Website:

ATMI

Website:

ATMI

Catalog excerpts

The Specialist Manufacturer of Float and Tilt level switches

Open the catalog to page 1

ATMI in a few words A French owned company 100% French manufacturing 40 years of experience on the international market The specialist manufacturer of float and tilt level switches, offering a unique range in the world. A distribution network in more than 150 countries More than 350 distributors specialized in the water and solid industries. International certifications

Open the catalog to page 2

Our range of Float Level Switches

Open the catalog to page 4

Why choose ATMI float level switches? (1/3) 1- Product performance High quality manufacturing - Guarantee of more than 600 000 switching cycles - 3x1 mm² cables with flexibility and elasticity! - 100% French manufacturing - Thanks to their particular shape, no clogging risks! - Multidirectional operation - Thanks to the choice of specific external ballasts, Precise operation ATMI float switches can work in various densities! - No jerking of the pump’s engine guaranteed ! Protection of the pump’s engine thanks to the wide-angle float switch models for turbulent liquids - Record product life...

Open the catalog to page 5

Why choose ATMI float level switches? (2/3) 2- Choice and flexibility for our customers A wide range of level switches to choose from - For every specific need, you have a suitable float switch. Please refer to our “Selection Guide” on Page 9 - PVC: economical cable - Neoprene: for a standard use - HR HY: High Resistant material for longer life (ATMI’s exclusive cable!) - EPDM: sanitary cable Choice of cable type Choice of cable length Product Customization - Standard cable lengths & - Customer-tailored cable lengths - Customizable colors - Customizable branding - Customizable packaging

Open the catalog to page 6

Why choose our liquid float level switches? (3/3) Main advantages of external ballasts: « Clip » ballast Removable ballast Charged resin ballast Plastic Ballast Stainless steel ballast They fix the rotation point of the float switch They allow the float switch to work in a wide range of densities * They are easily adjustable on the cable They allow the float switch to adapt to eventual liquid turbulences They ensure a very accurate level measurement ! * For higher densities, other than the ones indicated on the technical data sheets, additional ballasts should be installed.

Open the catalog to page 7

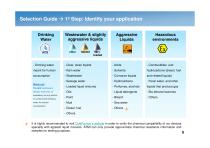

Selection Guide Drinking Water 1º Step: Identify your application Wastewater & slightly aggressive liquids clear Aggressive Liquids Hazardous environments very loaded - Drinking water - Clear, clean liquids - Rain water hydrocarbons (diesel, fuel - Corrosive liquids - Sewage water - Fecal water, and other - Loaded liquid mixtures - Perfumes, alcohols liquids that produce gas - Liquid detergents - Bio-ethanol factories - Diesel, fuel Watch out ! The ACS Certificate of Sanitary Confomity is mandatory for any device in contact with drinking water for human consomption - Others It is highly...

Open the catalog to page 8

Selection Guide 2º Step: Find your Float Switch Devices types Approximate switching differential Click on the photo of the float switch in order to access its product description Cut-out power Wastewater & slightly aggressive liquids Clear Drinking water SOBA / SOBA Small AQUA PLUS (lest externe) AQUA XL / Medium Very loaded (lest interne) Aggressive Liquids Hazardous Environments

Open the catalog to page 9

SOBA EP, ACS certified: For drinking water Advantages ACS certified device for drinking water applications Ecological float switch (no mercury, no lead) Switching angle : +/- 25º Maximum pressure : 3,5 bars Cut-out power : 16 (6) A (16A resistive – 6A inductive) Allowed fluid density : From 0.70 to 1.15 ACS Sanitary Certification in compliance with the AFNOR XP P41-250 (1-2-3) standard Applications Drinking water for human consumption Level control of multiple pumps Emptying / Filling function Overflow or dry-running protection High / low level alarm Selection guide

Open the catalog to page 10

ATS 165 EP, ACS certified: For agitated drinking water Advantages ACS certified device for drinking water for human consumption +/-165º switching angle that protects the pump's engine from jerking Switching angle : +/- 165º Maximum pressure : 3,5 bars Cut-out power : 20 (8) A (20A resistive – 8A inductive) Allowed fluid density : From 0.70 to1.10 ACS Sanitary Certification in compliance with the AFNOR XP P41-250 (1-2-3) standard Drinking water for human consumption Emptying / Filling function Overflow or dry-running protection High / low level alarm Selection guide

Open the catalog to page 11

AQUA PLUS: For clear / heavily loaded Advantages Economical device, easy to use, easy to install Small size float switch, ideal for restricted-space applications 140 mm Technical characteristics Switching angle : +/- 95º Maximum pressure : 3,5 bars Cut-out power : 16 (6) A (16A resistive – 6A inductive) Allowed fluid density : From 0.85 to 1.20 Applications Clear, clean liquids, rain water, wastewater, sewage water, charged liquids and slightly aggressive liquids Level control of multiple pumps Emptying / Filling function Overflow or dry-running protection / High - low level alarm Selection...

Open the catalog to page 12

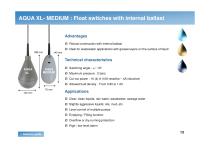

AQUA XL- MEDIUM : Float switches with internal ballast Advantages Robust construction with internal ballast Ideal for wastewater applications with grease layers on the surface of liquid 165 mm Technical characteristics AQUA XL AQUA MEDIUM Switching angle : +/- 10º Maximum pressure : 2 bars Cut-out power : 10 (4) A (10A resistive – 4A inductive) Allowed fluid density : From 0.95 to 1.05 Applications Clear, clean liquids, rain water, wastewater, sewage water Slightly aggressive liquids: oils, mud, etc. Level control of multiple pumps Emptying / Filling function Overflow or dry-running...

Open the catalog to page 13

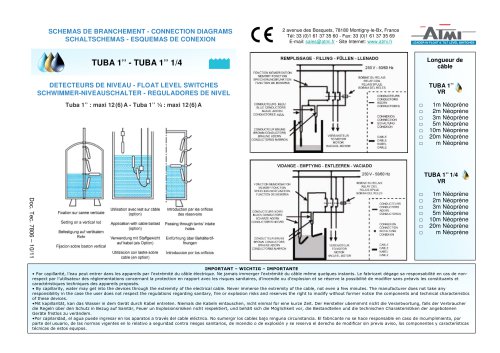

TUBA 1’’ and 1’’¼ : Small diameter float switches Advantages Installation possible up to 55 meters of water depth Small diameter, ideal for narrow-access tanks and reduced spaces Switching angle : +/- 20º Maximum pressure : 5,5 bars 1’’ Cut-out power : 12 (6) A (12A resistive – 6A inductive) Allowed fluid density : From 0.70 to 1.50 Applications Clear, clean liquids, rain water 36 mm 29 mm Slightly aggressive liquids: oils, mud, fuel, paint, etc. Level control of multiple pumps Emptying / Filling function Overflow or dry-running protection / High - low level alarm Selection guide

Open the catalog to page 14All ATMI catalogs and technical brochures

-

ATMI product catalog

12 Pages

-

PULSE ISOLATOR

4 Pages

-

SOLIBA PRA

2 Pages

-

SOLIBA PRP

2 Pages

-

SOLIBA M

2 Pages

-

SOLIBA Msmall

2 Pages

-

FIX-CAB

1 Pages

-

PIEZO ST

1 Pages

-

ATMI range of products

1 Pages

-

Cable clamps

1 Pages

-

AQUA MEDIUM

2 Pages

-

Metal case for SOLIBA

2 Pages

-

TUBA 125C

2 Pages

-

SOLIBA EX GP

2 Pages

-

SOLIBA EX P

2 Pages

-

SOLIBA

2 Pages

-

AQUA MEDIUM EP

2 Pages

-

BIP STOP

2 Pages

-

AQUA XL

2 Pages

-

SOBA HR HY

2 Pages

-

SOBA SMALL

2 Pages

-

PIEZO AS

1 Pages

-

SOLIBA SPECIAL

1 Pages

-

CABLE CLAMP

1 Pages

-

Wiring diagrams - TUBA

1 Pages

-

Wiring diagrams - SOBA

1 Pages

-

Wiring diagrams - BIP ECO

1 Pages

-

Wiring diagrams - AQUA PLUS

1 Pages

-

CE Declaration of conformity

1 Pages

-

Certificate ISO 9001 - 2008

1 Pages

-

ATEX Certificate

4 Pages

-

ACS Certificate

1 Pages

-

Range for solid (Power Point)

20 Pages

-

Intrinsically safe relays

2 Pages

-

Data sheet - Regulasonde

2 Pages

-

ATMI Competitive Advantage

1 Pages

Archived catalogs

-

ATMI Brochure

6 Pages