Website:

AZ spa

Website:

AZ spa

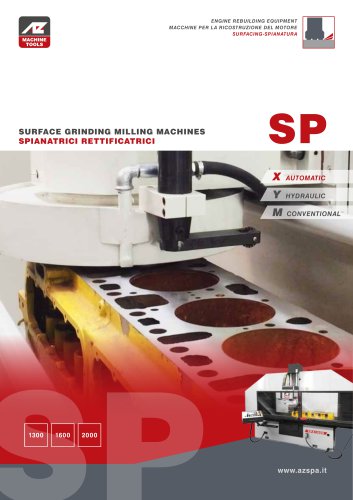

Catalog excerpts

C RA N K S H A FT & CA MS H A FT GR IN D IN G M ACHI NES R E TTIFICATR IC I P E R A LB E R I A GOMITO E CAM M E

Open the catalog to page 1

GRINDING TECHNOLOGY EXCELLENCE FOR AUTOMOTIVE I N D U S T RY L’ E C C E L L E N Z A N E L L A R E T T I F I C A A S E R V I Z I O D E L L’ I N D U S T R I A AUTOMOTIV

Open the catalog to page 3

The movements, fully CNC controlled, are made by closed-loop linear motors control with external high precison linear scale. Base in composite material of concrete and steel, specifically designed to obtain the best result between structural deformations and natural frequencies allowed. I movimenti della macchina sono controllati dal controllo numerico e realizzati da un motore lineare, controllato mediante encoder lineare esterno a ciclo chiuso ad alta precisione. Basamento in materiale composito di calcestruzzo e acciaio, studiato appositamente per ottenere il miglior risultato tra...

Open the catalog to page 4

Height of centers Swing over table Max length of grinding Altezza centri Swing Max lunghezza di rettifica Max diameter of CBN grinding wheel [mm] from 610 to 965 Diametro massimo della mola in CBN Max diameter of corundum grinding wheel [mm] from 760 to 1066 Diametro massimo della mola in corindone Grinding wheel width range [mm] from 10^50 to 35^140 Larghezza della mola Max weight between centers [kg] from 80 to 1500 Peso massimo ammesso tra i centri Min distance between centers [mm] from 30 to 150 Distanza minima tra i centri Max distance between...

Open the catalog to page 5

HEADSTOCK & TAILSTOCK FANTINA E CONTROPUNTA PAG The headstock and tailstock are divided in two parts this allows micrometre roundness between the centers. On the headstock spindle can be installed an auto-clamping and auto-compensating hydraulic three jaws chuck system. Hydraulic automatic steady rests allow to support the workpiece on the main pins selected during processing. I corpi della fantina e della contropunta sono divisi in due parti questo consente la regolazione micrometrica della cilindricità tra le punte. Sul mandrino portapezzo può essere installato un sistema di bloccaggio a...

Open the catalog to page 6

GRINDING WHEEL HEAD TESTA PORTAMOLA The movements of the grinding head are made by linear motors. The position of these is continuously monitored by closed loop absolute linear encoders. The dynamic grinding wheel balancing is ensured by an internal dynamic balancer with gap and crush control sensor. The machine is equipped with vitrified CBN grinding wheels, recommended for high production. The automatic cycle of shaping and dressing of the grinding wheels is made by one or two electric spindles with rollers diamond dresser. I movimenti della testa portamola avvengono tramite motori...

Open the catalog to page 8

MEASUREMENT & CONTROL SISTEMA DI MISURAZIONE E CONTROLLO IN-PROCESS MEASUREMENT SYSTEM: has the ability to measure following the orbital movement of the machining providing continuously reading of ovalization of the pins. GAP CONTROL SYSTEM SHAPE CONTROL SYSTEM DRESSING CONTROL SYSTEM CRASH CONTROL SYSTEM MISURATORE IN CONTINUO: questo strumento ha la possibilità di misurare in continuo e durante il processo, seguendo il movimento orbitale della lavorazione e fornendo la lettura dell’ovalizzazione del perno in lavorazione. TASTATORE PER POSIZIONAMENTO CONTROLLO FINE TAGLIO IN ARIA CONTROLLO...

