Catalog excerpts

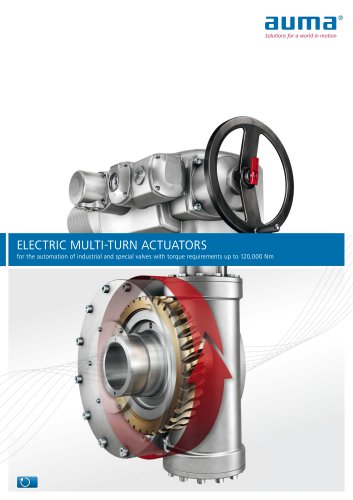

ELECTRIC MULTI-TURN ACTUATORS for the automation of industrial and special valves with torque requirements up to 120,000 Nm

Open the catalog to page 1

Offering the perfect actuator automating any valve – this is the milestone dened by AUMA. The new sizes of the GHT gearbox type range play a key role within AUMA's modular product portfolio. The abbreviation “HT” of the gearbox name GHT stands for “High Torque”. Wide application range SA multi-turn actuators and GHT gearboxes are available for both open-close and modulating duties and are also approved for use in potentially explosive atmospheres. The combinations can thus be used in technical process plants of the most different sectors – from water management and power plant sector right...

Open the catalog to page 2

Explosion protection Both multi-turn actuators and gearboxes were tested and certied in close collaboration with national and international certication bodies. Approvals have been obtained from authorities worldwide, including ATEX (Europe), IEC (international), FM (USA) and ROSTECHNADSOR/EAC (TR-CU) for Russia. Technical data Ambient temperatures > –40 °C to +120 °C > –40 °C to +60 °C for explosion-proof devices SA 35.1 COMBINED WITH GHT 800.3 > Torques up to 80,000 Nm The combinations are also available in reproof version and will remain fully operable for 30 minutes at temperatures up to...

Open the catalog to page 3

SA/GHT combinations can be used for all valves requiring a rotary movement for automation, including gate valves, globe valves or special valves such as double block and bleed valves. No matter whether standard valve design or special valves are involved: there is no standard solution for valve automation. The valve requires the actuator to provide either torque or thrust at de ned running speed via a certain period in compliance with the respective type of duty. On the other hand, the actuator has to be integrated into an existing distributed control system with various functional...

Open the catalog to page 4

AUTOMATION OF COKER VALVES DAMPER AUTOMATION Delayed coking systems transform the residual oil generated when rening crude oil and crack it into gas oil and petroleum coke. The heart of the plant is a coke drum with a height of more than 40 metres where the conversion processes take place at high temperatures. Once the process is nished, both ends of the drum have to be opened to discharge the coke. By using automated special valves, manual opening, which is both dangerous and time-consuming while requiring large numbers of personnel, becomes obsolete. Large dimension dampers in various...

Open the catalog to page 5

DESIGN GHT worm gearboxes The hardened and ground tooth anks of the worm shaft combined with the worm wheel made of bronze ensure low wear and guarantee an exceptionally long lifetime of these gearboxes. The worm shaft with anti-friction bearing ensures high effi ciency and prevents critical warming of the gearboxes for long operating times. Optimised housing design reduces weight and consequently the load to be borne by the valve. Housing parts are made of lamellar graphite cast iron (GJL). On request they are available in spherulitic graphite cast iron (GJS). As an option, the GHT is also...

Open the catalog to page 6

Integral actuator controls (option) Controls, in our example the microprocessor controlled AC, are available with different interfaces to the DCS – either for parallel signal transmission or eldbus communication. Probus DP, Modbus RTU, DeviceNet as well as Foundation Fieldbus are supported. DCS connection using HART or wireless HART is also possible. 2 Advanced diagnostic functions enable preventive maintenance and integration of actuators into asset management systems. The integral local controls allow for local actuator operation. Electric SA multi-turn actuator The torque of the electric...

Open the catalog to page 7

AUMA Riester GmbH & Co. KG Aumastr. 1 D-79379 Muellheim Tel +49 7631-809-0 Fax +49 7631-809-1250 riester@auma.com AUMA subsidiaries or representatives are implanted in more than 70 countries. For detailed contact information, please refer to our website. www.auma.com Subject to changes without notice. The product features and technical data provided do not express or imply any warranty. Y006.474/003/en/1.14

Open the catalog to page 8All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

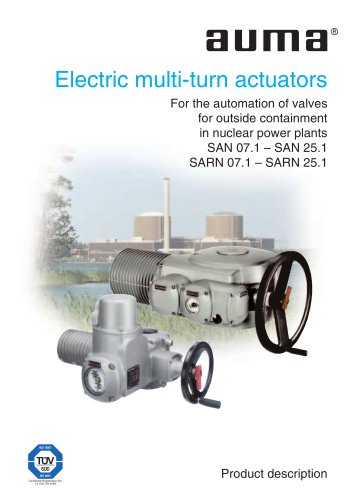

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages