Website:

AUMA

Website:

AUMA

Group: AUMA

Catalog excerpts

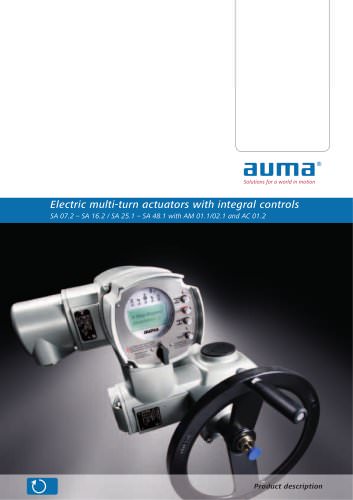

Electric multi-turn actuators with integral controls SA 07.2 – SA 16.2 / SA 25.1 – SA 48.1 with AM 01.1/02.1 and AC 01.2 Product description

Open the catalog to page 1

The actuator specialist AUMA are one of the leading manufacturers of electric actuators, actuator controls and valve gearboxes for the automation of industrial valves worldwide. AUMA have more than 45 years of experience in research & development and manufacture of electric multi-turn and part-turn actuators. AUMA manufacture their products in the two German plants, Muellheim and Ostfildern. Three Service Centers, respectively in Cologne, Magdeburg and Munich, have been set up to offer service support. 2,200 employees belong to the AUMA group worldwide. AUMA automate valves AUMA actuators...

Open the catalog to page 2

The actuator specialist 2 Design principle 30 Applications 4 Interfaces - Valve and electrical connection 33 Large torque range 5 Electromechanical control unit 34 AUMA Generation .2 - Electronic control unit 35 New electric multi-turn actuators and actuator controls 7 Particu|ar conditions - Local adaptations possible! 36 Service conditions 8 Safe and reliable - in any circumstance 37 Basics - Main functions of actuators 11 Prevention, service life, maintenance - Basics - Controls concepts 12 Complete with test engineering features 38 Integration within the DCS - Technical data 40 Actuator...

Open the catalog to page 3

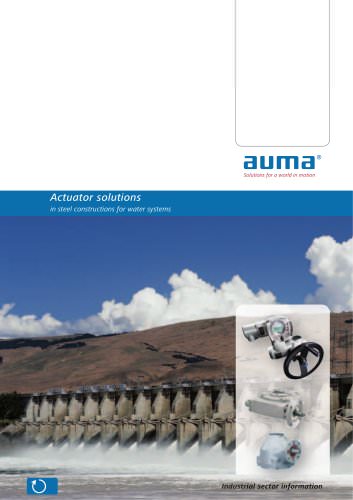

Applications Power : Conventional power plants (coal, gas, oil) : Hydroelectric power plants : Geothermal power plants : Solar thermal power plants : Bio gas power stations Water sector : : : : : Sewage treatment plants Water treatment plants Drinking water distribution Seawater desalination Steel construction for water systems Explosion-proof actuators for use in petrochemical and oil/gas installations and actuators for use in nuclear applications are described in separate brochures. 4 | Industrial and special solutions : : : : : : : : Air conditioning Food industry Chemical/pharmaceutical...

Open the catalog to page 4

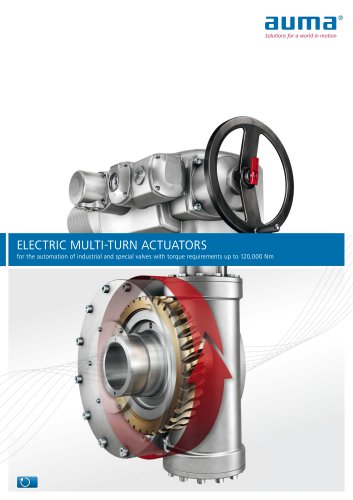

The AUMA SA multi-turn actuators cover a torque range between 10 Nm and 32,000 Nm. In combination with GS part-turn gearboxes, torques up to 675,000 Nm can be achieved. This large torque range ensures that AUMA products are suitable to automate valves of various sizes and pressure levels within any plant. All actuators are integrated into the DCS using a standardised control technology. [1] [1] Multi-turn actuator SA 07.2 Torque range 10 Nm – 30 Nm ■ [2] Multi-turn actuator SA 35.1 with part-turn gearbox GS 630.3 ■ Torques up to 675,000 Nm [2] Large torque range |5

Open the catalog to page 5

AUMA Generation .2 - New electric multi-turn actuators and actuator AUMA actuators and actuator controls are widely used in process plants throughout the world. Their highly developed technology and proven reliability guarantee accurate long-term performance in a wide variety of applications. Generation .2 represents a significant development for the increasing demands in all types of process plants, from the water industry and energy sector to the oil and gas industry. The modular structure provides the perfect combination of multi-turn actuators and appropriate actuator controls. Using...

