Catalog excerpts

Product Datasheet Mass Flow Controller modules MFC 2000 and MFC 2200 Series High Performance Gas Flow Control for OEMs Figure 1 Axetris offers a wide range of mass flow controller modules based on its in-house platinum-based MEMS technology for outstanding mass flow performance. The MFC 2000 series comes with a variety of options for mechanical and electronical interfaces, and are tailored to the needs of its OEM customers. Axetris offers OEM Mass Flow Controller Modules (MFC) for gases with outstanding value to the customer. The Platinum based MEMS chip technology guarantees excellent stability and repeatability over the whole flow range. The high speed of the MEMS technology combined with smart software processing and the fast acting valve, allows any easy and stable control of the gas stream even in the most demanding applications. Due to the unmatched dynamic range and the multi gas capability, Axetris MFC 2000 and MFC 2200 modules can replace several conventional mass flow controllers with a single unit. The compact and robust design makes it also an ideal choice for portable applications. All MFC 2000 and 2200 modules support digital communication for configuration, to read flow values, for set point adjustment, and for gas curve selection. 01.03.17 Rev.E The Axetris mass flow technology is already used by many major companies in the field of Gas Chromatography, Leak testing, Thermal Analytics, Mass Spectroscopy, Thin Film Deposition, Plasma Engineering and more. Platinum-based MEMS technology High accuracy and stability Unmatched dynamic range Excellent zero point stability Ultra-fast response time and settling time Excellent repeatability and reproducibility Ultra-compact size Robust packaging with metal flow channel Flow range zooming (optional)

Open the catalog to page 1

Figure 2 The Axetris platinum-based MEMS chip guarantees excellent stability, repeatability and quick response time over the complete flow range Exceptional long term stability Digitally calibrated Full temperature compensation (0 to 50°C) Multi-gas/range capability, up to 8 calibration curves Anemometric measurement principle High Precision PID controller Various digital and analog I/O supported Rigid stable design Various optional flow interfaces RoHS 2011/65/EU compliant NIST traceable calibration Gas chromatography Thermal analysis Mass spectroscopy Leak testing Thin-Film process...

Open the catalog to page 2

2 Type Overview The MFC 2000 and 2200 series of mass flow controllers is available with four different electronic interfaces (Table 1.) The MFC 2022 is the most economical solution and is recommended for direct connection to a microprocessor with typical wiring lengths below 30 cm. For medium line distances the MFC 2222 is recommended and if several devices need to be addressed on a single line the MFC 2242 or MFC 2252 is the best choice. These types support also the longest connection length because of the differential mode offered by RS 485. Type Analog Digital Recommended...

Open the catalog to page 3

3 Block Diagram – Mass Flow Regulation PID_out (Analog) Set point (Analog/Digital) Valve override (Analog/Digital) Data & command (Digital I/O) uP T Compensation Linearization EEPROM Parameters Calibration Data Valve Driver Sensor Chip Gas flow meter (Analog/Digital) Heater regulation Figure 3 Block diagram of the MFC 2000 and MFC 2200 mass flow controller module series The analog input/output is available for all models, except those with RS485 interface

Open the catalog to page 4

- • ® axetris Company of the Leister Group 4 Hardware and Flow Performance specifications Note: The specification defines typical values for MFCs calibrated with Nitrogen (N2) without connection blocks. Optimal digital noise filter (k-factor) settings are assumed. For specific questions, e.g. other gases and conditions or higher accuracy, contact Axetris. Test Conditions: Temperature 25 °C, input pressure Pin 4 bara (absolute), outlet: atmospheric pressure, vertical mounting position, digital output. Standard full scales available with N2 calibration; For other full scales, please contact...

Open the catalog to page 5

4.2 Environmental conditions Parameter Unit Value / Range Operating temperature Humidity Storage temperature 4.3 Electrical characteristics Parameter Unit Value / Range Voltage supply DC Nominal Ripple Current supply DC, typical Max. current supply DC Start-up time Warm-up time Deviation < ±0.1% F.S. For optimum accuracy Analog output Resistive loads Capacitive loads Overload protection Valve override, set point input gas flow output PID output_ DC protected up to supply voltage / ESD protected ESD protected ESD protected (output available on MFC 2022 only)

Open the catalog to page 6

4.4 Communication Interface Parameter Unit Value / Range RS-232 TTL RS-232 EIA RS-485 half duplex _RS-485 full duplex_ dig. 0...65535 - Specified protocol dig. 1% F.S. (active on request at factory level) Communication interface hardware MFC 2022 MFC 2222 MFC 2242 MFC 2252_ Digital Input Set point Valve override1 2 3 Channel selection 3 External offset zeroing Cut off limit_ Digital Output Gas flow Temperature4 Device number_ For MFC 2022 and MFC 2222 only Analog Input5 Set point Valve override Cut off limit_ Analog Output Gas flow PID Out - serial number V 0 / 5 (close /...

Open the catalog to page 7

5 User interface pin assignment MFC 2022 Table 2 Pin assignment MFC 2022, connector type JST-SM09B-SR MFC 2222, MFC 2242, MfC 2252, connector type Micromatch 8-pole

Open the catalog to page 8

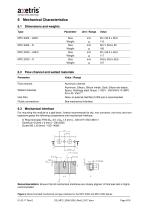

- • ® axetris Company of the Leister Group 6 Mechanical Characteristics Flow channel Wetted materials Inlet filter Fluidic connections Value / Range Aluminum channel Aluminum, Silicon, Silicon nitride, Gold, Silicon die-attach, Epoxy, Stainless steel, Brass, 1.4301 - X5CrNi18-10 (MFC 2xxx-D), VitonTM None, an external inlet filter (5-200 pm) is recommended See mechanical interface 6.3 Mechanical interface For mounting the module to a gas block, Axetris recommends for dry, non-corrosive, non-toxic and nonexplosive gases the following components and mechanical interface: - O-Ring Normatec FKM...

Open the catalog to page 9

- • ® axetris Company of the Leister Group A number of standard flow connection blocks (with sideports or downports) are available with Axetris. These flow connection blocks are supplied mounted and leak tested with the mass flow device. The flow connection blocks are compatible with standard fluidic connectors (e.g. from Swagelok™). The main flow connection blocks are listed here - for a complete list, discuss your exact requirements with your Axetris sales contact:

Open the catalog to page 10All Axetris AG catalogs and technical brochures

-

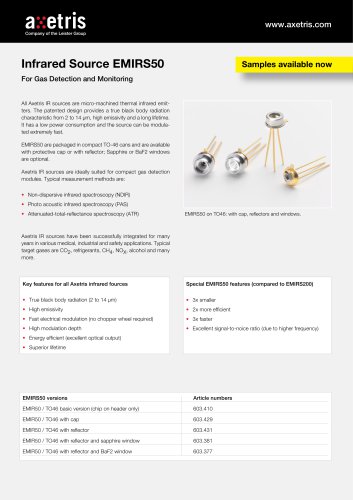

Infrared Sources

12 Pages

-

Infrared Sources EMIRS200

1 Pages

-

EMIRS200

2 Pages

-

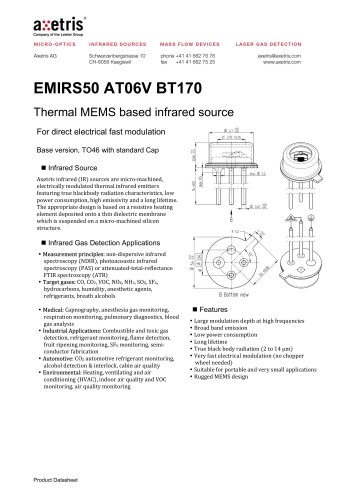

EMIRS50 AT06V BT170

8 Pages

-

EMIRS50 AT06V BR26M

8 Pages

-

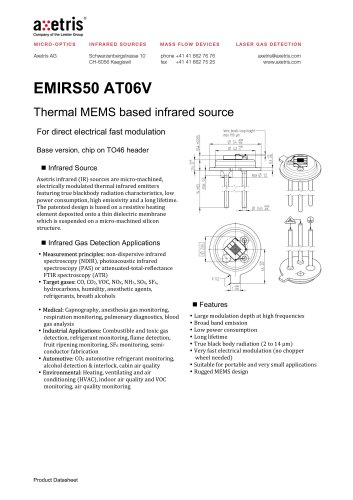

EMIRS50 AT06V

8 Pages

-

EMIRS50 AT06V BR25M

8 Pages

-

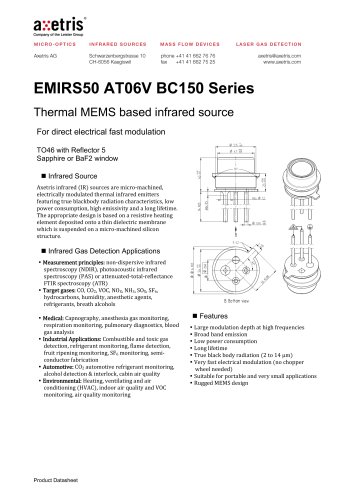

EMIRS50 AT06V BC150

8 Pages

-

MFD BaseFlo Line

2 Pages

-

EMIRS50 AT06V BC150 Series

8 Pages

-

Inductively Coupled Plasma

2 Pages

-

Gas Chromatography

2 Pages

-

MFM / MFC RS-232

24 Pages

-

Infrared Sources EMIRS50

1 Pages

-

LGDF200 A CH4

8 Pages

-

LGDF200 H HCl

9 Pages

-

FL - Infrared Source EMIRS50

2 Pages

-

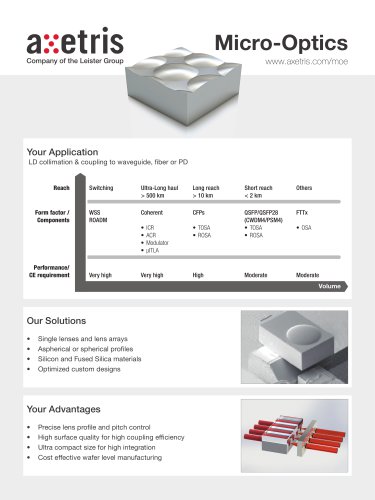

Micro-Optics

2 Pages

-

Infrared Sources EMIRS200

12 Pages

-

DS - LGDF200 H NH3

9 Pages

-

DS- LGDF200 A NH3

8 Pages

-

DS - LGDF200 A CO2

8 Pages

-

FL - Axetris MFD Plus

2 Pages

-

FL - LGD F200P2

2 Pages

-

Reflector

4 Pages

-

MEMS Services

2 Pages