our production programme for many years. FRESH AIR Fabric coating • 50,000 Nm3/h Thermal...

Open the catalog to page 8

Rotoconcentrator When the quantity of the air to be treated is very high and the concentrations of VOC very low, it is necessary to employ a design which reduces the volumes of air to be treated in the Oxidiser and at the same time increases the concentration of VOC in order to reduce operational and capital costs. The rotoconcentrator with zeolite allows this to be achieved, reducing the volume of air and increasing proportionally the concentration of VOC. The rotoconcentrator is coupled to a Thermal Recovery Oxidiser or a ceramic Regenerative Oxidiser with reduced flow, which treats an...

Open the catalog to page 9

Deodorising Oxidisers Recovery and Regenerative Oxidisers are also utilised to eliminate odours and vapour emissions generated by many production processes. These are specially designed plants tailored to meet the particular requirements of these industrial processes. Babcock Wanson is the leading company in Europe in this field having completed many successful installations operating in the following industries: • Animal tallow production (rendering). Industrial frying processes (potatoes, • Food industries. • Various chemical processes. • Coffee and barley roasting. • Rubber vulcanising...

Open the catalog to page 10

RENDERING Our Deodorising Oxidisers are well known all over Europe as the best technology to eliminate the odours from the effluents of: cookers, sterilisers, presses, decanters, material storage hoppers, etc. The option to select a system with heat recovery or a ceramic regenerative oxidiser is determined by the specific requirements of each customer and according to the quantity of vapour and air to be treated. A major factor in the choice is the type of fuel that is available e.g. gas, heavy fuel oil or tallow. Industrial frying of vegetable oils and meats These normally use COMBI...

Open the catalog to page 11

Application fields Babcock Wanson plants, which have been shown to achieve emission levels CTOC, CO NOx) in line with diverse European regulations are employed in a wide variety of applications, such as: • Printing on metal cans and containers with products containing ketones, acetates and hydrocarbons. • Flexible packaging manufacture (paper, carton, plastic films and aluminium), where coating, laminating and printing take place with inks containing acetates, glycols and hydrocarbons, together with solvent based laminate adhesive. • Timber composite production using solvent based sprays...

Open the catalog to page 12All Babcock Wanson catalogs and technical brochures

-

e-Pack

2 Pages

-

VAP PREMIUM

2 Pages

-

VAP RR

2 Pages

-

STEAM SOLUTIONS

12 Pages

-

TPC-B THERMAL FLUID HEATER

2 Pages

-

BWR FIRETUBE STEAM BOILER

2 Pages

-

BWD FIRETUBE STEAM BOILER

2 Pages

-

NBWB FIRETUBE STEAM BOILER

2 Pages

-

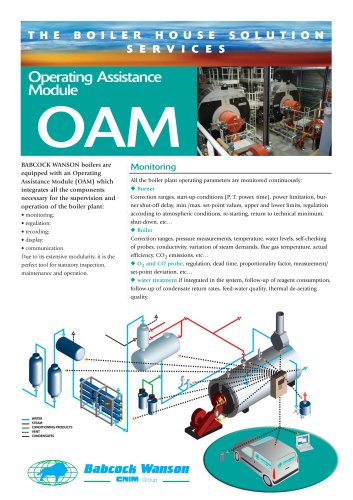

The Boiler House Solution

2 Pages

-

WDF Direct Fired Air Heaters

2 Pages

-

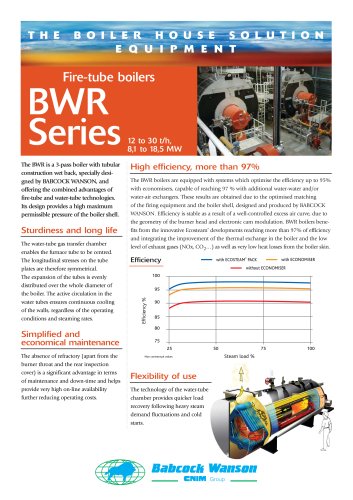

Fire tube steam boiler BWR

2 Pages

-

Thermal fluid Heaters TPC

2 Pages

-

Fire Tube Boilers BWD

2 Pages

-

Hot water boilers EPC AC

2 Pages

-

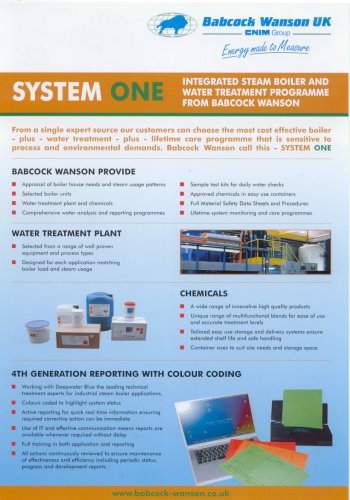

System One

2 Pages

-

Thermal fluid Heaters EPC-H

2 Pages

-

Thermal fluid Heaters TPC LN

2 Pages

-

Thermal fluid Heaters TPC-H

2 Pages

-

EUROSTEAM

2 Pages

-

Process air heaters

2 Pages

-

Air Vein burners

2 Pages

-

Thermal fluid Heaters EPC-ES

2 Pages

-

Hot water boilers HW Pack

4 Pages

-

Fire tube steam boiler BWB

2 Pages

-

Energy optimization

2 Pages

-

Thermal Fluid Heater TPC-LN

2 Pages

-

Thermal Fluid Heater TPC

2 Pages

Archived catalogs

-

Fire-tube Boiler - BWD

2 Pages

-

BW Energy Optimisation

2 Pages

-

Fire-tube Boiler - BWR

2 Pages

-

Fire-tube Boiler - BWB

2 Pages