Catalog excerpts

Mass Flow Devices Success Story: GE Healthcare GE Healthcare uses Axetris Mass Flow Meters as calibration standard Highest accuracy level for calibrating respiratory modules GE Healthcare—a leading global medical technology and life sciences company—uses Axetris mass flow meters in the final flow measurement test for respiratory modules. The respiratory modules are a critical part of patient monitors used in life-critical situations in operating rooms worldwide. Axetris mass flow meters are based on MEMS thermal mass flow technology, which enables highest accuracy, eliminates sensor drift and has an extremely small pressure drop. Respiratory modules for comprehensive patient monitoring GE Healthcare’s innovative respiratory modules support procedures in the operating room by providing essential data on inhaled and exhaled CO₂, O₂, N₂O, as well as anesthesia gases. The critical gases are measured using the sidestream method, whereby gas sensors rely on an integrated flow measurement sensor to provide a complete picture during medical procedures. Axetris mass flow meter as a calibration standard The integrated flow measurement sensors in GE Healthcare’s respiratory modules undergo a rigorous calibration procedure. The final test of these flow sensors relies on the National Institute of Standards and Technology (NIST), traceable calibration on the Axetris mass flow meters. Axetris mass flow meters themselves undergo an extremely detailed calibration at the Axetris facility in Central Switzerland. The mass flow meters are calibrated in a multi-stage process, which includes complete temperature compensation of the sensor output. The inhouse MEMS thermal mass flow sensor combined with intelligent engineering also means that long-term drift of the mass flow meter is virtually negligible, making it a superior calibration standard. Accuracy and Low Pressure Drop The Axetris mass flow meter provides the required accuracy in flow measurement during production of respiratory modules used in life-critical medical procedures. “We replaced the old flow meters with Axetris mass flow meters because of the high accuracy combined with good linearity and long-term stability. The mass flow meters are ‘invisible’ in the gas flow path, due to their low pressure drop.” Hannu K. S. Engineering Manager—Gas Sensors GE Healthcare that pressure effects are completely eliminated during the final test. All these features enable GE Healthcare‘s respiratory modules to achieve the highest performance standard in gas flow control, and eventually, in patient monitoring. Besides the high level of accuracy, the extremely low pressure drop of the Axetris mass flow meters means

Open the catalog to page 1

Mass Flow Devices Success Story: GE Healthcare Performance benefits at a glance: Accuracy Dynamic Range typically for Mass Flow Meters Strict Calibration NIST Traceable Real Gas Procedure Calibration, full temperature compensation Reaction Time < 4 ms (mass flow sensor) Low Pressure Drop As low as 35 Pa (at 50 sccm flow) The Axetris Mass Flow Technology uses the proprietary platinum based MEMS chip technology. The chip consists of a heating element and two highly sensitive temperature sensors. About Axetris Mass Flow Meters and Controllers Axetris offers OEM mass flow meters (MFM) and...

