Website:

Azbil Europe NV

Website:

Azbil Europe NV

Group: azbil

Catalog excerpts

High-Accuracy Position Sensors K1G Series Scheduled release: August 2014 Note: Release date, specifications, and model No. are subject to change without prior notice. Please contact our sales staff for details.

Open the catalog to page 1

New High-Performance Laser Sensors Performance and functions far exceed conventional norms, allowing you to make the measurements you want. A combination of a CMOS linear image sensor and collimated lasers ensures high-accuracy workpiece position measurement. See what you previously couldn’t. >> 03 Minute variations not visible with conventional sensors can now be reliably detected.

Open the catalog to page 2

Easily mounts anywhere. Compact dimensions are achieved by slim sensor head design. Less wasted time. Comes with a full range of functions to help cut job time for design, installation, and maintenance.

Open the catalog to page 3

See what you previously couldn’t. Tiny variations and high-speed fluctuations overlooked by conventional sensors can now be reliably detected and visualized by the K1G series. Resolution: 0.1 µm Measurement period: 250 µs

Open the catalog to page 4

In-line inspection of glass edges Up until now glass edges and surfaces were checked offline by operators for defects such as chips. The K1G series, however, makes high-speed in-line measurements with a high degree of accuracy. This means that fast, highly accurate glass measurements can now be made regardless of how the edge surface is processed. Edge measurement (artist’s conception) 0.1 µm resolution —the highest level in its class! Fresnel diffraction Azbil’s unique FDN algorithm, which utilizes Fresnel diffraction phenomena and sophisticated high resolution technologies, has achieved...

Open the catalog to page 5

Have you encountered “doesn’t fit” or “can’t measure” problems due to sensor size? K1G series designers made ultra-slimness a high priority.

Open the catalog to page 6

Conventional size Wafer alignment in IC manufacturing Facilitates miniaturization A small sensor head allows a small alignment unit, helping to reduce the overall equipment footprint. Wafer alignment (artist’s conception) Panel-mount multi-channel controller A single controller can connect to as many as four sensor heads. Two types of sensor head can be used together. Ultra-thin sensor head Meticulous efforts have produced an ultra-thin head in all its dimensions. Two sensor models, having detection ranges of 7 mm and 15 mm, are available and are ideal for a wide diversity of applications....

Open the catalog to page 7

Less wasted time. The K1G series is equipped with a host of functions to fully streamline your work time before and after measurement. Built-in wiring check function K1G series controllers include a test mode to allow you to freely switch between analog and digital output, so that connections can be checked before the start of equipment operation. Built-in multi-calculation functions Multi-channel controllers help calculate data between channels. This cuts the time needed to write programs for host computing equipment and enables easy measurement of thicknesses and widths. Output of...

Open the catalog to page 8

Enhanced light-axis adjustment function Preventive maintenance functions The light-axis alignment function is now highly advanced compared to ordinary models. A light-axis alignment indicator mounted on the sensor head greatly cuts the time needed for alignment. The K1G series is equipped with functions for detecting foreign matter on the sensor heads and deviation of the sensor head optical axis. These functions prevent problems during operation and reduce unneeded servicing work. Sensor installation Equipment startup and operation Special setup tool collects measured data Measurement data...

Open the catalog to page 9

Stepping up to a new level of measurement Tablet (made by Yaskawa Electric Corporation) Ethernet Wi-Fi Display unit GP4000 High-Accuracy Position Sensors K1G-C04M (made by Yaskawa Electric Corporation) Multi-channel controller supports the Mechatrolink-III open field network. This allows the transfer of measurement data over communication networks and will open up a host of new applications and advantages. 09-10

Open the catalog to page 10

Small footprint and less wiring High-speed communications to a maximum of 100 Mbps and highreliability protocols allow the transfer of measurement data over communication networks. Since input and output require only two wires, the number of wires and space for installation can be greatly reduced. Conventional wiring Synchronization between channels To guarantee data synchronization, Mechatrolink-III allows easy extraction of synchronized data from all devices on the network. This, for example, allows checking of operations after tooling changes and efficient pinpointing of any trouble that...

Open the catalog to page 11

Typical applications ■ Film meander measurement By using both of the sensor head channels, the controller’s calculation function can simultaneously measure film meander and film width. Highly transparent glass or gallium arsenic wafers can be reliably measured with a high degree of accuracy. 450 mm wafer notches can also be measured with good reliability at a measuring cycle of 250 µs. ■ Film sheet thickness measurement ■ Measurement of gap between rollers ■ Detection of intermixed electronic components At a resolution of 0.1 µm, measurements can be made with a high degree of accuracy. A...

Open the catalog to page 12

Sensor heads Controllers Catalog listing *1. Accuracy specifications are for 23±2 °C under the conditions below.

Open the catalog to page 13

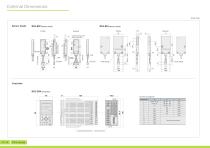

Sensor heads K1G-S07 (Sensor heads) K1G-S15 Sensor heads) K1G-C04 (Controller) Terminal arrangement

Open the catalog to page 14

Sensors K1G-S07 | Measurement Width 7 mm K1G-S15 | Measurement Width 15 mm Controllers K1G-C04 | 4-channel controller Other product names, model numbers and company names may be trademarks of the respective company. [Notice] Specifications are subject to change without notice. No part of this publication may be reproduced or duplicated without the prior written permission of Azbil Corporation. Azbil Corporation Advanced Automation Company Yamatake Corporation changed its name to Azbil Corporation on April 1,2012. 1-12-2 Kawana, Fujisawa Kanagawa 251-8522 Japan URL:...

Open the catalog to page 16All Azbil Europe NV catalogs and technical brochures

-

V8C/V8S

4 Pages

-

F4Q

6 Pages

-

F7M

4 Pages

-

Air purge control

2 Pages

-

Liquid temperature control

2 Pages

-

Wafer detection sensor

2 Pages

-

Wafer alignment sensor

2 Pages

-

Liquid level sensors

2 Pages

-

Liquid leakage sensors

2 Pages

-

Paperless Recorder ARF

7 Pages

-

Fiber Unit Selection Guide HPF

26 Pages

-

Gas Mass Flowmeter CMS

4 Pages

-

Air Flow Meter MCF

8 Pages

-

WET process sensors

16 Pages

-

AT9000

2 Pages

-

Digital Mass Flow Controller

6 Pages

-

HP series

16 Pages

-

Capacitance Diaphragm Gauge

4 Pages

-

Meets Global Standards

12 Pages

-

AX Series Vortex Meters

12 Pages

-

GasCVD

2 Pages

-

MagneW 3000 PLUS+

2 Pages

-

MagneW NeoPLUS

2 Pages

-

Single Loop Controller SDC15

2 Pages

-

Azbil Group introduction

8 Pages