Website:

AZ spa

Website:

AZ spa

Catalog excerpts

CRANKSHAFT GRINDING MACHINES

Open the catalog to page 1

40 years of experience in Crankshaft Grinding Machines. The most complete range from 1.5 meters to 14 meters crankshaft length AZ is the world leader in the production of crankshaft grinding machines for energy, marine, railways and automotive. A qualified team of engineers, with experience in the mechanical and mechatronics engineering, and demands of the different markets, has enabled AZ grow beyond the traditional production, hydraulic and CNC controlled grinding machines for large dimensions crankshafts. AZ has installations in more than 80 countries. By careful design of this...

Open the catalog to page 2

MANUAL VERSION MOVING TABLE Distance between centers 4100 mm MOVING TABLE Distance between centers 3000-5000 mm MOVING TABLE Distance between centers 5400-6400 mm

Open the catalog to page 3

CRANKSHAFTS GRINDING MACHINES Base and Table The base is made of high resistance monolithic cast iron, thermically stabilized, it has one flat and one “V” guide. The table is a strong structure, thermically stabilized with scraped surface in order to secure the highest precision of linearity and flatness in the different positions of the workheads. The guideways are covered with special anti-friction plastic material in order to: • reduce the disengaging friction • reduce the coefficient of general friction • reduce the rubbing wear table movement with synchronous servomotor and rack...

Open the catalog to page 4

Grinding Wheel Head It moves on wide prismatic guideways. The grinding wheel spindle rotates by means of a whe-elhead spindle with high precision pre-loaded bearings. The transmission of the motion to the spindle takes places by high power V belt. X and Z axis movement is made by hydraulic piston and it moves on wide prismatic guide ways. Set-up and Clamping system The centring of the crankshaft is obtained by means of a special support equipped with three movements that allow solving precisely and easily any problem regarding the work-piece centring: • One offset movement on guides • One...

Open the catalog to page 5

CRANKSHAFTS GRINDING MACHINES STANDARD EQUIPMENT * *depends on the workpiece and customer request Heads movement on air cushion Hydraulic system and coolant system Centralized automatic lubricant system Crankshaft centering fixture with dial indicator Crankshaft journal checking square Head offset measuring device with indicator Wheel face, side and radius dresser Template for levelling the machine Motor pulley for reduced grinding wheel Chuck with diameter on request Steady rests: Heavy Steady rest Light steady rest (35kg) Steady rest for big diameter + other steady rests capacity on...

Open the catalog to page 6

OTHER EQUIPMENT* *depends on the workpiece and customer request Motorized and synchronized rotation of both workheads Electronic variable speed of the heads Siemens CNC control system and Siemens drives PLC control system Diamond and taper rest 1,5 kt Pair of flanges Continuous journal sizing gauge with forks 2 axes digital readout (x e z) Magnetic coolant cleaner Paper roll coolant cleaner Combined paper roll and magnetic coolant cleaner Grinding wheel balancing stand for static balancing Portable belt superfinisher Wheel side tapering dresser Hydraulic wheel dresser CNC Wheel dresser...

Open the catalog to page 7

Max distance between centers mm 4100 4100 4000 5000 5400 6400 Swing over table mm 920 1200 1200 1200 1300 1300 Max diameter admitted on std steady rests mm 250 250 250 250 250 250 Max workpiece diameter-new wheel mm 450 450 450 450 450 450 Max weight admitted between centers kg 1500 1500 3000 3000 3500 3500 Max weight admitted with steady rests mm 2500 2500 5000 5000 7500 7500 MACHINE SPECIFICATIONS1 Z AXIS Max table...

Open the catalog to page 8All AZ spa catalogs and technical brochures

-

RU Universal Grinding Machines

16 Pages

-

VG - VALVE GRINDING MACHINE

8 Pages

-

BAC Line Boring machines

8 Pages

-

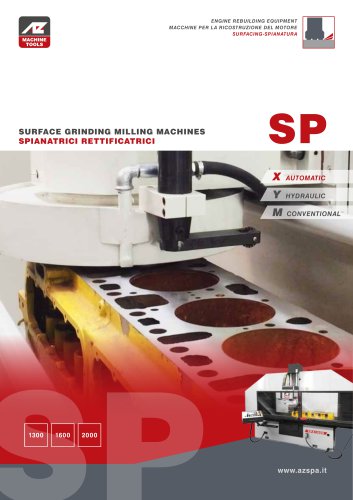

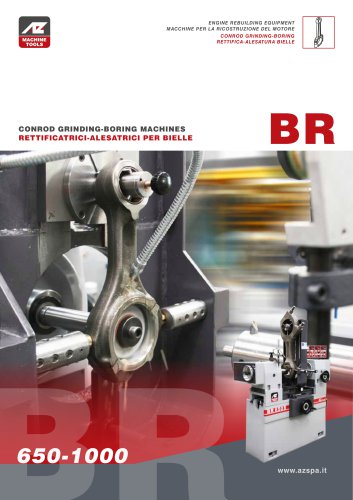

CONROD BORING-GRINDING MACHINES

16 Pages

-

RUA Universal Grinder

16 Pages

-

RUX CNC Universal grinders

14 Pages

-

CH150 Honing machine

8 Pages

-

Crankshaft grinding machines

24 Pages

-

AZ AEROSPACE

24 Pages

-

AZ Company profile

20 Pages

-

CW400

2 Pages

-

CD Magnetoscope

4 Pages

-

BL600 Conrod Boring machine

2 Pages

![CG4100 Crankshaft Grinding Machines]](https://img.directindustry.com/pdf/repository_di/51483/cg4100-crankshaft-grinding-machines-171537_1mg.jpg)