Website:

AUTEFA SOLUTIONS

Website:

AUTEFA SOLUTIONS

Group: China Hi Tech Group Cooperation

Catalog excerpts

AUTEFA Solutions leads the way

Open the catalog to page 1

AUTEFA SOLUTIONS – Experience, Know-How and Competence in Nonwoven Technology AUTEFA Solutions leads the way AUTEFA Solutions represents companies with a long tradition and a history of years of successful participation in the market. Combining the experience of the companies AUTEFA, Fehrer, FOR and Strahm the company stands for high quality, durability and performance made in Europe. AUTEFA Solutions creates innovative technological concepts for nonwoven products by utilizing the skills and practical experience of its employees. The customers benefit from the dynamic flexibility and...

Open the catalog to page 2

AUTEFA Solutions leads the way in carding technology The combination of flexibility, high line speed and process efficiency is mandatory for state-of-the-art carding technology. AUTEFA Solutions offers fully integrated turnkey lines including all components from fiber opening to web drafting. All process steps and corresponding machines are fully integrated into the AUTEFA Solutions control system. All cards are equipped with a controlled air flow using a vacuum system in order to minimise the flow of fibers. Easy access to all components of the card is provided by the “Monoblock” design of...

Open the catalog to page 3

Injection Card The traditional mechanical carding principle using workers and strippers has been replaced by an aerodynamic principle in the Injection Card. The fibers are taken off the worker rollers by an aerodynamic effect generated by specifically shaped devices. This avoids considerable mechanical stress on the fibers which usually applies to traditional carding systems with stripper rollers. THIS PATENTED CARDING PRINCIPLE OF THE INJECTION CARD PROVIDES SOME VERY IMPORTANT BENEFITS: The carding action takes place at the tangent point of two convex surfaces and is very smooth. The...

Open the catalog to page 4

INJECTION CARD WITH TWO DOFFERS INJECTION CARD WITH THREE DOFFERS INJECTION CARD WITH THREE DOFFERS, IN LINE

Open the catalog to page 5

WM 2+2 CARD The Webmaster WM 2+2 Card is designed for high productivity and top quality nonwoven materials. A patented system of two doffers between the two main cylinders of the WM 2+2 Card provides an optimal strip-off at the first cylinder and allows the division of the fiber flow in the intermediate area providing improved blending and fiber distribution on the second cylinder. In addition, the use of two doffers in the intermediate section increases the carding power of the machine with the effect of about two additional worker rollers compared to a traditional card. The standard...

Open the catalog to page 6

CARD WM 2+2 WITH VOLUMETRIC CONTROL CHUTE FEED TYPE CF-S AND SERVOLAP CARD WM 2+2 WITH VOLUMETRIC CONTROL CHUTE FEED TYPE CF-L AND WEIGH BRIDGE DOUBLE DOFFER CARD WITH FANCY ROLL CARD WITH RANDOM ROLLS

Open the catalog to page 7

Fiber Orientation AUTEFA Solutions offers a wide variety of different delivery sections according to the requirements of the web and fibers to be used. The patented EVO-2 and EVO-3 condensing system using a web control roller, enables the achievement of high line speeds without the need of a suction system under the belts. A) Quick change system for parallel or condensed web B) Condensing system for long fibers C) Condensing system D) Condensing system EVO-2 E) Randomising and condensing system F) Randomising system Card Feeding For optimal opening of the fibers, AUTEFA Solutions offers the...

Open the catalog to page 8

Card Regulation Feeding systems of the card can be combined with an inline control of the weight of the fiber matt or alternatively by controlling the fiber density with the “Servolap” system (x-ray). The settings of the feeding system are automatically optimised based on the information provided by the inline control system.

Open the catalog to page 10

Carding Competence Center The AUTEFA Solutions Carding Competence Center (CCC) possesses an industrial scale carding line for the production of needle punched nonwovens with a working width of 3.5 m, combining F.O.R. (carding), Autefa (crosslapping) and Fehrer (needle punching) technology. All process steps are fully integrated, in order to obtain top quality and maximum efficiency from bale opening to winding. Each unit, together with its relevant operating data, is displayed in a process control system for central operational und process control. A further 2.4 m width production line is...

