Catalog excerpts

ATLAS COPCO AIR MOTORS A full range of compact, high performance air motors

Open the catalog to page 1

AIR MOTOR FEATURES AND CHARACTERISTICS • Air motors are compact and lightweight. An air motor weighs only a quarter as much and occupies only one sixth of the space of an electric motor of equivalent output power. Air motors develop far more power relative to size and weight than most other motor types. Our air motors are explosion proof certified, in compliance with the European Union´s ATEX directive 94/9/EC. For equipment used in potentially explosive environments. • Air motors can be stalled indefinitely without overheating or sustaining any other damage. They can be started and stopped...

Open the catalog to page 2

ADDITIONAL INFORMATION ABOUT AIR MOTORS FROM ATLAS COPCO Guide Pocket tors Air Mo CONTENTS Introducing the air motor • Methods of modifying motor output Choosing your motor • • • • • • • • • The working point Atlas Copco air motor selection guide Starting torque and stall torque Accelerating a load to speed Shaft loading Silencing Temperature Hostile environments Atlas Copco air motor selection program Installing your air motor Selecting the right motor has never been easier! Just enter the required working point for the application and the most suitable motor will automatically be...

Open the catalog to page 3

It should be noted that all vane air motors produce a variable starting torque, due to the position of the vanes in the motor when it is started. The variation differs between motor types and must be checked on an individual basis. The air motor is one of the toughest and most The power that an air motor produces is a function of torque and speed. All ungoverned air motors produce the same characteristic power curve, with maximum power occurring at around 50% of the free speed. The torque produced at this point is often referred to as ”torque at maximum output.” versatile power units...

Open the catalog to page 4

CHOOSING YOUR MOTOR Desired working point Torque with standard motor at 6.3 bar (91 psi) Torque with throttled motor Torque with pressure regulator Speed [r/min] Hostile environments Starting torque and stall torque Acidic – Explosive – Radioactive – High temperature – Moist – Dusty – Intense electric fields – Underwater – High humidity. Other applications require a certain stall torque. A motor’s stall torque can be calculated by looking up the ”torque at maximum output“ and multiplying this value by two. Where it is desirable to control the stall torque, the technique of pressure...

Open the catalog to page 5

INSTALLING YOUR AIR MOTOR Air lines The recommended dimensions of air lines are given in the introductory section to each motor type. Note that exhaust hose is larger than inlet hose. The recommendations are valid for hose lengths of up to 3 meters. For distances between 3 and 15 meters select a hose diameter one size up, and for distances between 15 and 50 meters select a hose diameter two sizes up. It is important to note that the output of the motor will be reduced if these guidelines are not followed. Recommended hose connectors Because of the compact dimensions of Atlas Copco vane...

Open the catalog to page 6

INTRODUCTION TO ATLAS COPCO AIR MOTORS AND GEAR UNITS Lubrication free air motors Atlas Copco’s lubrication free air motors are equipped with low-friction vanes, sealed bearings and vented cylinder plates. Since they release no lubricants into the air, they offer a viable drive solution for sensitive processes and hygienic environments where oil contamination would be at best a problem and, at worst, a catastrophe. LZL vane motors – 1.05 kW to 6.5 kW Type LZL Atlas Copco vane motors have been designed to offer outstanding starting and low speed performance. These general purpose motors are...

Open the catalog to page 7

VANE MOTORS

Open the catalog to page 8

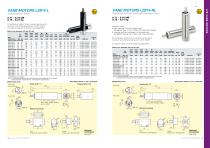

Mounting Type LZB vane motors may be mounted in any position. To facilitate this, flange and foot mounting are available for each motor, Figure 15. LZB vane motors are designed to provide high performance and high standards of reliability. They are characterized by high power output and small physical size, Figure 12. Reversible Motor The compressed air supply should be connected to the inlet that gives the desired direction of rotation, Figure 17. The inlet not in use functions as an additional outlet: it must not be plugged. The design of the motor is long and slim. This gives a number of...

Open the catalog to page 9

Stainless steel and lubrication free Lubrication free EX certification valid for fixture mounted use only with a maximum surrounding temperature of +40°C (104°F). For optional vanes and accessories see pages 66-67. Material in parts: • back head and front part stainless steel: ISO 683/XIII Type 17, SS 14 2346, DIN 17440 X12CrNiS188 • outgoing shaft and casing/gear rim stainless steel: ISO 683/XIII Type 9b, SS 14 2321, DIN 17440 X22CrNi17 Stall torque Air Free consumption speed at max output Shaft loading [kg] [lb] code 1) ATEX code 1) For Shaft loading curves, see page 16. NOTE: - If...

Open the catalog to page 10

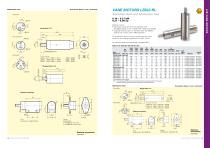

Lubrication free LZB14-L: Performance curves at air pressure 6.3 bar (91 psi) 0.16 – 0.27 kW 0.21 – 0.36 hp EX certification valid for fixture mounted use only with a maximum surrounding temperature of +40°C (104°F). For optional vanes and accessories see pages 66-67. Data at air pressure 6.3 bar (91 psi) Max output Min starting Stall torque torque Stall torque Air Free consumption speed at max output Shaft loading [kg] [lb] code 1) ATEX code 1) For Shaft loading curves, see page 16. NOTE: - If running motors with 100% dry air and no lubrication, performance can be reduced with 5-15% at max...

Open the catalog to page 11

Conversion factor 1 mm = 0.04 inch Stainless steel and lubrication free 0.16 – 0.27 kW 0.21 – 0.36 hp Material in parts: • back head, casing and front part stainless steel: ISO 683/XIII Type 17, SS 14 2346, DIN 17440 X12CrNiS188 • outgoing shaft and gear rim stainless steel: ISO 683/XIII Type 9b, SS 14 2321, DIN 17440 X22CrNi17 EX certification valid for fixture mounted use only with a maximum surrounding temperature of +40°C (104°F). For optional vanes and accessories see pages 66-67. Min starting Stall torque torque Stall torque Air Free consumption speed at max output Shaft loading [kg]...

Open the catalog to page 12All Atlas Copco Compressors catalogs and technical brochures

-

LZ OIL-FREE COMPRESSOR

5 Pages

-

Compressed air filters

20 Pages

-

Tensor STBx4

2 Pages

-

BCV – BCP Battery tools

6 Pages

-

Li-Ion battery management

4 Pages

-

BUILDING HEAVY TRUCKS AND BUSES

46 Pages

-

BOLT TIGHTENING SOLUTIONS

18 Pages

-

AEROSPACE INDUSTRIAL SOLUTIONS

128 Pages

-

Hurricane Screw Boosters

2 Pages

-

B18-62

2 Pages

-

Tensor Revo

4 Pages

-

Tensor ES

8 Pages

-

Industrial Power Tools catalogue

173 Pages

-

Atlas Copco Screwdriver Range

52 Pages

-

Tensor SB

2 Pages

-

BCP Battery tools

6 Pages

-

Air Line Accessories catalogue

67 Pages

-

Air & Industrial Gas Compressors

40 Pages

-

EBL Screwdriver

6 Pages

-

Drills

2 Pages

-

Battery Tools

6 Pages

-

Air Motors

76 Pages

-

BD 100 - 3000

8 Pages

Archived catalogs

-

B15-62

2 Pages

-

LBV16M Modular Drill

2 Pages

-

HM Hose Reels

4 Pages