Catalog excerpts

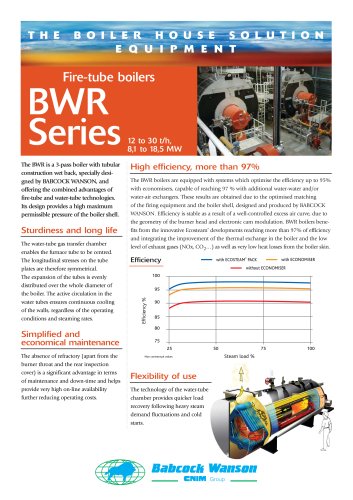

Fire-tube boilers The BWR is a 3-pass boiler with tubular construction wet back, specially designed by BABCOCK WANSON, and offering the combined advantages of fire-tube and water-tube technologies. Its design provides a high maximum permissible pressure of the boiler shell. Sturdiness and long life The water-tube gas transfer chamber enables the furnace tube to be centred. The longitudinal stresses on the tube plates are therefore symmetrical. The expansion of the tubes is evenly distributed over the whole diameter of the boiler. The active circulation in the water tubes ensures continuous cooling of the walls, regardless of the operating conditions and steaming rates. High efficiency, more than 97% The BWR boilers are equipped with systems which optimise the efficiency up to 95% with economisers, capable of reaching 97 % with additional water-water and/or water-air exchangers. These results are obtained due to the optimised matching of the firing equipment and the boiler shell, designed and produced by BABCOCK WANSON. Efficiency is stable as a result of a well-controlled excess air curve, due to the geometry of the burner head and electronic cam modulation. BWR boilers benefits from the innovative Ecosteam® developments reaching more than 97% of efficiency and integrating the improvement of the thermal exchange in the boiler and the low level of exhaust gases (NOx, CO2…) as well as very low heat losses from the boiler skin. with ECOSTEAM® PACK with ECONOMISER Simplified and economical maintenance The absence of refractory (apart from the burner throat and the rear inspection cover) is a significant advantage in terms of maintenance and down-time and helps provide very high on-line availability further reducing operating costs. Flexibility of use The technology of the water-tube chamber provides quicker load recovery following heavy steam demand fluctuations and cold starts. Steam load %

Open the catalog to page 1

Super heated steam The optimisation of the design allows the integration of a superheating module in the front box. The temperature is varying with the burner load and therefore the temperature of superheated steam is lower with a lower load. Steam quality The steam separator located inside the boiler shell under the steam outlet and the rapid burner response time ensure that the level of dryness is high (99.5%). This boiler design offers better safety with respect to low water level, and eliminates the risks of internal fouling (sludge accu- mulation in the bottom of the boiler). BABCOCK...

Open the catalog to page 2All Babcock Wanson catalogs and technical brochures

-

e-Pack

2 Pages

-

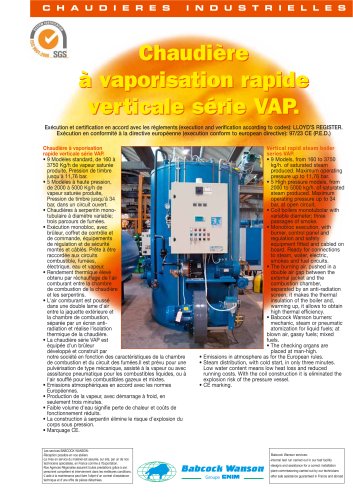

VAP PREMIUM

2 Pages

-

VAP RR

2 Pages

-

STEAM SOLUTIONS

12 Pages

-

TPC-B THERMAL FLUID HEATER

2 Pages

-

BWR FIRETUBE STEAM BOILER

2 Pages

-

BWD FIRETUBE STEAM BOILER

2 Pages

-

NBWB FIRETUBE STEAM BOILER

2 Pages

-

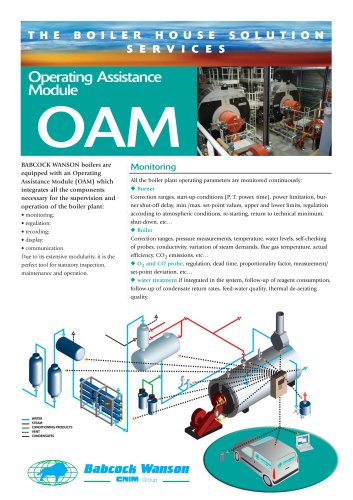

The Boiler House Solution

2 Pages

-

WDF Direct Fired Air Heaters

2 Pages

-

Thermal fluid Heaters TPC

2 Pages

-

Fire Tube Boilers BWD

2 Pages

-

Hot water boilers EPC AC

2 Pages

-

System One

2 Pages

-

Thermal fluid Heaters EPC-H

2 Pages

-

Thermal fluid Heaters TPC LN

2 Pages

-

Thermal fluid Heaters TPC-H

2 Pages

-

EUROSTEAM

2 Pages

-

Process air heaters

2 Pages

-

Air Vein burners

2 Pages

-

Thermal fluid Heaters EPC-ES

2 Pages

-

Hot water boilers HW Pack

4 Pages

-

Fire tube steam boiler BWB

2 Pages

-

Energy optimization

2 Pages

-

Thermal Fluid Heater TPC-LN

2 Pages

-

Thermal Fluid Heater TPC

2 Pages

Archived catalogs

-

Fire-tube Boiler - BWD

2 Pages

-

BW Energy Optimisation

2 Pages

-

Fire-tube Boiler - BWR

2 Pages

-

Fire-tube Boiler - BWB

2 Pages