Catalog excerpts

Application Note MFD Leak Testing High reproducibility and bidirectional flow measurement increase leak testing efficiency High-precision leak testing with Axetris mass flow meters Flow and pressure based leak testing is an integral part of the production process for a variety of industrial goods, ranging from automotive and industrial to medical parts. Axetris mass flow meters help to detect even the smallest leaks thanks to their extraordinary sensitivity, and they also help increase production efficiency due to an ultrafast response time of 4 ms. An additional asset is their capability for bidirectional flow measurement. Leak testing is a standard procedure to examine leak integrity for a variety of industrial goods, e.g. automotive parts, industrial valves and medical devices, to name a few. Among a variety of leak testing techniques available on the market, such based on flow and pressure measurement are typically used to test for leaks upwards of 0.1 sccm (standard cubic centimeters per minute). There are two ways to measure a flow. Firstly, a mass flow sensor or a mass flow meter can be used directly to measure the mass flow of gas (typically industrial air or helium) escaping due to a leak. Secondly, the measurement can be conducted indirectly by supporting fill-up of the part to be tested, and subsequently measuring the drop of pressure (pressure decay testing). Quick determination of stable conditions Since leak testing is usually part of a standard quality assurance process in production, quick leak testing cycles are essential. A mass flow sensor that possesses a quick reaction time delivers the required efficiency. Additionally, the system or unit being tested needs to reach gas equilibrium (stable conditions) before a leak test can be correctly undertaken. For a quick determination of the stable state, flow measurement in both directions is required. Leak testing is a critical step in the production of a range of industrial products, Here: production of industrial valves Axetris Advantages in Leak Testing Applications: Sensor response time of 4 ms Extremely high repeatability of typically < 0.05% O.R. Bidirectional flow measurement Low flow capability Miniscule pressure drop Why thermal mass flow measurement? The MEMS thermal mass flow measurement principle offers a variety of application specific advantages. Due to the extremely low thermal mass of the basic mass flow measurement sensor in Axetris products, an industryleading response time of 4 ms can be achieved. In addition, a very high reproducibility eliminates the need for regular calibrations and delivers accurate leak test results over long periods. Axetris mass flow meters offer an unmatched dynamic range (>1000:1), helping customers operate across a wide range of flow values and down to very low mass flow rates. A miniscule pressure drop across the mass flow sensor eliminates any added system inaccuracy.

Open the catalog to page 1

Company of the Leister Group Performance benefits at a glance: S Repeatability +/- 0.05% O.R. typically for Mass Flow Meters Available in two versions: S Bidirectional Flow • Symmetric +/-100% F.S. • Asymmetric +100%/-10% F.S. S High Accuracy +/- 0.2% F.S. / +/- 1% O.R. (Forward Direction) whichever is greater S Pressure Drop S Dimensions S Sensor Response 35 Pa@50sccm 16.4 x 34 x 48.5 mm (OEM Mass Flow Meter) < 4 ms O.R.: Of Reading; F.S.: Full Scale Typical values only, consult product datasheet for all product options About Axetris Mass Flow Meters and Controllers Axetris offers OEM mass...

Open the catalog to page 2All Axetris AG catalogs and technical brochures

-

Infrared Sources

12 Pages

-

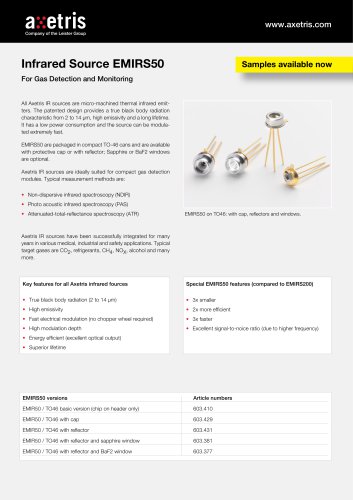

Infrared Sources EMIRS200

1 Pages

-

EMIRS200

2 Pages

-

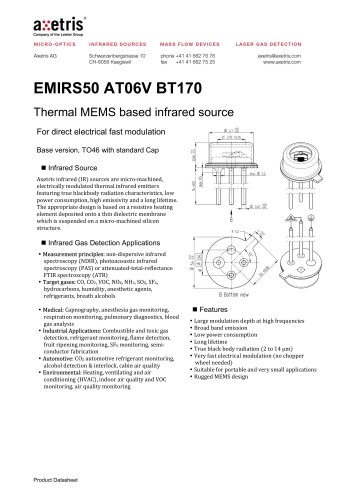

EMIRS50 AT06V BT170

8 Pages

-

EMIRS50 AT06V BR26M

8 Pages

-

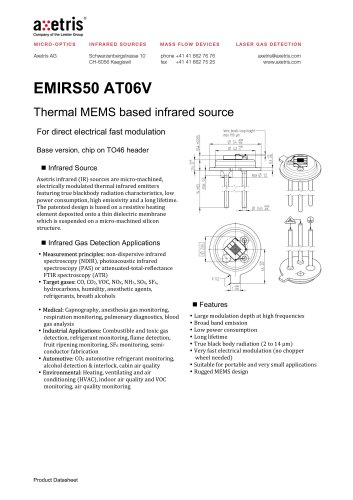

EMIRS50 AT06V

8 Pages

-

EMIRS50 AT06V BR25M

8 Pages

-

EMIRS50 AT06V BC150

8 Pages

-

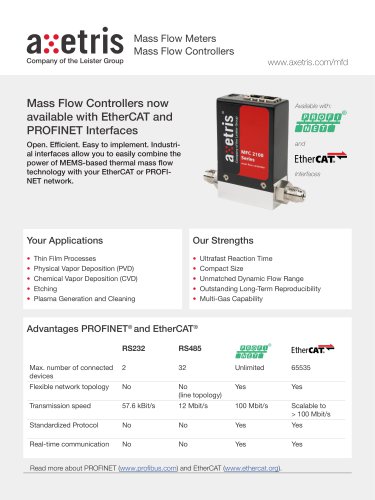

MFD BaseFlo Line

2 Pages

-

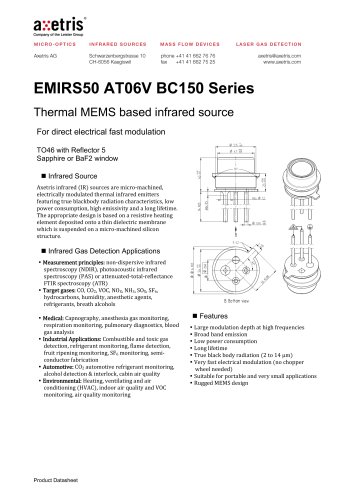

EMIRS50 AT06V BC150 Series

8 Pages

-

Inductively Coupled Plasma

2 Pages

-

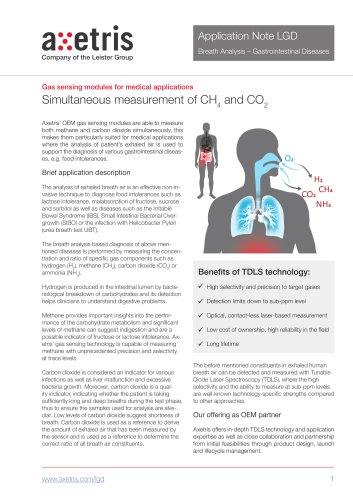

Gas Chromatography

2 Pages

-

MFM / MFC RS-232

24 Pages

-

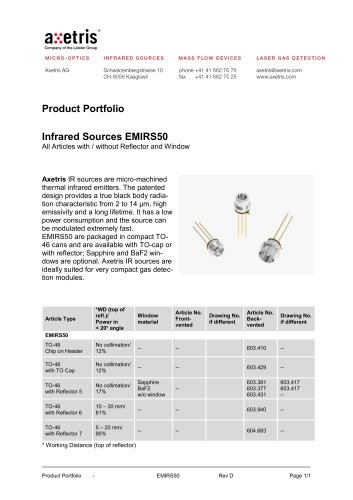

Infrared Sources EMIRS50

1 Pages

-

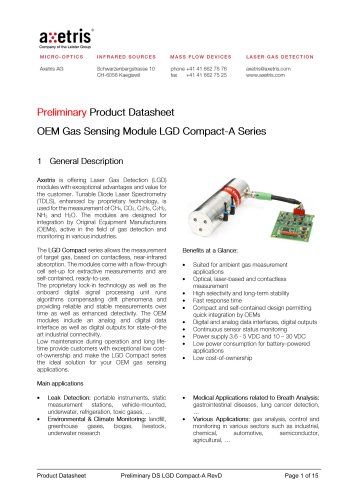

LGDF200 A CH4

8 Pages

-

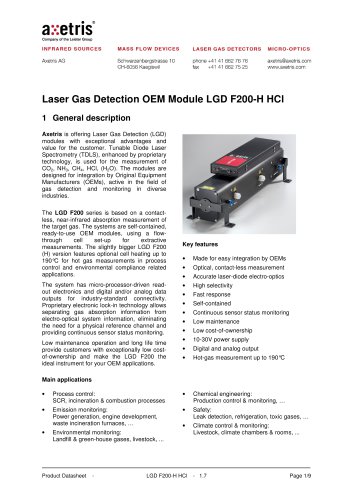

LGDF200 H HCl

9 Pages

-

FL - Infrared Source EMIRS50

2 Pages

-

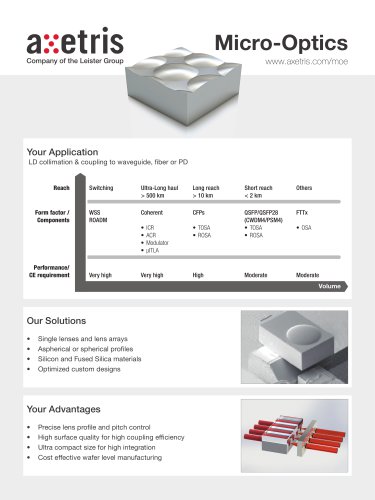

Micro-Optics

2 Pages

-

Infrared Sources EMIRS200

12 Pages

-

DS - LGDF200 H NH3

9 Pages

-

DS- LGDF200 A NH3

8 Pages

-

DS - LGDF200 A CO2

8 Pages

-

FL - Axetris MFD Plus

2 Pages

-

FL - LGD F200P2

2 Pages

-

Reflector

4 Pages

-

MEMS Services

2 Pages