Open the catalog to page 11

AUTEFA SOLUTIONS ITALY S.P.A. Str. Campagnè, 16 · 13900 Biella · Italy T: +39 015 8484 111 · F: +39 015 8491 880 www.autefa.com · italy@autefa.c

Open the catalog to page 12All AUTEFA SOLUTIONS catalogs and technical brochures

-

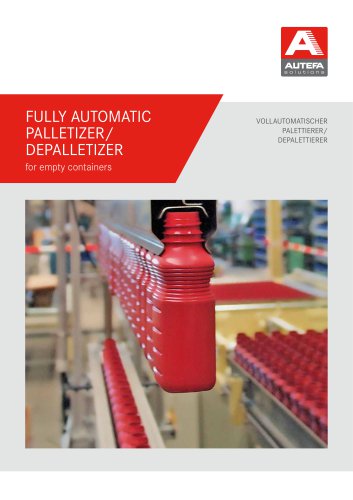

INTRA-WRAP

2 Pages

-

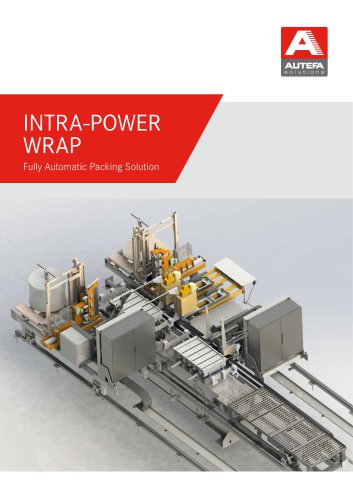

INTRA-POWER WRAP

2 Pages

-

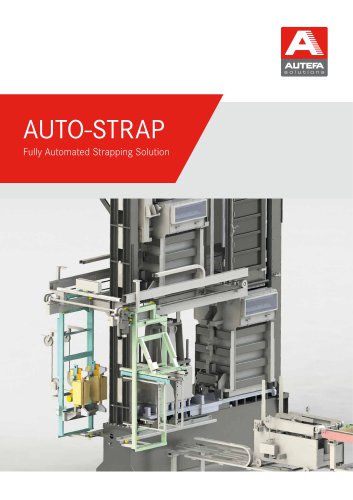

AUTO-STRAP

2 Pages

-

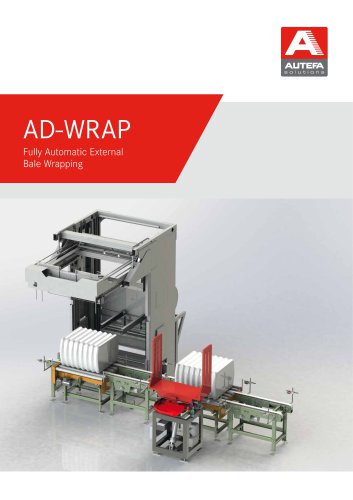

AD-WRAP

2 Pages

-

BSS

2 Pages

-

BALING TECHNOLOGY

24 Pages

-

NONWOVENS LINES

28 Pages

-

UNI-FORK

2 Pages

-

NONSTOPULTRA

2 Pages

-

LIFT BOX COMPACT / LBC

2 Pages

-

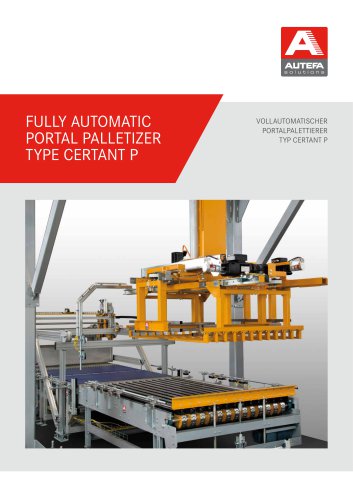

Autefa Solutions Automation

16 Pages

-

NEEDLELOOM Fehrer STYLUSONE

8 Pages

-

NEEDLEPUNCHING

12 Pages

-

i-POINT

2 Pages

-

CROSSLAPPER UnilinerONE

8 Pages

-

CROSSLAPPING

8 Pages

-

AERODYNAMIC WEBFORMING

8 Pages

-

Web Master FUTURA

2 Pages

-

CARDING LINES

20 Pages

-

FIBER OPENING AND BLENDING

12 Pages