Website:

b+b Automations- und Steuerungstechnik GmbH

Website:

b+b Automations- und Steuerungstechnik GmbH

Group: b+b group

Catalog excerpts

Data sheet Lab PlateMaster Pro Overview Description This fully automatic Petri dish labelling system with integrated sorting logic offers the greatest possible flexibility for the user. It allows adaptation to different requirements and product variants, as different Petri dish sizes can be processed simultaneously. The machine has been specifically designed for use in laboratories with or without a LIMS system (Laboratory Information and Management System). It features a mobile base frame and compact design to fit through narrow laboratory doors. The Lab PlateMaster Pro can print various types of labels and codes, such as 1D and 2D barcodes as well as QR and Data matrix codes along with human readable text. The machine is also able to create special markings for specific applications, such as temperature or sterilization indicators. In the basic configuration, the machine is available with 5 fixed and 5 automatic stacking magazines. The conveyors of the automatic stacking magazines transport the stacked „raw material“ from the magazines to the de-stacking position. They have a length of approx. 500 mm and are designed for up to 2 different Petri dish sizes. For changeover, the additional guide rails are simply folded down. Each belt is equipped with separate web dividers and a separator to unload the Petri dishes onto the labelling belt. A mechanical lid lifting system allows the lids to be lifted (without foreign objects entering) to partially apply the label under/behind the edge of the lid if required. Figure 1: Overall view Lab PlateMaster Pro With a print resolution of 600 dpi, the label printing and application unit applies labels to the circumference of the Petri dish. It can process label rolls with a diameter of up to 305 mm and a maximum label width of 58 mm. After labelling, the Petri dishes are moved to the stacking device at the outlet of the conveyor belt. This allows stacking of a variable number of Petri dishes (up to 13 depending on the LIMS order). The stacked dishes are transported on the return outfeed conveyor belt.

Open the catalog to page 1

Technical Data Number of stacking magazine 5 fixed stacking magazines 5 automatic stacking magazines Possible codes 1D or 2D barcodes, QR codes, data matrix codes or text labels The return outfeed belt transports the stacked Petri dishes to the front of the system, where they can be removed manually by the operator. Control system The system has a 15.6“ touch panel that allows intuitive operation and interaction with the system. It offers user-friendly program and parameter selection, customizable help texts and product images, and easy viewing of application parameters and counters....

Open the catalog to page 2All B+b Automations- und Steuerungstechnik GmbH catalogs and technical brochures

-

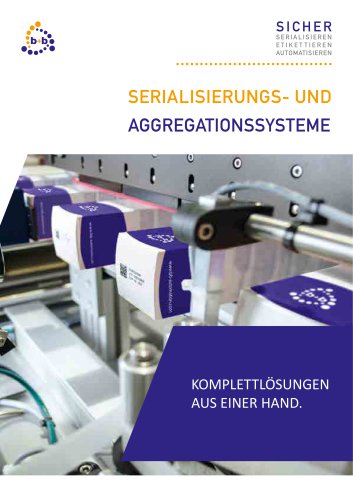

Brochure of the company

12 Pages

-

FIAVis unlimited (option)

4 Pages

-

EIBWeiche LAN

1 Pages

-

EIBWeiche serial

1 Pages

-

KNXGuard user defined

1 Pages

-

EIBAnalyzer

1 Pages

-

EIBWeiche USB

1 Pages

-

Modular Software Serialisation

15 Pages

-

Print- and apply systems

5 Pages

-

Print and apply systems

5 Pages