Catalog excerpts

No. SS2-MTG300-0100 Specifications MagneW Two-wire PLUS+ Smart Two-wire Electromagnetic Flowmeter Model MTG18A (Integral type) Model MTG14C/MTG18B (Remote type) The MagneW Two-wire PLUS+ is a high performance electromagnetic flowmeter based on field proven Azbil Corporation's two-wire loop powered technology. The MagneW Two-wire PLUS+ offers the stable and accurate measurement of a traditional magflow meter with low power consumption. The result is a lower overall cost of ownership. FEATURES Two-wire operation MagneW Two-wire PLUS+ improves its noise immunity performance by 700% maximum and 250% in average. For the spike noise, MagneW Two-wire PLUS+ improves its noise immunity performance in 250% in average. High accuracy and stable output MagneW Two-wire PLUS+ provides high accuracy (± 0.5% of rate) and its output is as stable as current four wired magnetic flowmeters. Minimum measurable fluid conductivity The MagneW Two-wire PLUS+ offers a minimum process fluid conductivity of 10p,S/cm which is the best among two-wire magflow meters thereby maximizing applicability. Wider range in size MagneW Two-wire PLUS+ offers wider range in detector size. Detector size: 2.5 to 200 mm. Wafer and flange style, integral and remote style available The MagneW Two-wire PLUS+ is available integral or remote, flanged or wafer, making the selection of the right meter for the application simple. Electrode status diagnostic function The MagneW Two-wire PLUS+ offers the diagnostic function for the electrode condition. It diagnoses the Empty pipe condition or scale on electrode condition. APPLICATIONS • Corrosive liquid measurement • Chemical solution measurement • Drainage/waste disposal fluid measurement • Drinking water and waste water service • Industrial/agricultural water measurement • Seawater measurement

Open the catalog to page 1

FUNCTIONAL SPECIFICATIONS Enclosure rating NEMA TYPE 4X, IEC IP67 Hazardous Areas certifications Integral type FM approval <for Division 1> Class I, Division 1, Groups A, B, C & D, T4; Class II, Division 1, Groups E, F & G, T4; Class III, T4, -20°C < Tamb < +60°C <for Division 2> Nonincendive for Class I, Division 2, Groups A, B, C & D, T4; Class II, Division 2, Groups F & G, T4; Class III, T4; Class I, Zone 2, Group IIC, T4, -20°C < Tamb < +60°C CSA certification <for Division 1> Class I, Division 1, Groups A, B, C & D, T4; Class II, Division 1, Groups E, F & G, T4; Class III, T4, -20°C <...

Open the catalog to page 2

Flow unit Volume flow: m3, L, cm3, G (gallon), mG, kG, B (barrel), IG (imperial gallon), mIG, kIG Mass flow: t, kg, g, lb Time: d, h, min., s Display Display: LCD Main display: 7-segment, 8 digits Sub display: 16 digits, 2 lines Display contents: Simultaneously displays % flow rate, Actual flow rate (eng. unit) and Totalized value. Data setting Operation by four key switches Damping Adjustable between 0.5 and 199.9 seconds. Low flow cutoff Adjustable between 0 and 10% of setting range. Below selected value, output is driven to the zero flow rate signal level. Dropout Adjustable between 0...

Open the catalog to page 3

Lightning protection 12 kV, 1000A Equipped with the lightning arrester in the power source and external output terminals. Power failure An EEPROM retains data record of totalized value when pulse output is used (retention period approximately 10 years). Power supply 15.6 to 42V DC (without communication) 21.05 to 42V DC (with communication) Current capacity: 24mA min. In case of current capacity is 22mA, the voltage must be 15.6V minimum. Size Wafer style 25, 40, 50, 65, 80, 100 mm (1, 1/, 2, 2/, 3, 4 inches) Flange style 2.5, 5 mm (0.1, 0.2 inch) (Model MTG18A only) Temperature range and...

Open the catalog to page 4

Vs = velocity of setting range (m/s) PERFORMANCE SPECIFICATIONS Analog output accuracy Size: 2.5, 5 mm (0.1, 0.2 inch) Accuracy is guaranteed by the totalized flow volume under the condition of continuous flow measurement for 30 seconds or longer. PHYSICAL SPECIFICATIONS Converter case finishing Standard Baked acrylic paint Corrosion-proof Baked epoxy paint Converter case material Aluminum alloy Display cover material Tempered glass Terminal box finishing (Model MTG18B only) Standard: Baked acrylic paint Corrosion-proof: Baked epoxy paint Terminal box material (Model MTG18B only) Aluminum...

