Catalog excerpts

ELECTRIC ACTUATORS for valve automation in nuclear power plants

Open the catalog to page 1

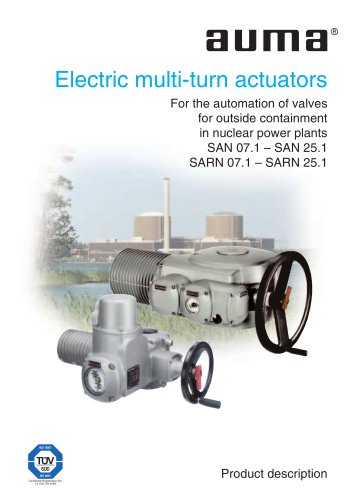

ABOUT THIS BROCHURE This brochure intends to describe functions and possible applications for AUMA actuators qualified for use in nuclear power plants. They include multi-turn actuators for use Outside Containment and Inside Containment and their complementary gearbox series. The document provides an introduction into the issue, an overview on products and well-founded explanations regarding design and function of the devices. In the rear section of this brochure you will find a comprehensive chapter including technical data for simple, initial product selection. For device selection,...

Open the catalog to page 2

Who are AUMA? About this brochure 2 AUMA - the specialist for electric actuators 4 Basics What is an electric actuator? 8 Multi-turn actuators and part-turn actuators 10 AUMA actuators and valve gearboxes for use in nuclear power plants 12 Service conditions during normal operation 14 Service conditions under DBE conditions - Inside Containment 16 Service conditions under DBE conditions - Outside Containment 18 Basic actuator functions 20 Design SAI and SAN Uniform design principle across all sizes 22 Combinations Multi-turn actuator - Part-turn gearbox...

Open the catalog to page 3

AUMA - THE SPECIALIST FOR ELECTRIC ACTUATORS Armaturen- Und MaschinenAntriebe - AUMA - are one of the leading manufacturers worldwide of electric actuators for automating industrial valves. Since 1964, the founding year of the company, AUMA have focussed on development, manufacture, sales and service of electric actuators. The brand AUMA is synonym to long-standing experience and knowledge. Thousands of AUMA actuators are used in safety relevant areas in about 100 nuclear power plants around the globe. As an independent partner of the international valve industry, AUMA supply...

Open the catalog to page 4

Innovation on a day-to-day-business As specialist for electric actuators, AUMA set the market standard for innovation and sustainability. Within the framework of continual improvement, their own in-house vertical range of manufacture guarantee implementation on both product or sub-assembly level. Selecting AUMA: >> provides valve automation in compliance with submitted specifications >> assures safety for design and implementation for plant engineering on the basis of certified interfaces >> guarantees the operator global service on site including commissioning, comprehensive support, and...

Open the catalog to page 5

WORLDWIDE USE Handling radioactive substances requires utmost safety to avoid hazards for persons, environment, and installations. Hardly any other industry is as demanding as the nuclear power industry when it comes to selecting their suppliers. AUMA's listing as approved vendor for decades speaks for itself. National and international approvals The nuclear industry is acting on a global scale. Prior to using a field device in nuclear power plants, the certification process of the respective country must be completed. All AUMA actuator type ranges intended for use in nuclear power plants...

Open the catalog to page 6

Argentina > Atucha 2 Belgium > Doel > Tihange Bulgaria > Kozloduy China > Fangjiashan > Fuquing > Hainan > Tianwan > Qinshan > Taishan Finland > Loviisa 1 + 2 > Olkiluoto 1 + 2 > Olkiluoto 3 France > Flamanville 3 Germany > Biblis > Grafenrheinfeld > Gundremmingen > Krummel > Munchen-Garching > Neckarwestheim > Philippsburg > Unterweser Canada > Darlington Lithuania > Ignalina The Netherlands > Borssele > Petten Research Center Nuclear Russia > Beloyarsk > Kalinin > Kola > Leningrad > Nowoworonesch > Rostow Sweden > Barseback > Forsmark I/II/III > Oskarshamn > Ringhals Switzerland >...

Open the catalog to page 7

WHAT IS AN ELECTRIC ACTUATOR? In nuclear power plants, water - as liquid or vapour - is transported through pipework at high pressure. Industrial valves are used to inhibit or release medium flow as well as to control the resulting flow rate by opening or closing the valves. AUMA actuators are remotely controlled from the control room to operate valves. Automating industrial valves Modern industrial applications are based on a high level of valve automation. This is the requirement for managing complex processes. The actuator positions the valve in compliance with operation commands issued...

Open the catalog to page 8

Requirement for diversity Process engineering plants with pipe systems and valve automation are required all around the globe. Not only types of plants and valves are crucial factors for electric actuators but also the specific conditions in which they are operated. AUMA actuators guarantee reliable and safe service under the most extreme conditions. International test authorities confirm the quality of AUMA actuators designed, manufactured, and tested to customer specifications by issuing product certificates. Requirement for reliability Process engineering plants are only efficient,...

Open the catalog to page 9

MULTI-TURN ACTUATORS AND PART-TURN ACTUATORS The actuation mode is considered a significant distinction factor between the different valve types. A typical example of multi-turn valves are gate valves. They require a defined number of turns at valve input for a complete valve stroke from CLOSED to OPEN and vice versa. Butterfly valves or ball valves are typically used for part-turn movements up to 90°. Globe valves are normally operated via linear movement. Furthermore, certain valves are operated via lever arrangements. In this case, we are talking about lever movement. Specific types of...

Open the catalog to page 10

SAI and SAN multi-turn actuators In compliance with EN ISO 5210, a multi-turn actuator is capable of withstanding thrust applied to the valve and transmits torque to the valve for at least one revolution. In general, multi-turn actuators are required to perform more than one revolution. Consequently gate valves are often equipped with rising valve stems. Therefore, the SAI and SAN multi-turn actuator is equipped with a hollow shaft housing the gate valve stem for these applications. SAI or SAN multi-turn actuators with mounted GSTI multi-turn gearboxes Multi-turn actuators with higher...

Open the catalog to page 11All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

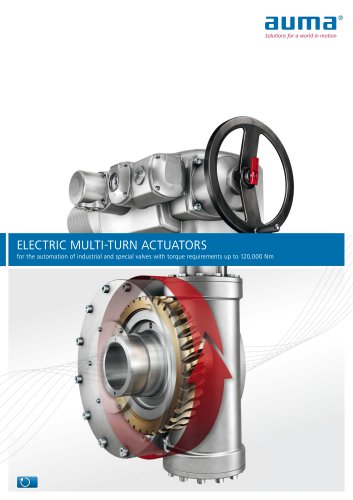

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

Electric part-turn actuators

4 Pages

-

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages