Catalog excerpts

BALING TECHNOLOGY AUTEFA Solutions leads the way

Open the catalog to page 1

AUTEFA Solutions leads the way AUTEFA Solutions is the global market leader in the field of fully automatic bale packing systems for staple fiber and tow. AUTEFA Solutions offers the entire range from fiber transport to the baler, as well as bale transport and storage of the finally pressed, wrapped and strapped bales in bale warehouses. Today, a fully automated baling process with bale transport directly to the warehouse has become utmost essential, as due to the growing capacities of fiber lines, manual packing of bales would be impossible without massive use of labor and space. Highest...

Open the catalog to page 3

LIFT BOX COMPACT/ LBC Double Lift Box Baler The Lift-Box-Compact baler is the most successful baler in the world market during the last 20 years. More than 3000 balers of the AUTEFA Solutions double box system have been sold worldwide. Two boxes, one at the pre-press and the other one at the main-press guarantee a perfect bale shape for difficult fiber properties, e.g. siliconized fibers, short cut fibers, low melt fibers, mineral fibers. These fibers need a box at the main-press to guide the fibers in the right position during pressing and bale forming. The baler is available as full...

Open the catalog to page 4

NONSTOP-ULTRA Single Box Baler The economic Nonstop Ultra baler has a main-press pressing capacity of 150-400 t. The baler distinguishes itself with fast speed and less space requirement. During the packing process the fibers will be protected. High security standards and easy operation are additional advantages. In a pre-press the fibers will be compacted to a pre-press bale which will be transferred to the main- press without a press box. Due to the fact that the fiber transfer is done without friction to the fiber and the already prepared packing material at the pre-press ram, there will...

Open the catalog to page 6

Automatic Packing Solutions • INTRA-WRAP / IW Fully Automated Packing Solution • INTRA-POWER WRAP / IPW Fully Automated Packing Solution • AD-WRAP Fully Automatic External Bale Wrapping THREE SOLUTIONS FOR DIFFERENT TARGETS AND CUSTOMER NEEDS IN COMBINATION WITH: • NONSTOP-ULTRA Single Box Baler • LIFT BOX COMPACT / LBC Double Lift Box Baler • UNI-FORK Transfer Fork

Open the catalog to page 8

INTRA-WRAP / IW Fully Automated Packing Solution More than 120 staple fiber lines have been automated with the Intra-Wrap packing system. There is no other automatic wrapping and strapping system that is used equally often. Capacities of approx. 28 bales/h are achieved with Intra-Wrap and different wrapping materials can be used, e.g. PE-film or PP-woven. Intra-Wrap can be integrated in the Lift-Box-Compact or Nonstop-Ultra balers. SPECIAL FEATURES: SPECIFIC ADVANTAGES: 5 – 28 bales/h Can be integrated in Lift-Box-Compact or Nonstop-Ultra balers as full automatic packing 3 sheet packing...

Open the catalog to page 9

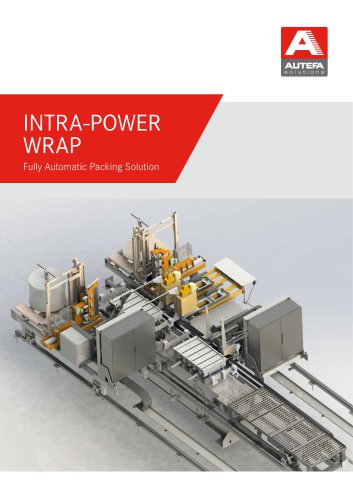

INTRA-POWER WRAP / IPWFully Automated Packing Solution Intra-Power Wrap is a further development of this fully automatic wrapping and strapping system and thus also an answer on the increasing demands regarding baling press technology caused by the new high capacity fiber lines. Intra-Power Wrap can be integrated in Lift-Box-Compact or Nonstop-Ultra balers. SPECIAL FEATURES: • 5 - 62 bales/h • The extreme high capacity can be realised due to a belly wrap process with 2 film coils moving parallel to the bale • Welding of the belly wrap at 2 sides: - With ultra-sonic for PP-woven - With...