Open the catalog to page 10

NEW ADVANCED MEASURING SYSTEMS FOR QUALITY ASSURANCE OF GRINDED PARTS NUOVO SISTEMA DI MISURAZIONE DELLA QUALITÀ DI RETTIFICA DI PARTI CILINDRICHE PAG 12 For statistical process control (SPC), allow extremely efficient monitoring of the manufacturing process and rapid intervention where necessary. We can produce grinded parts of a consistently high quality. Macchina per il controllo statistico di processo (SPC), permette il monitoraggio del processo di rettifica del pezzo ed eventual correzioni su questo dove necessario. In questo modo possiamo rettificare pezzi di alta qualità e precisione.

Open the catalog to page 12

ROBOTICS / ROBOTICA The machine can be equipped with Anthropomorphic or Cartesian robot for loading and unloading of workpiece. Advanced courses for technicians and schools: operation and management, CNC programming, maintenance. La macchina può essere dotata di robot antropomorfo o cartesiano per carico e scarico del pezzo. Corsi avanzati per tecnici e scuole: utilizzo e gestione della macchina, porgrammazione CNC, manutenzione.

Open the catalog to page 14

MONITORING SYSTEM / SISTEMA DI MONITORAGGIO Monitoring system to control remotely some CNC machine parameters. Equipped with live video streaming solution built-in to monitor what the machine is doing in real time through a camera inside the working area and joystick on the control panel. Sistema di monitoraggio che permette di controllare da remoto alcuni parametri del controllo numerico. E dotato di un sistema di monitoraggio in tempo reale tramite video attraverso una telecamera all’interno dell’area di lavoro e un joystick su pannello comandi. TECHNICAL ASSISTANCE / ASSISTENZA...

Open the catalog to page 15

C N C C RA N K S H A F T G R I N D I N G M AC H I N E S AZ s pa v iale dell’elett ronic a 20 36016 Thiene ( VI ) I taly www.az spa.it _MADE IN EUROPE _MADE IN ITALY _MADE IN VENETO Marketing Dept. of AZ spa EN/IT - 20180821 AZ Copyright © 2018 No part of this document may be reproduced, copied, adapted, or transmitted in any form or by any means without express written permission from AZ spa.The informations given is based on the technical levels of our machines at the time of this brochure going to print. We reserve the right to further develop our machines technically and make name,...

Open the catalog to page 16All AZ spa catalogs and technical brochures

-

RU Universal Grinding Machines

16 Pages

-

VG - VALVE GRINDING MACHINE

8 Pages

-

BAC Line Boring machines

8 Pages

-

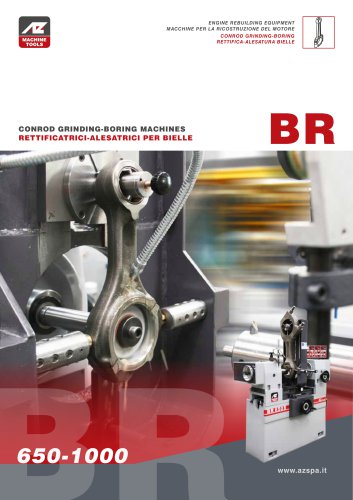

CONROD BORING-GRINDING MACHINES

16 Pages

-

RUA Universal Grinder

16 Pages

-

RUX CNC Universal grinders

14 Pages

-

CH150 Honing machine

8 Pages

-

Crankshaft grinding machines

24 Pages

-

AZ AEROSPACE

24 Pages

-

AZ Company profile

20 Pages

-

CW400

2 Pages

-

CD Magnetoscope

4 Pages

-

BL600 Conrod Boring machine

2 Pages

![CG4100 Crankshaft Grinding Machines]](https://img.directindustry.com/pdf/repository_di/51483/cg4100-crankshaft-grinding-machines-171537_1mg.jpg)