Catalog excerpts

Company of the Leister Group Thin Film Deposition Ultrafast response, flow stability of MFCs deliver key advantages for thin film processes Thin film deposition processes rely on a stable, reproducible and quick gas flow control for sputtering and process gases. The right mass flow product can deliver critical advantages toward achieving high deposition performance. Thin film deposition: Experiencing unprecedented growth Deposition of thin films—coatings from a few nanometers to about 100 micrometers—is a key process step in a number of industries today. Thin film processes such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD) are used in industries ranging from semiconductor fabrication, solar panel production, and the coating of architectural glass. Gas flow control: A key success criterion Gas flow control for sputtering gases (typically Ar), process gases (O2, N2, etc.), as well as for precursors, is absolutely essential in achieving uniform film properties during thin film deposition. Of utmost importance are: • Reproducibility: A highly reproducible gas flow control ensures reproducible thin film properties, thereby minimizing quality and inspection costs • Long-term stability: Long-term stable performance is essential in avoiding deviations in film properties over time. • Quick reaction time: In the coating chamber (usually held at near vacuum conditions), a number of parameters besides gas matrix must be controlled simultaneously and accurately, e.g. temperature and pressure. Since all of these parameters are interdependent, a quick mass flow controller response time lays the foundation for high coating efficiency. • Dynamic range: Gas flow control over a wide flow range (down to a few sccm) is required for various process and precursor gases. Axetris MFC Advantages: S Extremely high repeatability of < 0.15% Of Reading (O.R.) Excellent long-term stability (max. +/- 0.25% F.S. / year) ■/ Quick response time of < 150 ms Excellent dynamic range > 1000:1 provides flexibility in flow range selection with a single device Technology Advantages with the Axetris mass flow technology Axetris mass flow solutions are based on the in-house MEMS chip technology. This combined with smart electronic and software design, delivers key advantages for thin film applications. With Axetris, thin film deposition machine manufacturers have the ideal partner to support throughout the design process.

Open the catalog to page 1

Company of the Leister Group Turndown Ratio High Accuracy Multigas Reaction Time Pressure Coefficient Long-Term Stability Axetris mass flow meters and controllers - Technology advantages for thin film applications Performance benefits at a glance: S Repeatability < 0.15% O.R. > 1000:1 < 0.2% F.S. 0-10% F.S. < 1% F.S. for 10-100% F.S. He, H2, N2, Air, Ar, CO2, O2, etc. < 4 ms (mass flow sensor) < 150 ms (mass flow controller) +/- 0.2% O.R. +/- 0.25% F.S. per/year O.R.: Of Reading; F.S.: Full Scale Mass flow solutions from Axetns are based on the in-house MEMS technology, which delivers key...