Open the catalog to page 10

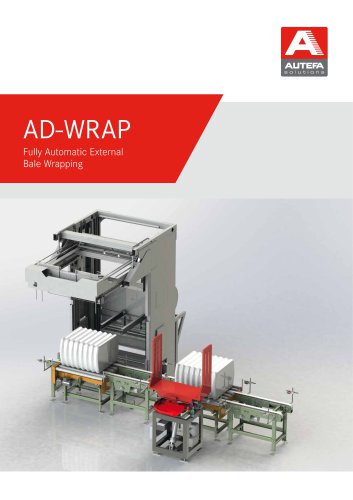

AD-WRAP Fully Automatic External Bale Wrapping The patented bale wrapping machine Ad-Wrap is a high-quality solution for bale wrapping outside of the baler providing plenty concepts of utilization at comparatively low costs. This efficient technology is a perfect upgrade for manual balers and therefore leads to a fully automatic packing process. SPECIAL FEATURES: 5 – 60 bales/h One bale wrapping machine Ad-Wrap can be combined with several main-presses or one single-baler Changing of the packing material without interruption of the baler Can be used for manual installations as an automation...

Open the catalog to page 11

AD-WRAP: Fully Automatic External Bale Wrapping

Open the catalog to page 12

BALES PACKED BY AD-WRAP Fully Automatic External Bale Wrapping Ad-Wrap The wrapping machine Ad-Wrap offers an easy and economical solution to upgrade manual installation to a fully-automatic one. Ad-Wrap increases the production volume for fiber lines. Such a modification does not interfere with existing control systems and can be done with almost every baling press. SPECIFIC ADVANTAGES: The overlapping end elastic film bags guarantee a sealed bale packing No contamination due to insects or water Strapping belts protected by film above Low risk of strapping belt breaking Easy unpacking of...

Open the catalog to page 13

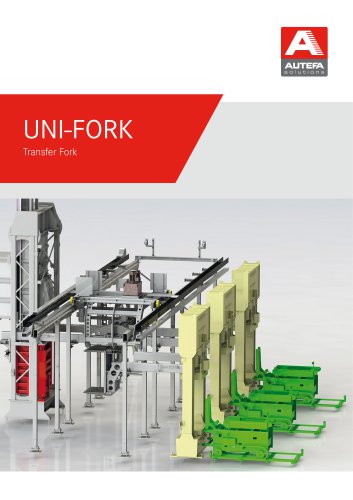

UNI-FORK Transfer Fork The Uni-Fork optimizes the process of bale pressing and increases the efficiency and capacity. The Uni-Fork intelligent concept is a robotic solution which is working together with several fiber presses and combines the operation of several pre- and main-presses. The central idea is a robotic fork, which is acting as a flexible transfer truck for one or more pre-presses and to operate one or more main-presses. The cut staple fibers of several independent working fiber lines are fed to different pre-presses. These fibers will be pre-compacted and prepared in a press...

Open the catalog to page 14

UNI-FORK with 3 pre-presses and 6 main-presses

Open the catalog to page 15

UNI-FORK Transfer Fork The UNI-FORK intelligent concept saves costs with a very small investment for a fully automatic process while improving quality. One AUTEFA Solutions UNI-FORK operates one or more pre-presses and one or more main-presses. The system leads to a strong reduction of personnel costs, high availability of the machine and a short amortization period. Transfer Fork UNI-FORK

Open the catalog to page 16

UNI-FORK with 1 pre-press and 2 main-presses

Open the catalog to page 17

AUTOMATION OF TOW INSTALLATIONSTow Plaiters & Balers Various technological requirements render the automation of tow installations a very demanding task. According to the specific requirements AUTEFA Solutions provides specialized equipment for: • Converter-Tow • Compact-Tow • Acetat-Tow (cigarette tow) An automation of the entire process from the tow plaiter to the bale transport is possible due to the modular design. SPECIAL FEATURES: • Tow plaiter The tow is plaited in moveable containers. The plaiting procedure can be controlled on all three axes individually. Additionally the tow...

Open the catalog to page 18All AUTEFA SOLUTIONS catalogs and technical brochures

-

INTRA-WRAP

2 Pages

-

INTRA-POWER WRAP

2 Pages

-

AUTO-STRAP

2 Pages

-

AD-WRAP

2 Pages

-

BSS

2 Pages

-

NONWOVENS LINES

28 Pages

-

UNI-FORK

2 Pages

-

NONSTOPULTRA

2 Pages

-

LIFT BOX COMPACT / LBC

2 Pages

-

Autefa Solutions Automation

16 Pages

-

NEEDLELOOM Fehrer STYLUSONE

8 Pages

-

NEEDLEPUNCHING

12 Pages

-

i-POINT

2 Pages

-

CROSSLAPPER UnilinerONE

8 Pages

-

CROSSLAPPING

8 Pages

-

AERODYNAMIC WEBFORMING

8 Pages

-

CARDING TECHNOLOGY

12 Pages

-

Web Master FUTURA

2 Pages

-

CARDING LINES

20 Pages

-

FIBER OPENING AND BLENDING

12 Pages