Catalog excerpts

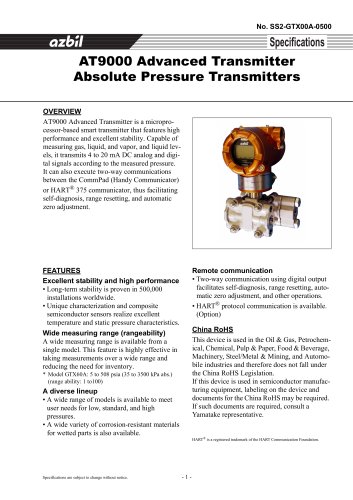

PTG series Smart Pressure Transmitter Model PTG71 / PTG72 OVERVIEW The Smart Pressure Transmitter model PTG is a high- performance, highly reliable gauge pressure transmitter. Based on Azbil Corporation's proven Smart Transmitter technologies, the model PTG offers improved performance and reliability with size, weight and cost advantages. An optional, built-in digital indicator allows the pressure transmitter to be used in a wide variety of applications. The model PTG can also enable two-way communications between HART 375 communicator, and, via DE protocol, a TDCS3000 or 3000X and a database, thus facilitating self-diagnosis, range resetting, and automatic zero adjustment operations. FEATURES Compact and lightweight • Approx. 0.9 kg (Screw connection type) Broad range setting • Range from -100 kPa to +50 MPa. • Span from 2.0 kPa to 50 MPa. Note) Screw connection type. Covered with five ranges. Remote communication Any range can be set using the Smart communicator or the HART communicator (available separately). This further increases range flexibility and keeps inventory down. Built-in digital indicator The built-in digital indicator option effectively checks output on site. C€ CE mark Model PTG71G screw type Type of protection • Water and dust proof for IEC IP67 • FM Explosionproof • FM Dust-ignition-proof • FM Intrinsically safe • KOSHA Flameproof • NEPSI Flameproof • NEPSI Dust ignition-proof • ATEX Flameproof China RoHS This device is used in the Oil & Gas, Petrochemical, Chemical, Pulp & Paper, Food & Beverage, Machinery, Steel/Metal & Mining, and Automobile industries and therefore does not fall under the China RoHS Legislation. If this device is used in semiconductor manufacturing equipment, labeling on the device and documents for the China RoHS may be required. If such documents are required, consult an Azbil Corp. representative. Specifications are subject to change without notice. - 1 - 18th edition

Open the catalog to page 1

Azbil Corporation External views of the PTG series Model PTG7_G (Screw type) Model PTG7_B (Flush diaphragm type) Model PTG7_T (Remote seal with ferrule clamp type) Model PTG7_S (Ferrule clamp type) Model PTG7_K (Ferrule clamp type with cooling tower) Model PTG7_S (Ferrule cap nut type) Model PTG7_F (Flange type) Model PTG7_K (Ferrule cap nut type with cooling tower) Model PTG7_T (Remote seal with ferrule cap nut type)

Open the catalog to page 2

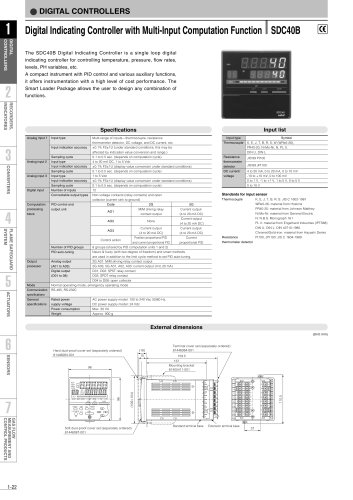

Azbil Corporation COMMON SPECIFICATIONS Output / Communication Model PTG71 • Analog output (4 to 20 mA DC) with SFN communication Explosionproof for Class I, Division 1, Groups A, B, C and D, T4, ambient temperature = 60°C Dust-ignition for Class II and III, Division 1, Groups E, F and G, T6 ambient temperature = 60°C, Type 4X Response speed FM Intrinsically safe approval Intrinsically safe for Class I, II, III, Division1, Group A, B, C, D, E, F, G T4 / Class I, Zone 0, AEx ia IIC T4 Vibration Tolerance • Analog output (4 to 20 mA DC) with HART protocol • DE output with CommStaff...