Open the catalog to page 2All Axetris AG catalogs and technical brochures

-

Infrared Sources

12 Pages

-

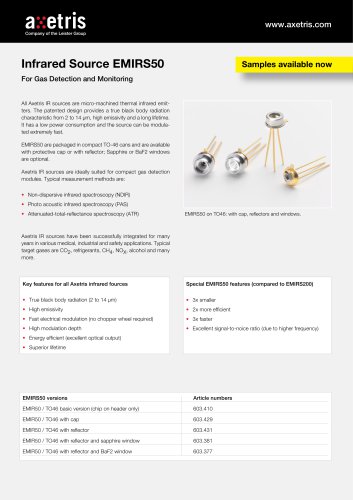

Infrared Sources EMIRS200

1 Pages

-

EMIRS200

2 Pages

-

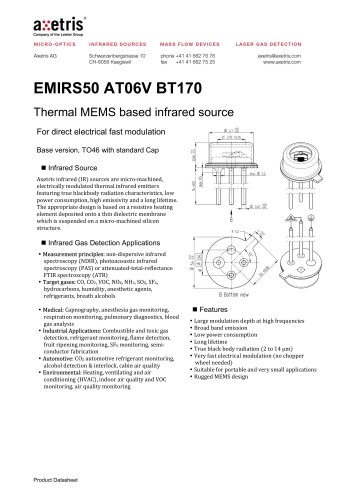

EMIRS50 AT06V BT170

8 Pages

-

EMIRS50 AT06V BR26M

8 Pages

-

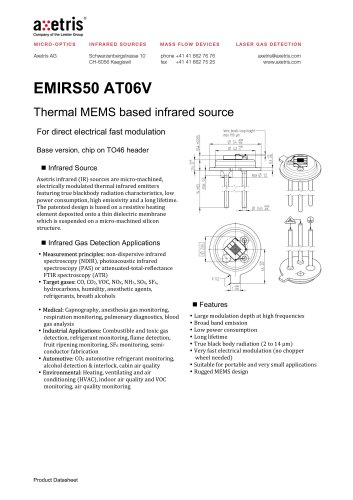

EMIRS50 AT06V

8 Pages

-

EMIRS50 AT06V BR25M

8 Pages

-

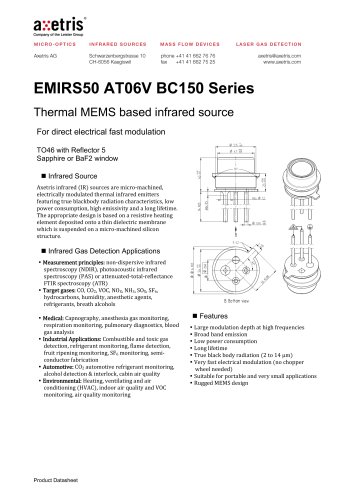

EMIRS50 AT06V BC150

8 Pages

-

MFD BaseFlo Line

2 Pages

-

EMIRS50 AT06V BC150 Series

8 Pages

-

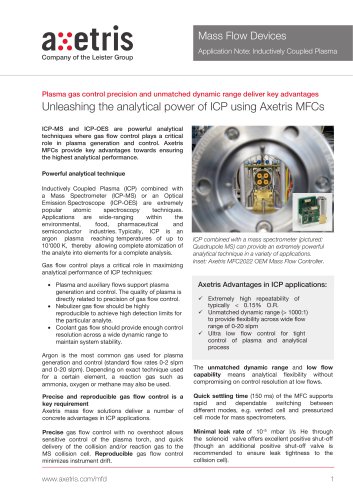

Inductively Coupled Plasma

2 Pages

-

Gas Chromatography

2 Pages

-

MFM / MFC RS-232

24 Pages

-

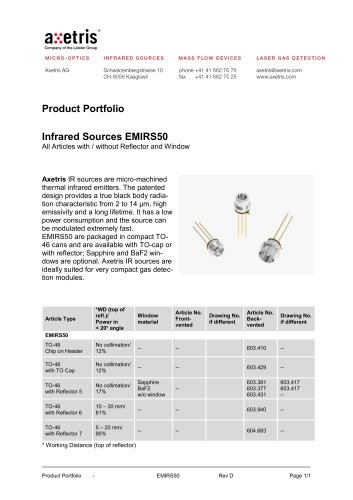

Infrared Sources EMIRS50

1 Pages

-

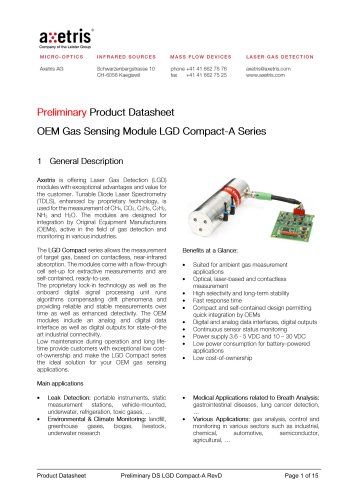

LGDF200 A CH4

8 Pages

-

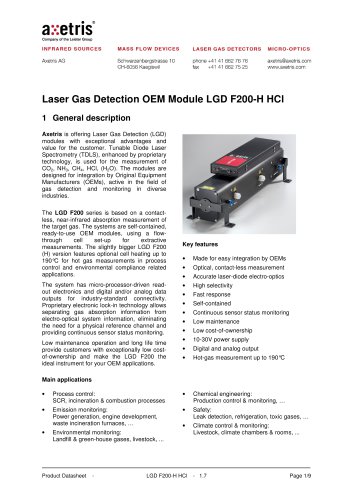

LGDF200 H HCl

9 Pages

-

FL - Infrared Source EMIRS50

2 Pages

-

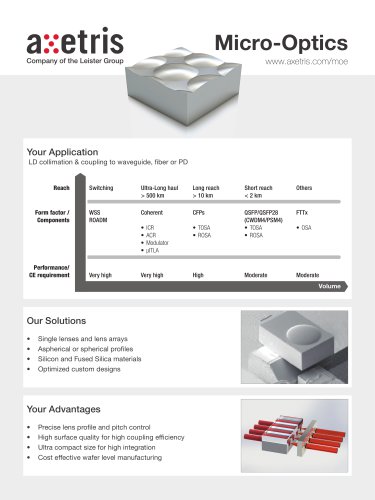

Micro-Optics

2 Pages

-

Infrared Sources EMIRS200

12 Pages

-

DS - LGDF200 H NH3

9 Pages

-

DS- LGDF200 A NH3

8 Pages

-

DS - LGDF200 A CO2

8 Pages

-

FL - Axetris MFD Plus

2 Pages

-

FL - LGD F200P2

2 Pages

-

Reflector

4 Pages

-

MEMS Services

2 Pages