Open the catalog to page 5

Right-angle joint detector Diffuser with cone angle greater than 15° (If cone angle is 15° or less, considered as straight pipe) detector Concentrator (considered as straight-pipe section) detector Cable between converter and detector (Remote type) Length 70 m (233 ft) or shorter (25 mm (1 inch) to 200 mm (8 inches)) 30 m (98 ft) or shorter (10 mm (3/8 inch), 15 mm (1/2 inch)) Outside diameter 11.4 mm (0.45 inch) Maximum cable length of SMC11 cable Gate Value detector (completely open) Any Control Value detector Size 10mm, 15mm Size 25mm or larger Any pump 70m Figure 2 Maximum...

Open the catalog to page 6

Notice for installation To fully enjoy the performance of the device, please choose an appropriate location according to the following. Notice after installation A WARNING When removing the device from the piping, make sure that there is no line pressure or process fluid inside of the device. Removing the device before depressurizing may result in serious injury. A CAUTION Do not use the device as a foothold. It may cause injury or damage of the device. Notice for environment • Install the flowmeter in a location with an ambient temperature of -25°C to 60°C (-13°F to 140°F) and an ambient...

Open the catalog to page 7

tions. Those fluid may cause of inaccurate flow measurement. • Fluids that have sufficient conductivity at high temperature but do not meet the conductivity requirement at room temperature (about 20°C (68°F)). (e.g. fatty acids and soap) • Some fluids contain surfactant (e.g. rinse, shampoo and CWM (coal water mixture)) • Insulating adhesive materials (e.g. kaolinite, kaolin, calcium stearate) • The analog output may fluctuate due to flow noise, which is generated by the process fluid flow. In such a case, connect the upstream grounding ring to the downstream grounding ring by a wire. The...

Open the catalog to page 8All Azbil North America catalogs and technical brochures

-

NX-D25

2 Pages

-

NX-CB2

1 Pages

-

NX-CL1/CL2/TL1/TR1

1 Pages

-

RN748A

1 Pages

-

HM

1 Pages

-

ECM3000 Control Motor

8 Pages

-

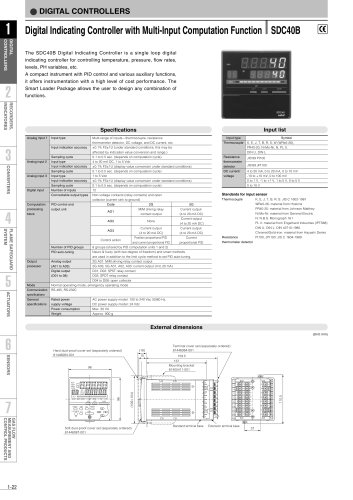

Multi-Loop Controller SDC46A

2 Pages

-

Single Loop Controller SDC25

2 Pages

-

Single Loop Controller SDC15

2 Pages

-

YYU4 Simple Thermocouple

1 Pages

-

Fiber Units HPF Series

26 Pages

-

FL2 Series

6 Pages

-

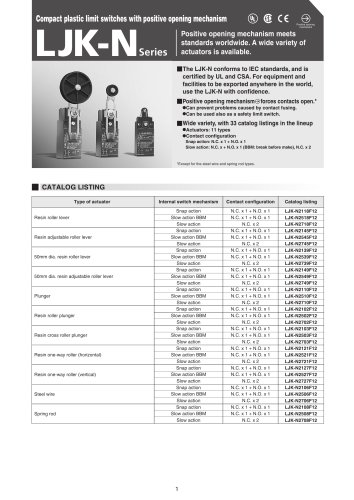

LJM-D series

4 Pages

-

BZ Series Basic Switch

9 Pages

-

CMG Series Gas Flow Monitor

4 Pages

-

MCF Series Air Flow Meter

2 Pages

-

MAGNEW Series

3 Pages

-

HP100

10 Pages

-

HPX

10 Pages

-

HPX-AG

20 Pages

-

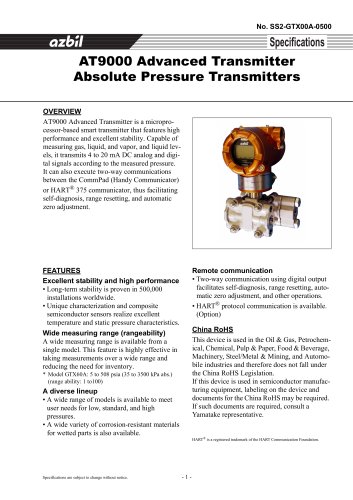

APT

2 Pages

-

APM

6 Pages

-

FL7M

10 Pages

-

ATT70

8 Pages

-

WaterMAG

8 Pages

Archived catalogs

-

MagneW 3000 Plus CA2-MGG-01

4 Pages

-

MagneW 3000 PLUS HENRI

2 Pages

-

MagneW Two-Wire Plus

20 Pages