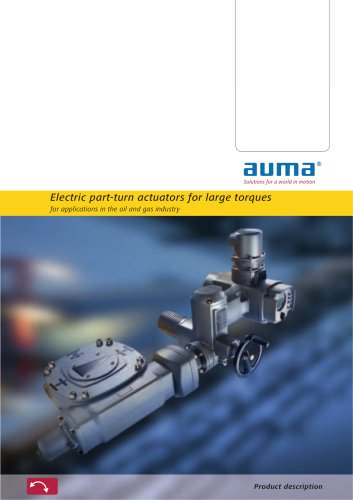

Electric part-turn actuators for large torques Combinations consisting of multi-turn actuators SA and part-turn gearboxes

1 /

20Pages

Catalog excerpts

Solutions for a world in motion Electric part-turn actuators for large torques tions consisting of multi-turn actuators SA and part-turn gearboxes GS Product description

Open the catalog to page 1

The actuator specialist AUMA are one of the leading manufacturers of electric actuators, actuator controls and valve gearboxes for the automation of industrial valves worldwide. AUMA have more than 45 years of experience in research & development and manufacture of electric multi-turn and part-turn actuators. AUMA manufacture their products in the two German plants, Muellheim and Ostfildern. Three service centers, respectively in Cologne, Magdeburg and Munich, have been set up to offer service support. 2,200 employees belong to the AUMA group worldwide. AUMA automate valves AUMA actuators...

Open the catalog to page 2

Contents The actuator specialist 2 Large torque range 5 Service conditions 6 Modular concept 9 Design principle 12 Technical data 14 Certificates 19 Solutions for a world in motion This brochure will provide both the beginner and the expert with an overview of the functions and applications of multi-turn actuator/part-turn gearbox SA/GS e combinations. It can be used as the basis to determine the suitability of a device for the chosen application. 12.06.12 This brochure deals mainly with the device characteristics arising from the combination of both devices. For detailed information on SA...

Open the catalog to page 3

Applications Power Oil & gas : Conventional power plants (coal, gas, oil) : Hydroelectric power plants : Geothermal power plants : Solar thermal power plants : Biogas power plants : : : : : Water sector Industrial and special solutions : : : : : 4 | Sewage treatment plants Water treatment plants Drinking water distribution Seawater desalination Steel construction for water systems Exploration, offshore plants Refineries Distribution Gas tanks Tank farms : Air conditioning : Food industry : Chemical/pharmaceutical industry : Steel mills : Paper industry : Cement industry : Mining

Open the catalog to page 4

AUMA multi-turn actuator/part-turn gearbox combinations cover a large torque range from a few hundred up to 675,000 Nm. This ensures that AUMA products are suitable to automate valves of various sizes and pressure levels within any plant. All actuators are integrated into the DCS using standardised control technology. [1] 1] [1] Multi-turn actuator SA 07.2 with part-turn gearbox GS 50.3 ■ Torques up to 500 Nm [2] Multi-turn actuator SA 35.1 with part-turn gearbox GS 630.3 ■ Torques up to 675,000 Nm [2] Large torque range |5

Open the catalog to page 5

AUMA actuators are used worldwide; in all climatic zones, in industrial plants of all kinds under special local ambient conditions. AUMA devices have to operate reliably and for a long time under any conditions without requiring major maintenance work. For this reason, AUMA have focussed on making AUMA devices resistant to the most unfavourable conditions and have adapted protective measures to the state-of-the-art technology. Enclosure protection Multi-turn actuator with mounted gearbox SA multi-turn actuator and GS worm gearbox combinations are supplied in enclosure protection IP 68-3...

Open the catalog to page 6

Corrosion protection Efficient corrosion protection is a major factor to guarantee a long service life. The AUMA corrosion protection system is based on double-layer coating. In compliance with the corrosivity categories according to EN ISO 12944-2, various AUMA corrosion protection levels are provided to suit the different applications. Colour The standard colour is silver-grey (similar to RAL 7037). Other colours are possible on request. Gearboxes in size 160.3 and larger are equipped with primer coating; factory finish coating is available as an option. AUMA Classification of...

Open the catalog to page 7

Modular concept AUMA's claim is to be able to offer automation solutions to suit any valve. The product range consisting of sophisticated components forms the basis for many combination options due to standard d interfaces. [2] [1] SA .2 multi-turn actuators They play a crucial role within the product range. The speed range comprises 4 – 180 rpm, their torque range covers 10 – 32,000 Nm. [2] Integral controls Actuators with integral controls AM or AC are immediately ready for use. The integral controls contain switchgear units, power supply unit, interface to the D0CS and the ability to...

Open the catalog to page 8

[6] GS part-turn gearbox variants Four variants enhance options for optimum adaptation. This is due to the arrangement between worm shaft and worm wheel and the direction of rotation at output drive, with reference to a clockwise rotating input shaft. ■ LL: Worm shaft left from worm wheel, counterclockwise rotation at output drive (red arrow) ■ LR: Worm shaft left from worm wheel, clockwise rotation at output drive (blue arrow) ■ RL: Worm shaft right from worm wheel, counterclockwise rotation at output drive (red arrow) ■ RR: Worm shaft right from worm wheel, clockwise rotation at output...

Open the catalog to page 9

Design principle [5] Pointer cover The large pointer cover provides information on th l iti ti l follows the valve th l the valve position. It continuously f ll movement and consequently serves the purpose of running indication. In case of high enclosure protection requirements, AUMA recommend replacing the pointer cover by a protection cover [5a]. The protection cover is required for buried service. [6] Coupling The separate coupling enables easier mounting f the b to the l Upon request, th t the of th gearbox t th valve. U coupling is supplied with a suitable hole for the valve shaft. The...

Open the catalog to page 10

[7] Valve mounting flange In compliance with EN ISO 5211. [11] [10] [9] [8] Primary reduction gearing (option) The primary reduction gearings utilise planetary or spur gear stages to reduce the required input torque. [9] Flange for mounting a multi-turn actuator In compliance with EN ISO 5210 or DIN 3210. As an alternative, a handwheel shaft can be fitted to mount a handweel when dealing with a manually operated valve. | 12

Open the catalog to page 11

[1] GS part-turn gearboxes Size GS 200.3 with primary reduction gearing is shown. [2] Gearbox housing The housing is made of cast iron. If extreme loads from outside have to be considered, AUMA recommend using spheroidal cast iron housings. [3] Worm wheel and worm shaft They form the core components of the gearbox. The design allows high reduction within one gear and has an important self-locking effect thus preventing valve position displacement in case external forces act upon the closing element. As standard, the worm wheel is made of spheroidal cast iron. Certain applications require...

Open the catalog to page 12All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

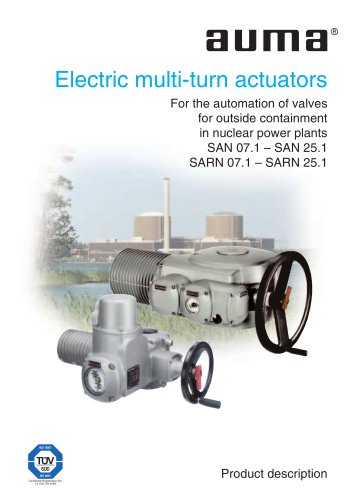

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages