Website:

Axetris AG

Website:

Axetris AG

Group: LEISTER

Catalog excerpts

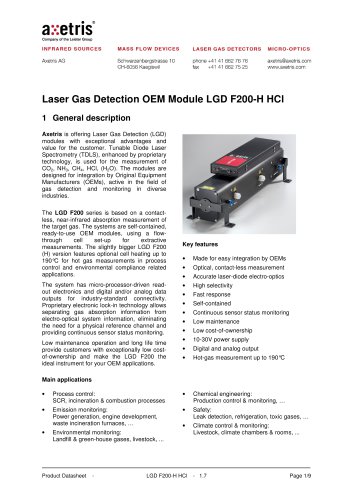

axetris* Company of the Leister Group INFRARED SOURCES MASS FLOW DEVICES LASER GAS DETECTORS MICRO-OPTICS axetris@axetris.com www.axetris.com Laser Gas Detection OEM 1 General description Axetris is offering Laser Gas Detection (LGD) modules with exceptional advantages and value for the customer. Tunable Diode Laser Spectrometry (TDLS), enhanced by proprietary technology, is used for the measurement of CO2, NH3, CH4, HCl, (H2O). The modules are designed for integration by Original Equipment Manufacturers (OEMs), active in the field of gas detection and monitoring in diverse industries. The LGD F200 series is based on a contactless, near-infrared absorption measurement of the target gas. The systems are self-contained, ready-to-use OEM modules, using a flowthrough cell set-up for extractive measurements. The slightly bigger LGD F200 (H) version features optional cell heating up to 190°C for hot gas measurements in process control and environmental compliance related applications. The system has micro-processor-driven readout electronics and digital and/or analog data outputs for industry-standard connectivity. Proprietary electronic lock-in technology allows separating gas absorption information from electro-optical system information, eliminating the need for a physical reference channel and providing continuous sensor status monitoring. Low maintenance operation and long life time provide customers with exceptionally low cost-of-ownership and make the LGD F200 the ideal instrument for your OEM applications. Main applications • Process control: SCR, incineration & combustion processes • Emission monitoring: Power generation, engine development, waste incineration furnaces, ... • Environmental monitoring: Landfill & green-house gases, livestock, ... Key features • Made for easy integration by OEMs • Optical, contact-less measurement • Accurate laser-diode electro-optics • High selectivity • Fast response • Self-contained • Continuous sensor status monitoring • Low maintenance • Low cost-of-ownership • Digital and analog output • Hot-gas measurement up to 190°C • Chemical engineering: Production control & monitoring, . • Safety: Leak detection, refrigeration, toxic gases, . • Climate control & monitoring: Livestock, climate chambers & rooms, ...

Open the catalog to page 1

axetris Company of the Leister Group 2 Hardware specifications 2.1 Gas detection specifications Important: Reference conditions: External: 20°} - 23°C, 920 -1020 hPa, 40 to 50% r.H.; Gas & cell: Incoming gas temperature at 190qC, measurement cell at 190°C, 10% absolute H2O in the measurement gas. Parameter Unit Value / Range Principle of detection - Tunable Diode Laser Spectrometry (TDLS) calibration to full scale (FS) range, standard is 50 ppm, for safety reasons max. calibration to 100 ppm (linearity up to 500 ppm, no warranty of precision) Accuracy1 - ± 2.0 % full scale...

Open the catalog to page 2

Company of the Leister Group Parameter Unit Maximum operating temperature range Operating humidity % r.H. Operating pressure mbar Storage temperature °C Parameter Unit Standard cell length mm Std. optical path length mm Standard cell volume mL Maximum measurement mL / min gas flow rate (Minimum) Dimensions housing, mm3 heated (H) version: Approx. weight, heated kg (H) version Inlet / outlet connectors, mm measurement gas Inlet / outlet connectors, mm Value / Range Value / Range Flow-through set-up 200 400 15 5’000 (1 ’500); std. calibration carried out...

Open the catalog to page 3

Parameter Unit Value / Range Digital I/O RS232 dig. Analog output Current output mA Voltage output V Protocol available On request only _ • ® axetris Company of the Leister Group 4...20, 12-bit resolution (on 0 ... 25 mA); standard 0...5, 12-bit resolution; on request upon order Customer definable 3.1 System Power / User interface connector assignments Figure 1a: Head view electronics housing. System Power / User interface terminal connector assignment. Connector assignment: Power supply 10 ... 30V Power supply ground DB 15 Connector - Housing Ground serial communication UART...

Open the catalog to page 4

Figure 1b: Cell heater screw terminal connector assignment. Head view electronics housing.Connector assignment: Pin Name Description Product Datasheet

Open the catalog to page 5

Figure 3: Side view, with gas connectors. Dimensions in mm. Figure 4: Front view. Dimensions in mm. Product Datasheet

Open the catalog to page 6

Figure 5: Top view. Dimensions in mm. 5 Mechanical interface The module is equipped at its front & back end with mounting brackets. The brackets can be fixed in four different 90° rotated positions. To increase vibration and shock protection Axetris provides rubber fixations that can me mounted between the brackets and the instrument mounting location. 6 Gas Conditioning and filtering Due to the multitude of applications for the LGD, gas conditioning and filtering has to be carried out by the integrating Original Equipment Manufacturer (OEM). The following points are crucial in order to...

Open the catalog to page 7

_ • ® axetris Company of the Leister Group 7 Certifications Type Standard / Limits Regulation European Conformity: CE Safety of laboratory EN/IEC 61010 products Safety of laser products EN/IEC 60825-1 EMC EN/IEC 61326-1 EMC: Electrical equipment for measurement, Immunity control and laboratory use H-version: Basic requirements ( 3V/m) Shock EN60068-2-27 50 m/s2, 50ms, half sinus, Crossover frequency 25Hz, 1 octave /min, 2h per orientation (total 20 Frequency cycle) Electronics conformity RoHS / WEEE Product Datasheet

Open the catalog to page 8

Company of the Leister Group 8 Factory calibration The LGD F200 are factory calibrated to customer specifications. In some cases a more specific customer calibration might be needed where complicated measurement conditions or complex gas matrices are present. In this case the customer might proceed to perform his own calibration of the system. Systematic differences between the factory calibration set-up and the customer measurement/calibration set-up can be handled with an off-set and gain adjustment of the sensor. 9 Installation instructions Questions related to the user interface,...

Open the catalog to page 9All Axetris AG catalogs and technical brochures

-

EMIRS50 AT06V BT170

8 Pages

-

EMIRS50 AT06V BR26M

8 Pages

-

EMIRS50 AT06V

8 Pages

-

EMIRS50 AT06V BR25M

8 Pages

-

EMIRS50 AT06V BC150

8 Pages

-

MFD BaseFlo Line

2 Pages

-

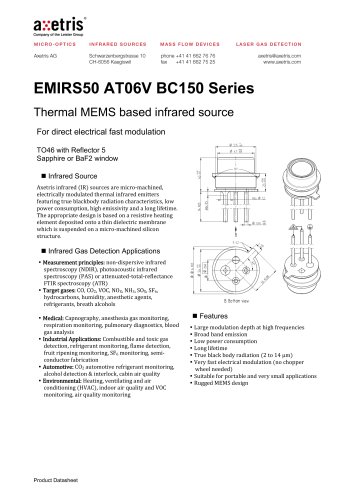

EMIRS50 AT06V BC150 Series

8 Pages

-

Inductively Coupled Plasma

2 Pages

-

Gas Chromatography

2 Pages

-

MFM / MFC RS-232

24 Pages

-

Infrared Sources EMIRS50

1 Pages

-

LGDF200 A CH4

8 Pages

-

FL - Infrared Source EMIRS50

2 Pages

-

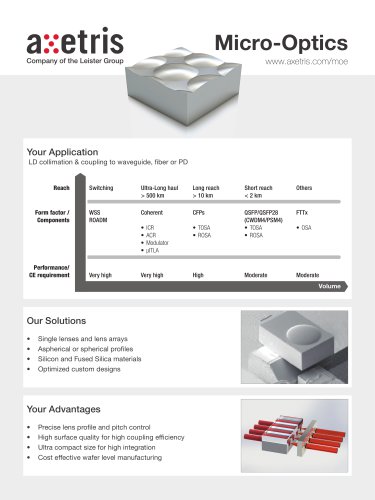

Micro-Optics

2 Pages

-

Infrared Sources EMIRS200

12 Pages

-

Infrared Sources EMIRS200

1 Pages

-

DS - LGDF200 H NH3

9 Pages

-

DS- LGDF200 A NH3

8 Pages

-

DS - LGDF200 A CO2

8 Pages

-

FL - Axetris MFD Plus

2 Pages

-

FL - LGD F200P2

2 Pages

-

Reflector

4 Pages

-

MEMS Services

2 Pages