Catalog excerpts

auma Solutions for Qworid in motion Electric actuators with fieldbus interface

Open the catalog to page 1

AUMA is one ol the leading manufacturer* of electric actuators, actuator controls and valve gearboxes for the automatlon of Industrial valves. AUMA has more than 45 years of exprience in research 6 development and in manufacturing electric multi-turn and part-turn actua-tors. AUMA manufactures in two German factories. Three Service Centers, respectively in Cologne, Magdeburg and Munich, have been set up to offer service support. Worldwide 2(2O0 employ魩es belong to the AUMA group. AUMA automates valves AUMA actuators have stand up to a multitude of com-plex requlrements and operate m the...

Open the catalog to page 2

Table ol contents The actuator specialist 2 Applications 4 Modular design - flexible applications S General fieldbus Information 6 General fieldbus information - device intgration 10 Profibus DP 12 Modbus RTU 14 DeviceNet 16 Foundation Fieldbus 18 AUMA actuators with fieldbus interfaces 20 SIMA: leldbus master and actuators from a single source 24 AUMA presales 6 after-sales 26 Links & literature 27 Certificat es 28 Quality is not |ust a matter of trust 29 AUMA Worldwide 30 Solutions for a world in motion This brochure is intended for project engineers and purchasing managers who would like...

Open the catalog to page 3

Power : Conventional power plants (coal, gas, oil) : Hydroelectric power plants : Geothermal power plants : Solar thermal power plants : Biogas power plants Oil & gas : Exploration, offshore plants : Refineries : Distribution : Gas tanks : Tank farms Water sector : Sewage treatment plants : Water treatment plants : Drinking water distribution : Seawater desalination : Steel construction for water resources Industrial and spcial solutions: : Air conditioning : Food industry : Chemical/pharmaceutical industry : Vessel and submarine shipbuilding : Steel mills : Paper industry : Cement works...

Open the catalog to page 4

Individual solutions for individual challenges There is no such thing as a standard actuator, even if most processes appear to be standardised. Because all industrial processes have their own specific particularities. Therefore, AUMA always produces individually cus-tomised solutions and only manufactures upon receipt of order. The multitude of existing valve types, Distributed Control Systems, application conditions and standards call for flexible actuator and controls solutions. Always tailor-made to suit the appropriate application whilst respecting customer demands. Modular design...

Open the catalog to page 5

A fieldbus is an industrial communication system, Connecting a variety of field devices such as trans-ducers (sensors), MOVs and actuators (drives) with a control system. Fieldbus technology was developed in the 1980s to replace the parallel wiring of binary signals, which was common at that time, as well as analogue sigͭnal transmission by digital transmission technology. Today, many different fieldbus systems with different characteris-tics have become established on the market, e.g. Profibus, Interbus, ControlNet, or CAN. Since 1999, fieldbus systems worldwide have been standardised...

Open the catalog to page 6

The fieldbus replaces the parallel trunk groups by a single bus cable and connects all levels, from the field to the process control level. Whatever the automation device, e.g. programmable logic controls (PLC) from different manufacturers or computer-based controls, the fieldbus transmission medium links all components. The devices can be located anywhere in the field. Fieldbus therefore provides a powerful communication network for state-of-the-art modernisation concepts. Digital transmission Only digital information is transmitted in fieldbus systems. Analogue setpoints or measured...

Open the catalog to page 7

Fieldbus systems have many advantages compared to parallel wiring Reduced wiring saves time during planning and installation. ■ Cables, marshalling rack and dimensions of the control cabinet will be reduced. ■ Reducing the components reduces the documentation at the same time. ■ More information can be transferred using fewer wires. ■ Self-diagnosis of the devices via fieldbus reduces downtimes and maintenance times (asset manageͭment). ■ Digitalisation of analogue values improves the protection against disturbance of signals. ■ Digitally collected measurement values and digitally generated...

Open the catalog to page 8

Fieldbus cables/installation Cable types Data transmission via fieldbus cannot be implemented on any cable. Cable types are specified for each fieldbus system. Due to the low data transmission rate, the requirements for Foundation Fieldbus are comparatively low; DeviceNet requires more complex cables as the bus specification requires a separate supply voltage within the same cable. Installation Data transmission on fieldbus systems are performed with low signal levels, e.g. +/- 5 V. The installation has to be performed thoroughly to ensure fault-free data transmission. This applies to...

Open the catalog to page 9

The further development of fieldbus protocols and the increasingly intelligent field devices provide the framework for a variety of additional bus-supported functionalities. This includes simplified device integration, remote pro-gramming and diagnosis of all connected devices by the bus itself via a central computer. Commissioning Contrary to conventional wiring where different signals do not interfere with each other and do not require a chronological order, fieldbus devices have to adhere to strict organisation principles to ensure fault-free communication via the common data...

Open the catalog to page 10

During opration In addition to the central dlimitation of communication parameters, field device configuration can be influenced online: the process behaviour, e.g. of an actuator, can be changed from the control room. The operating behaviour of the field devices can be optimised during operation without gaining access to the device. At the same time, diagnostic information is available, helping to optimise the device parameters with regards to an extended lifetime or enabling more efficient maintenance. The remote parameter setting is only possible if the fieldbus supports the...

Open the catalog to page 11All AUMA catalogs and technical brochures

-

ELECTRIC ACTUATORS

6 Pages

-

Multi-turn actuators

92 Pages

-

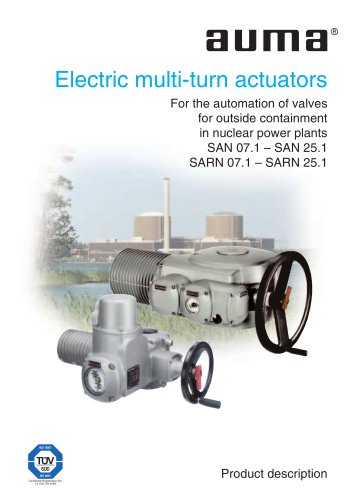

Electric multi-turn actuators

40 Pages

-

SAEx 07.2

1 Pages

-

FUNCTIONAL SAFETY – SIL

28 Pages

-

Service Worldwide

8 Pages

-

SIMA² Master Station

6 Pages

-

AUMA Cloud + AUMA Assistant App

14 Pages

-

AUMA Support App

4 Pages

-

electric actuators

56 Pages

-

FUNCTIONAL SAFETY SIL

28 Pages

-

Service world wide

12 Pages

-

Explosions proof actuators

24 Pages

-

The Actuator Specialist

32 Pages

Archived catalogs

-

Test bench PV 1405

24 Pages

-

Service device PV 788 B

4 Pages

-

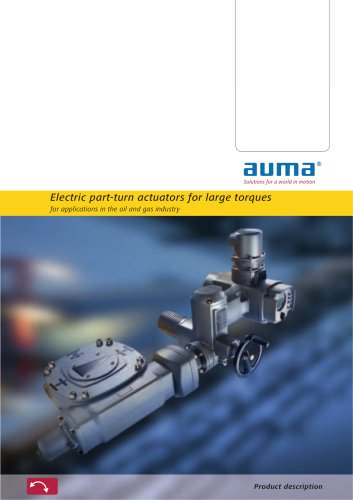

Electric part-turn actuators

4 Pages

-

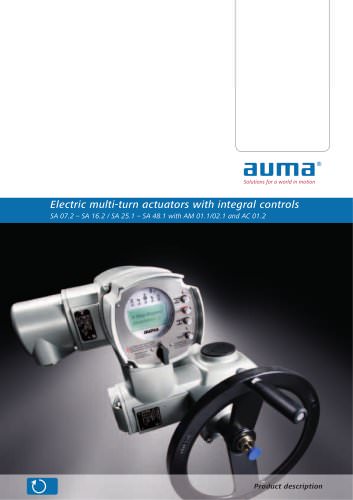

Electric multi-turn actuators

28 Pages

-

Electric multi-turn actuators

24 Pages

-

Multi-turn gearbox GHT 360.1

4 Pages

-

Master station SIMA

4 Pages