Open the catalog to page 6

controls Improved handling and operation The user friendliness for Generation .2 actuators was enhanced. ■ The improved AUMA handwheel activation allows single-handed handwheel operation and valve position adjustment by applying minimal force. Activation of manual operation can be signalled to the control room. ■ The AUMA motor plug/socket connection is now available throughout the complete Generation .2 series. ■ One single adjustable reduction gearing set within the control unit for all conventional stroke ranges Precision and control accuracy An improved mechanical structure and reduced...

Open the catalog to page 7

AUMA actuators are used worldwide; in all climate zones, in industrial plants of all kinds under special local ambient conditions. AUMA devices have to operate reliably and for a long time under any conditions without requiring major maintenance work. For this reason, AUMA have focussed on making AUMA devices resistant to the most unfavourable conditions and has adapted protective measures to the state-of-the-art technology. Service conditions AUMA actuators in a Chilean copper mine 8 | Enclosure protection IP 68 AUMA devices of Generation .2 are supplied with improved enclosure protection...

Open the catalog to page 8

Corrosion protection Colour Efficient corrosion protection is a major factor in the guarantee of a long operating life. For the individual parts, the AUMA corrosion protection system is based on a chemical preliminary treatment, followed by a two-layer powder coating. In compliance with the corrosivity categories according to EN ISO 12944-2, various AUMA corrosion protection levels are provided to suit the different applications. The standard colour is silver-grey (similar to RAL 7037). Other colours are possible on request. AUMA Corrosion Classication of environments according to EN ISO...

Open the catalog to page 9

Open-close and modulating duty Valves are subdivided as shut-off valves and modulating valves. ■ In general, shut-off valves are either open or closed. They are rarely operated; when operated, they cover the complete stroke. The time difference between two travels can amount to minutes or even to months. They are controlled by means of the binary signals OPEN and CLOSE. This type of duty is classified as open-close duty. ■ Modulating valves are used to set a default variable being constantly verified and adjusted at short intervals. Control takes place by means of a continuous setpoint,...

Open the catalog to page 10

Switching off in the end positions Protective functions Irrespective of whether the actuator is operated in open-close or modulating duty, the device must automatically switch off when reaching an end position. Two different switch-off mechanisms are available and are applied depending on the type of valve. If an excessive torque is applied during travel, e.g. due to a trapped object within the valve, the controls switch off the actuator to protect the valve. ■ Thermal motor protection Limit seating As soon as the preset switching point in one end position is reached, the controls...

Open the catalog to page 11All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

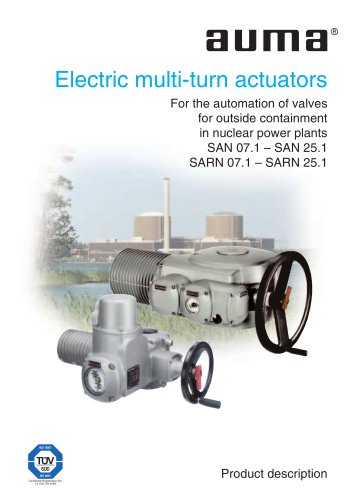

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

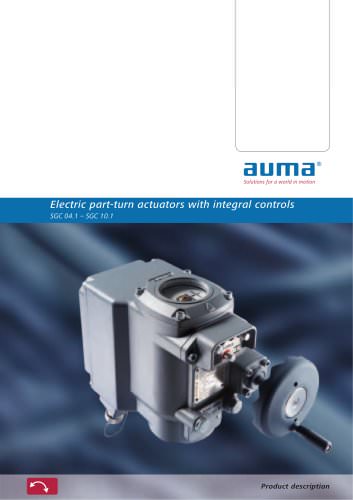

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages