Catalog excerpts

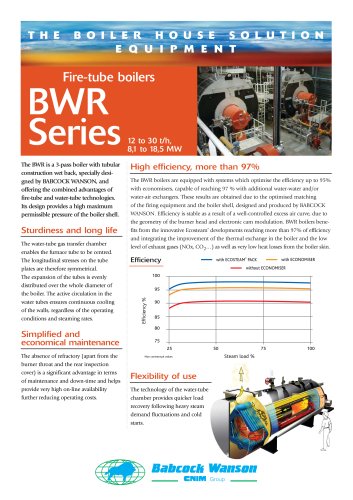

S T E A M B L O C BWD Series Fire-tube boilers 1000 to 10,000 kg/hr 682 to 6793 kW Strength and long life from good design The flue gas reversal chamber located co-axially with the furnace tube contributes to the long life of the boiler by optimising the distribution of mechanical stresses. This is particularly important where boilers operate intermittently or at low load in stop start mode. Easy accessibility of the tubes provides better and lower cost maintenance The outer section of the transfer chamber which is cooled by the water, is equipped with a double compartment. This particular BABCOCK WANSON design improves the heat transfer and allows direct access to the first tube nests. This eliminates the frequent problem of stress affecting the tie rods on conventional wet back boilers. Compactness and flexibility The centred furnace tube and the optimised distribution of the second and third pass convection tubes enables best possible use of site space. BABCOCK WANSON burners provide a wide operating range, with turn down ratios of up to 8:1 when firing on gas. High efficiency; 95% with optional economiser The optimised matching of the BWD boiler shell and the Babcock Wanson burner enables an efficiency of up to 95% with economiser. A constant efficiency is obtained from 30 to 100% load over the whole modulation range thanks to stable combustion due to the geometry of the burner head. with ECONOMISER with ECOSTEAM® PACK The BWD is a 3-pass semi-wet back fire tube boiler exclusively designed by BABCOCK WANSON. Steam load % Steam quality The steam separator located inside the boiler shell under the steam outlet and the rapid burner response time, ensure that the dryness guarantee is 99.5%. Operating modes Equipment options include control and instrumentation for either fully manned, supervised or fully unattended operation.

Open the catalog to page 1

Energy and the environment To improve efficiency, reduce fuel and electrical consumption and also to achieve very low NOx emission, BABCOCK WANSON offers the Ecosteam pack on this boiler series further reducing the operating costs of this already efficient boiler range. STEAMBLOC BWD - performance and dimensions models total water volume in litres steam output in t/h output in kW dimensions in mm Quality and approvals BABCOCK WANSON is certified to ISO 9001; the boilers have been approved by many international organisations such as LLOYDS REGISTER, APAVE, BUREAU VERITAS, SGS, ASIT, BSI,...

Open the catalog to page 2All Babcock Wanson catalogs and technical brochures

-

e-Pack

2 Pages

-

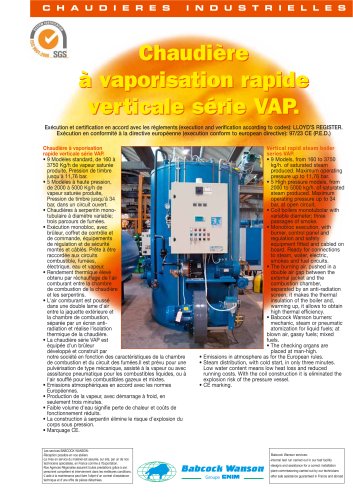

VAP PREMIUM

2 Pages

-

VAP RR

2 Pages

-

STEAM SOLUTIONS

12 Pages

-

TPC-B THERMAL FLUID HEATER

2 Pages

-

BWR FIRETUBE STEAM BOILER

2 Pages

-

BWD FIRETUBE STEAM BOILER

2 Pages

-

NBWB FIRETUBE STEAM BOILER

2 Pages

-

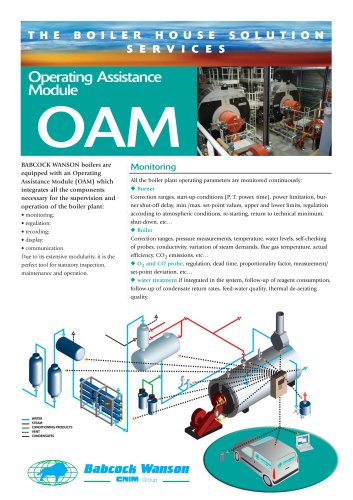

The Boiler House Solution

2 Pages

-

WDF Direct Fired Air Heaters

2 Pages

-

Fire tube steam boiler BWR

2 Pages

-

Thermal fluid Heaters TPC

2 Pages

-

Hot water boilers EPC AC

2 Pages

-

System One

2 Pages

-

Thermal fluid Heaters EPC-H

2 Pages

-

Thermal fluid Heaters TPC LN

2 Pages

-

Thermal fluid Heaters TPC-H

2 Pages

-

EUROSTEAM

2 Pages

-

Process air heaters

2 Pages

-

Air Vein burners

2 Pages

-

Thermal fluid Heaters EPC-ES

2 Pages

-

Hot water boilers HW Pack

4 Pages

-

Fire tube steam boiler BWB

2 Pages

-

Energy optimization

2 Pages

-

Thermal Fluid Heater TPC-LN

2 Pages

-

Thermal Fluid Heater TPC

2 Pages

Archived catalogs

-

Fire-tube Boiler - BWD

2 Pages

-

BW Energy Optimisation

2 Pages

-

Fire-tube Boiler - BWR

2 Pages

-

Fire-tube Boiler - BWB

2 Pages