Open the catalog to page 3

Oil and water free finish Oil and water are removed from the wetted parts before shipment. Electrolytic grinding (For ferrule type only) The surface of the wetted parts is smoothed by electrolytic grinding. Passive state finish (For ferrule type only) The surface of the wetted parts is treated with a passive state finish to form a protective film to increase resistance to corrosion. Test report The test report indicates the results of appearance, I/O characteristics, insulation resistance, and breakdown voltage tests. Material certificate The material certificate shows the chemical...

Open the catalog to page 4

Azbil Corporation Working range of negative pressure 1000 Normal operating range (T: - 40 C to -110 C) 100 Figure 3 Minimum working pressure for combination of model PTG__S or model PTG__T or model PTG__B or PTG__F and propylene glycol. Unusable range (T: 150 to 155 C) Unusable range (T: -20 to -10 C) 1000 Normal operating range (T: - 40 C to -110 C) Temperature at wetted parts: T ( C) Figure 2 Minimum working pressure for model PTG__G. Unusable range Normal operating range (T: 110 C to 125 C) (T: - 10 C to -110 C) Temperature at wetted parts: T ( C) Temperature at wetted parts: T ( C)...

Open the catalog to page 5

Transmitter handling notes To get the most from the performance this transmitter can offer, please use it properly noting the points mentioned below. Before using it, please read the Instruction Manual. Transmitter installation notes • When installing the transmitter, ensure that gaskets do not protrude from connecting points into the process (such as adapter flange connection points and connecting pipes and flanges). Gasket protrusion may result in leaks and output errors. • Do not use the transmitter outside its defined pressure, temperature, and connection specifications. A serious...

Open the catalog to page 6

Ambient temperature limits Normal operating range Transportation and storage conditions -30 to +80°C Temperature range of wetted parts Measuring span / Setting range / Max. working pressure Water and dust proof Note) * 62.5 MPa for explosion-proof type Fill fluid Ambient humidity limits 5 to 100% RH Accuracy / Temperature effect Model PTG7_ G- _3 Accuracy *1 Materials Fill fluid • Silicone oil (for general purpose models) • Fluorine oil (for oxygen and chlorine models) Wetted parts Diaphragm SUS316L Others SUS316 Case Aluminum alloy Weight Approx. 0.9 kg Process connection • G1/2...

Open the catalog to page 8

MODEL SELECTION Smart Pressure Transmitter model PTG7XG Process connection: Screw type Measuring span: 2.0 to 100 kPa, 40 to 400 kPa, 0.2 to 2 MPa, 1 to 10 MPa, 5 to 50 MPa Model number structure: Basic model number - selection - Option1 - Option2 Note) *1 Not applicable for ATEX Flame proof “V” in the Type ofprotection. *2 The oil free finish or the water and oil free finish in the Option1 must be selected. *3 Applicable only for water and dust proof “N” and FM intrinsically safe “E” in the Type ofprotection. *4 “Built-in digital indicator” in the Option 1 must be selected.

Open the catalog to page 9All Azbil North America catalogs and technical brochures

-

NX-D25

2 Pages

-

NX-CB2

1 Pages

-

NX-CL1/CL2/TL1/TR1

1 Pages

-

RN748A

1 Pages

-

HM

1 Pages

-

ECM3000 Control Motor

8 Pages

-

Multi-Loop Controller SDC46A

2 Pages

-

Single Loop Controller SDC25

2 Pages

-

Single Loop Controller SDC15

2 Pages

-

YYU4 Simple Thermocouple

1 Pages

-

Fiber Units HPF Series

26 Pages

-

FL2 Series

6 Pages

-

LJM-D series

4 Pages

-

BZ Series Basic Switch

9 Pages

-

CMG Series Gas Flow Monitor

4 Pages

-

MCF Series Air Flow Meter

2 Pages

-

MAGNEW Series

3 Pages

-

HP100

10 Pages

-

HPX

10 Pages

-

HPX-AG

20 Pages

-

APT

2 Pages

-

APM

6 Pages

-

FL7M

10 Pages

-

ATT70

8 Pages

-

WaterMAG

8 Pages

Archived catalogs

-

MagneW 3000 Plus CA2-MGG-01

4 Pages

-

MagneW 3000 PLUS HENRI

2 Pages

-

MagneW Two-Wire Plus

20 Pages