Catalog excerpts

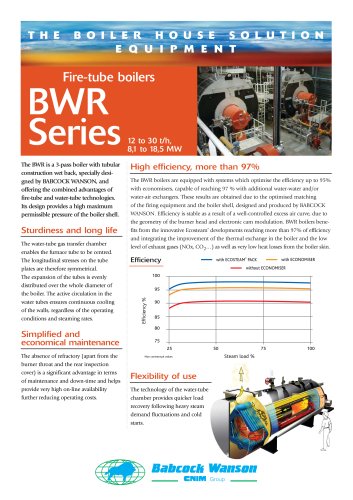

Babcock Wanson BWRFIRETUBE STEAM BOILER THE COMPLETE BOILER HOUSE SOLUTION BWR - STEAM OUTPUTS FROM 10 000 KG/H TO 30 000 KG/H ENVIRONMENTALLY FRIENDLY LOW FUEL CONSUMPTION ■ Perfect Boiler-Burner match The perfect match between the BWR boiler shell and Babcock Wanson burner ensures reliable and efficient operation in standard construction. Efficiencies in excess of 98% (R-Eco) and 105% (Condensing) can be achieved when fitted with a Babcock Wanson matched economiser and heat recovery system. ■ Consistently high efficiency Consistent high thermal efficiency throughout the firing range is a key feature from Babcock Wanson. Digital micromodulation control with burner head geometry specifically designed to suit the BWR boiler provides very high turndown ratios with accurate control of excess air and lowest practicable operating costs. BABCOCK WANSON are at the forefront of boiler and burner design and construction driving down emissions and exceeding the requirements of statutory regulations. ■ Low electrical consumption Electrical power consumption is reduced by 30% to 50% by the use of variable speed control. RELIABLE & SAFE DESIGN ENVIRONMENTALLY FRIENDLY FLEXIBLE SOLUTION FULL RANGE OF ANCILLARY EQUIPMENT WHY CHOOSE THE BWR BOILER FROM BABCOCK WANSON? r ■ Combustion Air Pre-Heaters ■ Dual and mixed fuel firing options ■ O2 and CO trim options ■ Simple unattended operation ■ Complete steam system solutions ■ High efficiency - Low NOx burners ■ High burner turndown ratios ■ Simple access for ease of maintenance ■ Robust design for very long life ■ Flue gas Heat Recovery V_._

Open the catalog to page 1

BWR FIRETUBE STEAM BOILER REDUCED OPERATING COST ••Robust Construction for long life BWR Boilers are three pass design and include a tubular construction flue gas reversal chamber. This proven feature, unique to Babcock Wanson, enhances water circulation thereby eliminating the risks of internal fouling (sludge accumulation in the bottom of the boiler). Furnace tie rods are not required and uniform shell expansion gives the flexibility to meet large steam load changes with minimal operational stress. ••Simplified Maintenance The flue gas reversal chamber is fully water cooled ensuring high...

Open the catalog to page 2All Babcock Wanson catalogs and technical brochures

-

e-Pack

2 Pages

-

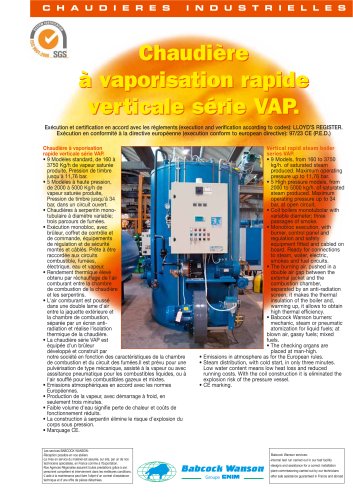

VAP PREMIUM

2 Pages

-

VAP RR

2 Pages

-

STEAM SOLUTIONS

12 Pages

-

TPC-B THERMAL FLUID HEATER

2 Pages

-

BWD FIRETUBE STEAM BOILER

2 Pages

-

NBWB FIRETUBE STEAM BOILER

2 Pages

-

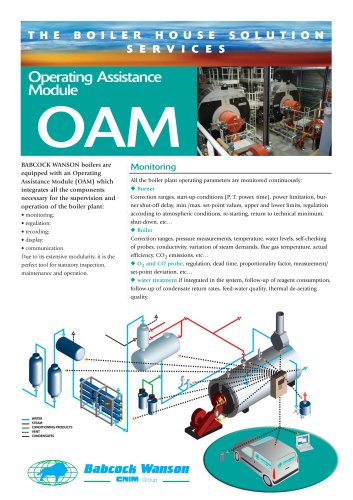

The Boiler House Solution

2 Pages

-

WDF Direct Fired Air Heaters

2 Pages

-

Fire tube steam boiler BWR

2 Pages

-

Thermal fluid Heaters TPC

2 Pages

-

Fire Tube Boilers BWD

2 Pages

-

Hot water boilers EPC AC

2 Pages

-

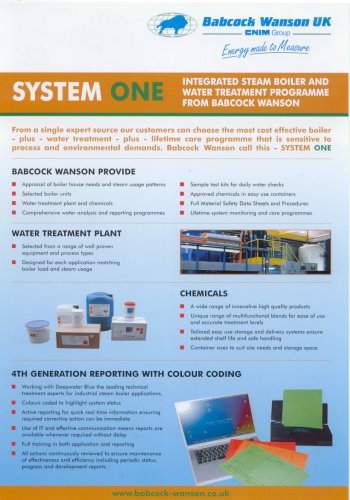

System One

2 Pages

-

Thermal fluid Heaters EPC-H

2 Pages

-

Thermal fluid Heaters TPC LN

2 Pages

-

Thermal fluid Heaters TPC-H

2 Pages

-

EUROSTEAM

2 Pages

-

Process air heaters

2 Pages

-

Air Vein burners

2 Pages

-

Thermal fluid Heaters EPC-ES

2 Pages

-

Hot water boilers HW Pack

4 Pages

-

Fire tube steam boiler BWB

2 Pages

-

Energy optimization

2 Pages

-

Thermal Fluid Heater TPC-LN

2 Pages

-

Thermal Fluid Heater TPC

2 Pages

Archived catalogs

-

Fire-tube Boiler - BWD

2 Pages

-

BW Energy Optimisation

2 Pages

-

Fire-tube Boiler - BWR

2 Pages

-

Fire-tube Boiler - BWB

2 Pages