Catalog excerpts

RUTOTRONIK Fertigungssysteme fur die Elektronikindustrie AUTOTRONIK-SMT GmbH Sulzbacher Str. 111, 92224 Amberg, Germany tel +49 (0) 9621-600 691 fax +49 (0) 9621-600 692 mail office@autotronik-smt.com www.autotronik.de BORISON AUTOMATION CO.,LTD. RUTOTRONIK Fertigungssysteme fur die Elektronikindustrie

Open the catalog to page 1

flUTOTRONIK Fertigungssysteme fur die ELektronikindustrie The latest IGBT Power Diebonder of AUTOTRONIK is introduced below. Its advantages are these multiple types and specifications of materials are compatible with one high-precision mounting equipment at the same time.

Open the catalog to page 2

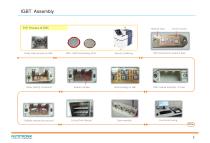

IGBT Assembly Solder Paste printed on DBC Epoxy potting compound Bubbles remove (by vacuum) Heatsink base Busbar installed Curing Oven (Epoxy) Ceramic board Vacuum Soldering DBC laminated to heatsink base DBC module assembly to Case Case assembly Functional testing Done

Open the catalog to page 3

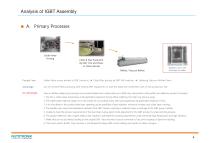

Analysis of IGBT Assembly A. Primary Processes Solder Paste Printing Chips & Dies Placement (by SMT Pick and Placer or others device) Reflow / Vacuum Reflow Bubbles a lot in the interlayer of solder Process Flow : Solder Paste screen printed to DBC (ceramic) → Chips/Dies placing by SMT PnP machine → Soldering (Vacuum Reflow Oven) Use of normal PCBA processing with existing SMT equipment, to save the expensive investment cost of new production line. Vacuum Reflow soldering processing has removed bubbles from solder paste up to 90% only, reduced the cooling effect and defective products...

Open the catalog to page 4

Analysis of IGBT Assembly B. Advanced Processes SV350L Power Die Bonder Tape Feeder of Solder-Plate Multi-platform of Dies Feeding Formic Acid Vacuum Reflow No Bubbles in the interlayer of solder Process Flow : DBC boards carrier loading to SV350L → Solder-plate placing → Chips/Dies placing (Tape/ Wafer/ Tray feeder) → Soldering (Formic Acid Vacuum Reflow) Use the SV350L equipment specially designed for IGBT power module chips mounting, to complete the entire the chips assembly of DBC module : 1. SV350L is compatible with SMT tape feeder, Tray feeder, and Wafer flange feeder to loading and...

Open the catalog to page 5

SV350L Power Die Bonder (Top View) Heads Placement Accuracy Capacity of Placement Size Capacity of Carrier Weight Capacity Feeding System IGBT (DBC) Module Carrier Wafer Flange Transfer-Arm Auto-Wafer System - ± 20um max. 1 600uph / max.2200uph (Solder-Plate + Chips Placement) max. 420x350x20mm max. 8kg (each carrier) Tape feeder (max. 3 sets of Solder-Plate feeder on Platform) Tray feeder (max. 8 Tray carriers @ Tray Cassette) Wafer feeder (max. 25 Wafer Flange @ Wafer Cassette) 6”/ 8”/ 12” Wafer Cassette is selectable Heads ( 4 / 6 ) X-axis Y-axis (Twin Y-axis) Bottom Camera Auto-Tray...

Open the catalog to page 6

Tape Feeder Platform Feeder Platform has 8 slots for 8mm Std. SMT Tape Feeder, or up to 3 Solder-plate Tape Feeder can be installed. Available the types of Solder-plate Tape Feeder (option) as HT2-14 / HT12-16 / HT22-36 and the corresponding solder-plate feeding size is 2*2~14*14mm / 12*12~26*26mm / 22*22~36*36mm Solder-plate is auto-cut on the feeder and length adjustable in range of feeder specification Discharge Port Auto-cutter Keypad + LED screen Feeder Handle Tape reel form Solder-plate (Tape reel form of Solder-Plate)

Open the catalog to page 7

■ Auto-Tray System The Auto-Tray System is a standard feature 8 Tray Carriers can be stored in the Tray Cassette (included) Tray Cassette size: 264*146*H180 mm Storage levels: Capacity of Carrier: max. 245*120*10mm (Thickness of component + tray) max. 25 types of Tray Component for a bonding program (only one material type can be set for each tray carrier) Component Tray Tray Carrier Holder Truck Rail Tray Cassette max. 8 Tray Carrier stored flUTOTRONIK Fertigungssysteme fur die Elektronikindustrie

Open the catalog to page 8

■ Auto-Wafer System Std. with 6”/8” wafer platform ( 8”/12” wafer platform is option) Std. with one wafer cassette (choose one within 6”/ 8” /12” wafer cassette) Wafer Cassette Storage: Flange Diam.: Compatibility : max. 25 types of Wafer Die for a bonding program Truck Rail Wafer Cassette Wafer Flange Holder (Loading Zone) (switchable two sets of diaphragm ring and tracks) max.25 /13 wafer flange in a cassette Large platform for 8"/ 12" wafer Cassette Small platform for 6"/ 8" wafer Cassette

Open the catalog to page 9

Features■ Automation SystemEject-Pin Auto Changer (AEC-3) Auto Nozzle Changer (ANC-16) Fit for various spec. of Wafer Dies placement, 3 Eject-Pin auto exchanging programmable, fastest exchange just 4 sec only Up to 16 Nozzles can be stored for exchange, for wider application of different materials spec., and auto-changing by system programmable Optional Dispensing System for SV-series, it can provide the One-Shop solution of Gel or Solder dispensing requirement

Open the catalog to page 10

SV350L ■ Operation System Autotronik Interactive software built on the Win 10 OS system platform, English / Chinese online switchable and other language selectable (option). The real-time production situation has show on the Intuitive Screen. ±20um placement accuracy was improved by precise positioning system. Feeding platforms editing menu is Simple and Clearly, supported max. 25 component types of each feeding platform of Tray and Wafer. Online software upgrade and remote technical guidance. flUTOTRONIK Fertigungssysteme fur die Elektronikindustrie

Open the catalog to page 11

■ Parameter Table SV350L-4P SV350L-6P Specification Movement Feeding (3 types) XY Placement Accuracy XY Resolution Capacity of Placement Bond Head Bond Head Pitch Size of Component (Die) XY Transmission control Carrier Size Conveyor Height Conveyor System Conveyor Through (1) Auto-Wafer System (3) Tape Feeder Platform Optional Camera Software Physical Nozzle Changing Method Eject-Pin set Changing Method Eject-Pin set type Dispensing System Qty of Camera FOV of bottom camera FOV of Fid-CAM Camera moving at Z-axis Camera Calibration Fiducial Recognitions OS system Control System PCB Layout...

Open the catalog to page 12

Optional Parts Wafer Cassette Ejection Pin Set EP-80 ,pitch = 2.0mm ,net = 13*13mm EP-83S ,pitch = 2.0mm ,net = 13*13mm EP-72 ,pitch = 2.2mm ,net = 14.2*12mm

Open the catalog to page 13All AUTOTRONIK-SMT GmbH catalogs and technical brochures

-

MAS 339 Pro

4 Pages

-

AT530

1 Pages

-

MODEL: BA889CY-E6-V

2 Pages

-

MODEL: AP435

2 Pages