Catalog excerpts

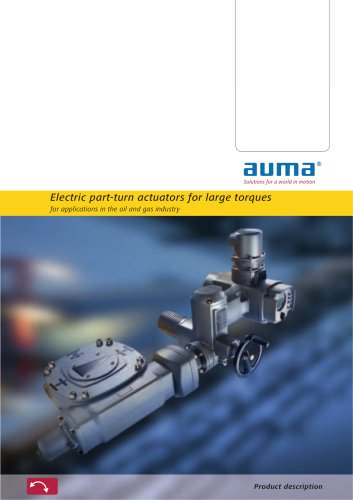

Electric part-turn actuators with integral controls for applications in the oil and gas industry Product description

Open the catalog to page 1

The actuator specialist AUMA are one of the leading manufacturers of electric actuators, actuator controls and valve gearboxes for the automation of industrial valves in the oil and gas industry. AUMA have more than 45 years of experience in research & development and manufacture of electric multi-turn and part-turn actuators. AUMA manufacture their products in the two German plants, Muellheim and Ostfildern. Three service centers, respectively in Cologne, Magdeburg and Munich, have been set up to offer service support. 2,200 employees belong to the AUMA group worldwide. AUMA automate...

Open the catalog to page 2

AUMA actuators for the oil and gas industry 5 Basics - Main functions of actuators 8 Basics - Controls concepts 10 AMExC and ACExC actuator controls 12 Operation and clarity - ACExC local controls 14 Communication - Tailor-made interfaces 18 Communication and device integration - SIMA Master Station 22 Electrical and valve connection 31 Particular conditions - Local adaptations possible! 32 Safe and reliable - in any circumstance 33 Prevention, service life, maintenance - ACExC as test engineer 34 Quality is not just a matter of trust 48 Solutions for a world in motion This brochure will...

Open the catalog to page 3

Applications Tank farms Loading jetty Storage Distribution Manifold Metering Separators Cracker & coker Refining & treatment Fire fighting Isolation ESD applications Wellhead control Drilling & exploitation Transmission Separators Gas lift Manifold Terminals Pipelines Pumping stations Booster Pressure reduction Fuelling

Open the catalog to page 4

SGExC part-turn actuator with ACExC controls GS part-turn gearbox with SAEx .2 multi-turn actuator AUMA actuators for the oil and gas industry AUMA part-turn actuators are used wherever the automation of a valve requires a part-turn movement, e.g. when using butterfly valves or ball valves. For a part-turn movement, less than one rotation at valve input is required for a complete travel. A typical requirement is a swing angle of 90°. AUMA SGExC part-turn actuators AUMA SGExC part-turn actuators are designed to meet the special requirements in the oil and gas sector. They are approved...

Open the catalog to page 5

The environmental conditions in the oil and gas industry are mostly extreme. Salt-laden air in offshore applications, aggressive atmospheres in refineries or rough operation - AUMA devices must operate reliably over many years without major maintenance requirements under all conditions. For this reason, AUMA have focussed on making their devices resistant to the most unfavourable conditions and have adapted protective measures to the state-of-the-art technology. Ambient temperatures AUMA actuators are used in both hot and cold environments. Adapted versions with large temperature ranges are...

Open the catalog to page 6

Corrosion protection AUMA corrosion protection is one of a kind in the world of actuators. Based on chemical preliminary wet treatment with subsequent double powder coating of individual parts, the standard corrosion protection already efficiently protects against corrosion even under the most unfavourable conditions while providing high mechanical resistance. In compliance with the corrosivity categories according to EN ISO 12944-2, various AUMA corrosion protection levels are provided to suit the different applications. Colour The standard colour is silver-grey (similar to RAL 7037)....

Open the catalog to page 7

OPEN-CLOSE duty and positioning duty AUMA SGExC actuators are suitable for open-close duty and positioning mode. Positioning duty Actuators for open - close duty are appropriate for automating shut-off valves. They are rarely operated; when operated, they cover the complete swing angle. The time difference between two travels can amount to minutes or even to months. One or several predefined intermediate positions are used to set the required flow rate through a pipeline for example. For this type of application, the intervals between two operations are generally considerably shorter than...

Open the catalog to page 8

Switching off in the end positions One of the key actuator functions is the automatic cut-off once an end position is reached. Two different mechanisms are available for SGExC part-turn actuators and are applied depending on the type of valve. Limit seating Switching points for end positions are set in the actuator. As soon as the set switching point is reached, controls automatically switch off the actuator. Torque seating This type of seating is used if the valve has to be moved to end position CLOSED at a defined torque to ensure correct seating. As soon as the preset torque is applied...

Open the catalog to page 9

Power supply, e.g. 400 V 3-ph AC current AUMA NORM With AMExC integral controls With ACExC integral controls TSC TSO Basics - Controls concepts In principle, AUMA actuators may be integrated within any automation system. The state-of-the-art solution is to equip the actuator with integral controls to eliminate the time-consuming and costly engineering, installation and documentation for external controls. A further benefit in favour of integral controls is the easy commissioning. External controls For this controls concept, actuators contain no or only few electronic components. All...

Open the catalog to page 10

Integral controls Actuators with integral controls are immediately ready for use. The controls are perfectly adapted to the actuator. As soon as the power supply has been established, the actuator can be operated via the operation elements on the local controls. The actuator can be completely set on site, without requiring direct connection to the DCS. Only operation commands and feedback signals are still exchanged between the control system and the actuator. Motor switching is performed within the device and without delay. The actuators can be equipped with AMExC or ACExC integral...

Open the catalog to page 11

reii'PrMi fc*olDr»rtTuli rKatllnlir AmloMginr |J CHI'HIUI mnlDi piiilFi linn i1»v-tF iPTn-TTfrr-^lgri t*ir HuEbi praltcliQn irtKlirKhtrtunl Infirm nn.ni •_DCII zor\\nA Integration within the DCS - AMExC and ACExC actuator controls The integral controls evaluate the actuator signals and operation commands and automatically perform the required switching procedures without delay, using the nstalled switchgear, reversing contactors or thyristors. After analysis, the controls supply the actuator signals as feedback signals to the host level. The integral controls allow for local actuator...

Open the catalog to page 12All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

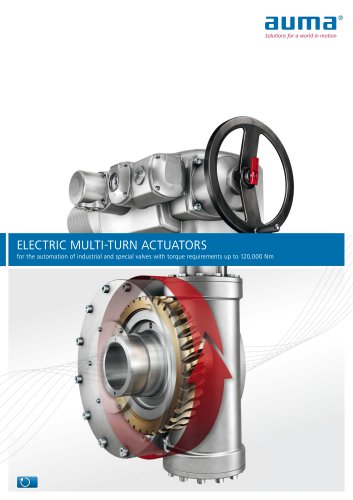

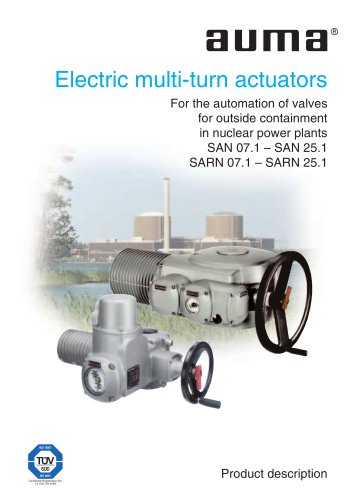

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages