Website:

AUMA

Website:

AUMA

Group: AUMA

Catalog excerpts

Test bench PV 1405 for testing and setting electric actuators Product description

Open the catalog to page 1

Applications Wherever there are pipelines and valves to be automated, you can find electric actuators. In large-scale plants such as power plants or refineries, several hundreds of these devices are used. The PV 1405 test bench allows quick and efficient performance of the specified regular revision work on the actuators. Water sector : Conventional power plants (coal, gas, oil) : Hydroelectric power plants : Geothermal power plants : Solar thermal power plants Sewage treatment plants Water treatment plants Drinking water distribution Seawater desalination Steel construction for water...

Open the catalog to page 2

Summary - Functions, equipment 7 Data input and recording 8 Calibrating the test bench 16 Quality is not just a matter of trust 19 Solutions for a world in motion This brochure will provide you with an overview of the functions and applications of the AUMA PV 1405 test bench. It can be used as the basis to determine whether a device is suitable for the chosen application. The test benches are tailor-made for your requirements. Via the field service you can contact the AUMA engineers. With your input, we can determine the ideal device con- figuration. On this basis, you will receive an...

Open the catalog to page 3

Actuators for testing When will a test be performed and which functions are tested? AUMA actuators are designed to perform their duty over a number of years without any maintenance. When will a test be performed? In large-scale plants such as power plants or oil refineries, regular, often annual inspections of all components are stipulated. Several hundred electric actuators are sometimes used in plants like these. Which functions are tested? Revisions in nuclear power plants require detailed inspections. For electric actuators this includes, for example, ■ testing the electrical contacts...

Open the catalog to page 4

[1] Multi-turn actuators SA 07.1 – SA 16.1/SAR 07.1 – SAR 16.1 SAN 07.1 – SAN 16.1/ SARN 07.1 – SARN 16.1 ■ Torques from 10 to 1,000 Nm The SAN and SARN versions are approved for use in nuclear power plants (outside containment). [2] Explosion-proof multi-turn actuators SAExC 07.1 – SAExC 16.1/ SARExC 07.1 – SARExC 16.1 ■ Torques from 10 to 1,000 Nm For the PV 1405 test bench, the difference between the explosion-proof actuators and the non explosion-proof actuators is the electrical plug/socket connector. For explosion-proof actuators a special adapter is required. [3] Multi-turn actuators...

Open the catalog to page 5

[1] Control cabinet The control cabinet contains the complete power electronics to control the actuator motors. As standard, actuators with 3-phase AC and 1-phase AC motors up to a supply voltage of 700 V can be tested. To control DC motors, a second control cabinet with the required electronics can be connected to the control cabinet. The test and setting software runs on an industrial computer with computer connection module. In addition, the control cabinet contains ■ a 3-phase power measurement module, ■ a 3-phase current measurement module with two current measuring ranges ■ a...

Open the catalog to page 6

Summary – Functions, equipment Standard Option Actuators for testing SA 07.1 – SA 16.1 multi-turn actuators Explosion-proof actuators Actuators with integral controls Actuators with 3-phase AC motor Actuators with 1-phase AC motor Actuators with DC motor Data input/recording Multilingual software Manual input Actuator database in the factory Entry of customer-specific device data Recording of test results Characteristic curve presentation Automatic test sequence Wiring check Motor tests Setting the torque switching Checking the manual change-over mechanism Valve dependent settings...

Open the catalog to page 7

Data input and recording Data input is necessary prior to testing. The required voltage is provided on the basis of this information. The data is also required as a reference for the test and setting procedures. Basically, the following data is required: ■ Actuator type Output speed/operating time Wiring diagram number Stroke/swing angle Type of position feedback signal Motor type Voltage supply/frequency The test software supports several languages. The language can be set independently of the language of the operating system. The translations of the field names are stored in a database...

Open the catalog to page 8

Data input The actuator data can be manually transferred from the name plate of the device or the actuator datasheet to the test bench software. The test bench contains a database where the data records can be stored. A search function enables you to quickly find and select actuators, even if the number of data records is large. Input mask for the actuator data Actuator database programmed in the factory The data of all delivered actuators is stored at AUMA. The actuator data can be found under the order number (com- mission number) of the device. If you send a list containing the order...

Open the catalog to page 9

Data input and recording Recording of the test results/inspection records The result of each test performed is automatically trans- ferred to a log and saved with the date and time. In addition, the name of the person performing the test is stored. The person performing the test is identified via the user name when logging on to the program. The test results can be printed in a standardised inspection record. ipilltfpT rflHI A printable inspection record can be created using a report generator by entering selected data from the log into Inspection record from an AUMA test bench. The form...

Open the catalog to page 10

Characteristic curve presentation The determination of measured values is one thing, the evaluation of the data is another. If the measured values are outside of the given limits, the causes have to be determined. The test bench software supports the analysis by providing the option to present the measured results as a curve. This is valid for all data records stored in the log. So-called multiplots can be used to compare the results of several mea- surements. The evolution of a measured value can therefore be compared over longer periods of time. Torque curves of an actuator which were...

Open the catalog to page 11All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

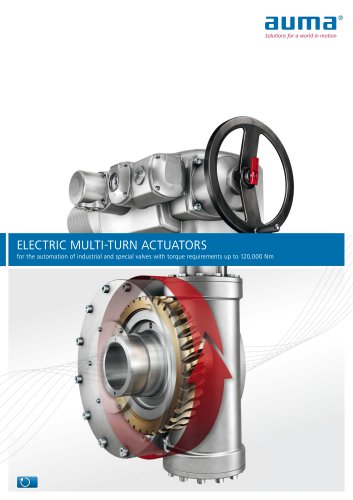

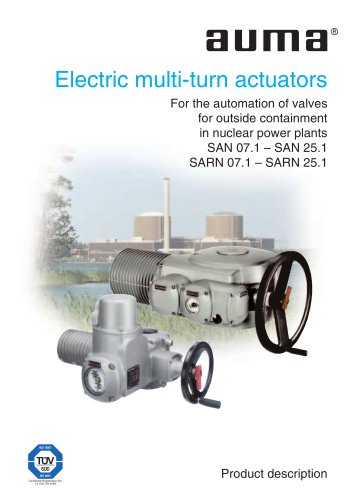

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Service device PV 788 B

4 Pages

-

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages