Website:

Avery Dennison Printer Systems Division

Website:

Avery Dennison Printer Systems Division

Group: Avery Dennison

Catalog excerpts

AVERY DENNISON® ADTP2 ECOCUTTM PRINTER SOLUTION INDUSTRY CHALLENGES WITH TODAY’S LABELING SOLUTIONS Manufacturing and distribution centers are challenged with a number of inefficiencies with today’s labeling solutions, such as: producing unnecessary white space on labels to fit a pre-determined standard size, printing millions of blank labels annually, and using label rolls with wasted liner space between each pre-cut label. Now there is a better way. THE AVERY DENNISON ADTP2 ECOCUT SOLUTION: ONE PRINTER FOR ALL LABELING NEEDS The EcoCut Solution: - Uses one continuous label roll in combination with an innovative printer cutting mechanism to produce variable length logistics labels, on demand. - Offers flexibility to print in either peel-and-present or in batch mode: - Peel-and-present - the label is face cut and ready for application while the liner is rerolled - Batch mode - multiple label formats and sizes can be printed at once with the liner intact for label application now, or later Standard die-cut label roll - Eliminates waste, resulting in: - Significant Cost Savings - Increased Productivity - Improved Sustainability EcoCut™ continuous roll COST SAVINGS The EcoCut Solution is designed to reduce overall cost of labeling by up to 40%, due to: - The use of exclusive economical material constructions - Up to 50% more labels per roll means significantly less costs for label materials - Reduction of overall consumption (no matrix waste, reduction in wasted white space on labels) Standard die-cut label (with padded white space) EcoCut label (eliminates padded white space) - Fewer SKUs required, results in a reduction in transportation, converting, purchasing, inventory and warehousing costs Enabling Inventory Visibility | Reducing Labor Costs | Increasing Speed

Open the catalog to page 1

INCREASED PRODUCTIVITY The design of the printer can produce a variety of label formats and lengths on demand all in one label roll. This helps increase productivity due to: - Fewer stops for roll changes - Thin liner results in a decrease of waste handling needs INCREASED SUSTAINABILITY The EcoCut Solution is designed to reduce environmental impact by: - Decreasing transport weight - Reducing CO2 emissions - Generating less volume of waste to landfills (due to thinner liner) DIMENSIONS Height: 12.25” (311 mm) Width: 11.0” (279 mm) Depth: 20.5” (521 mm) Weight: 31 lbs. (14.1 kg) Shipping...

Open the catalog to page 2

ADTP2 ECOCUT™ PRINTER SOLUTION SPECIFICATIONS Font Magnification 1x to 7x 4 to 250 pt. for scalable/ TrueType™ fonts ENVIRONMENTAL Operating Temperature 40° - 104° F (4° - 40°C) for Thermal Direct 40° - 95° F (4° - 35°C) for Thermal Transfer Storage Temperature 15° - 120° F (-9° - 49°C) Relative Humidity 5 - 90% Non-condensing Power Source 90-264 VAC with auto select 50/60 Hz Optional 24 VDC regulator Power Consumption 62 Watts printing, 4 Watts (Sleep mode), Certified Energy Star Compliant WARRANTY Printer One (1) year parts and labor. Full written warranty statement available on...

Open the catalog to page 3All Avery Dennison Printer Systems Division catalogs and technical brochures

-

Tabletop Printer 1

2 Pages

-

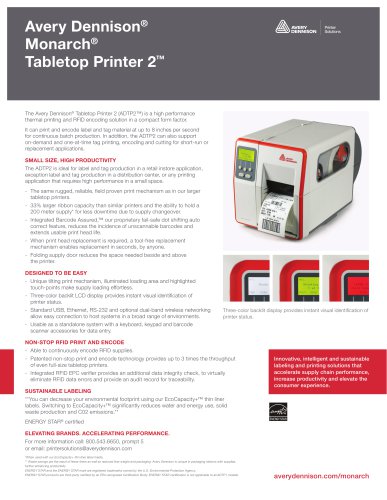

Tabletop Printer 2™

2 Pages

-

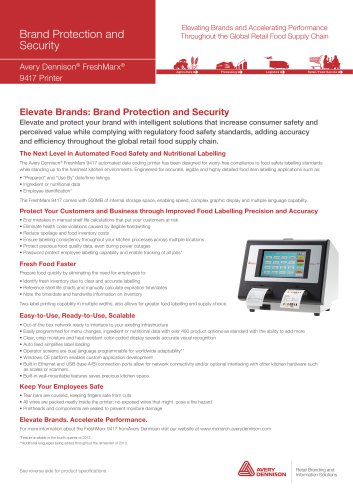

Avery Dennison® Monarch®

2 Pages

-

Fastener Solutions

28 Pages

-

THE RETAILER’S CATALOG SEPT 2016

51 Pages

-

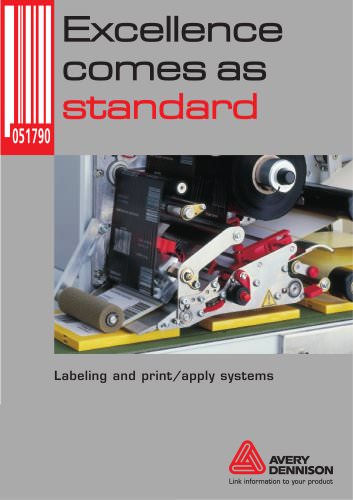

The ALS Generation

6 Pages

-

AP 4.4

2 Pages

-

Thermal Transfer Ribbons

4 Pages

-

RFID label

4 Pages

-

Monarch® 9416® XL® Printer

4 Pages

-

Monarch® 9855? RFID

6 Pages

-

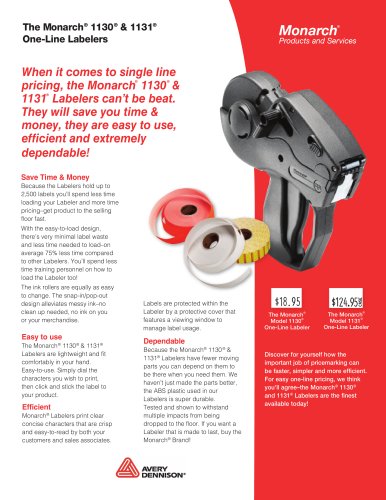

Monarch® Model 1130®

2 Pages

-

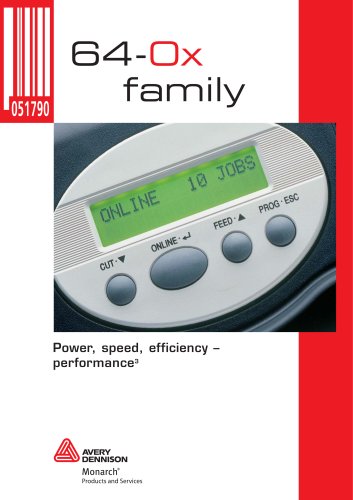

64-0x

4 Pages

-

AP 5.4

6 Pages

-

Monarch® 9825® Printer

6 Pages

-

ALS 380

5 Pages

-

Avery Dennison® 9485

2 Pages

-

ALS 306

6 Pages

-

Monarch® 9906 RFID

2 Pages

-

FreshMarx® M9415? AutoMarx

2 Pages