Open the catalog to page 2All Axetris AG catalogs and technical brochures

-

Infrared Sources

12 Pages

-

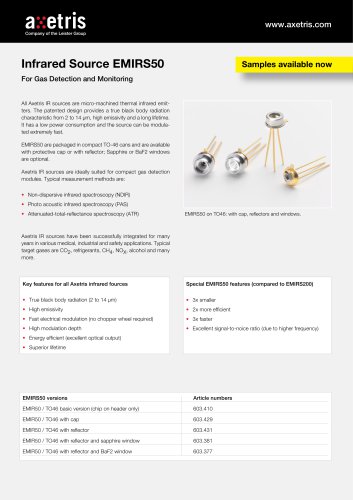

Infrared Sources EMIRS200

1 Pages

-

EMIRS200

2 Pages

-

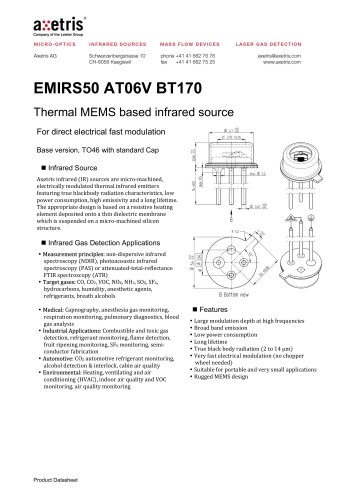

EMIRS50 AT06V BT170

8 Pages

-

EMIRS50 AT06V BR26M

8 Pages

-

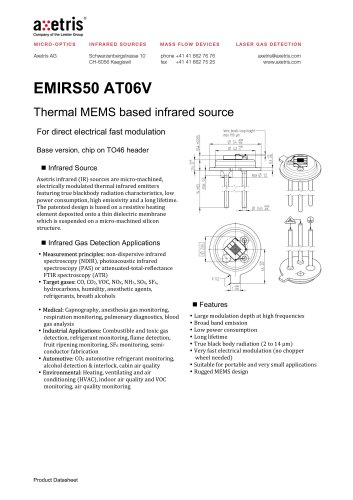

EMIRS50 AT06V

8 Pages

-

EMIRS50 AT06V BR25M

8 Pages

-

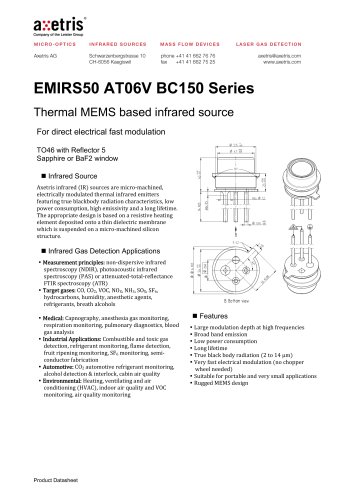

EMIRS50 AT06V BC150

8 Pages

-

MFD BaseFlo Line

2 Pages

-

EMIRS50 AT06V BC150 Series

8 Pages

-

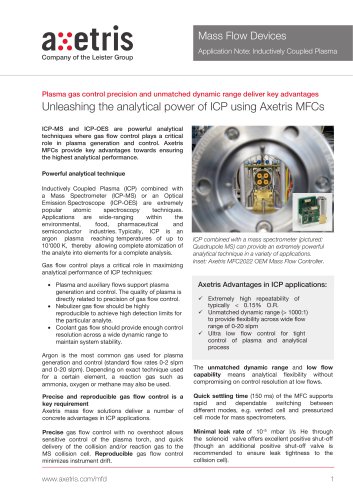

Inductively Coupled Plasma

2 Pages

-

Gas Chromatography

2 Pages

-

MFM / MFC RS-232

24 Pages

-

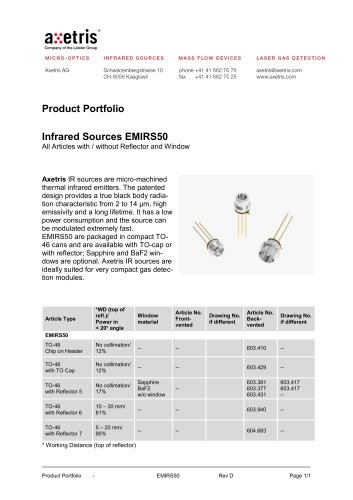

Infrared Sources EMIRS50

1 Pages

-

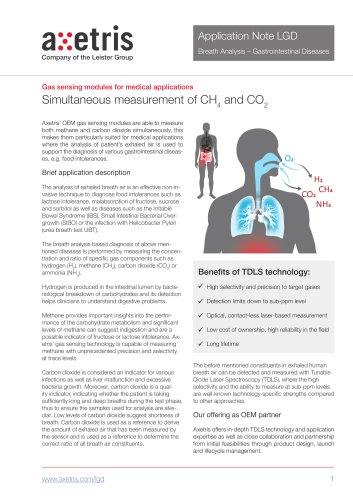

LGDF200 A CH4

8 Pages

-

LGDF200 H HCl

9 Pages

-

FL - Infrared Source EMIRS50

2 Pages

-

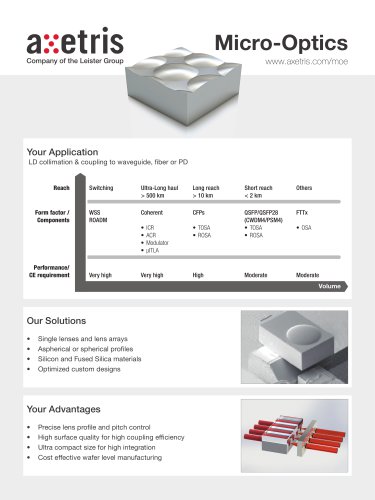

Micro-Optics

2 Pages

-

Infrared Sources EMIRS200

12 Pages

-

DS - LGDF200 H NH3

9 Pages

-

DS- LGDF200 A NH3

8 Pages

-

DS - LGDF200 A CO2

8 Pages

-

FL - Axetris MFD Plus

2 Pages

-

FL - LGD F200P2

2 Pages

-

Reflector

4 Pages

-

MEMS Services

2 Pages