Catalog excerpts

Atlas Copeo Sustainable- ProdvicfiVffiy

Open the catalog to page 1

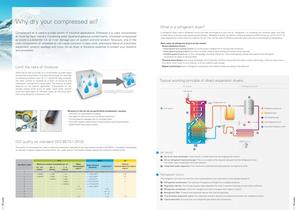

Compressed air is used in a wide variety of industrial applications. Wherever it is used, compressed air must be clean and dry. Containing solid, liquid and gaseous contaminants, untreated compressed air poses a substantial risk as it can damage your air system and end product. Moisture, one of the main components of untreated air can cause corrosion in pipe work, premature failure of pneumatic equipment, product spoilage and more. An air dryer is therefore essential to protect your systems Limit the risks of moisture When the air that surrounds us is compressed, its water vapor and...

Open the catalog to page 2

Atlas Copeo s FD refrigerant dryers Based on years of experience in the industry. Atlas Copeo has chosen to incorporate direct expansion technology with cycling, non-cycling and Variable Speed variants in its range. Direct expansion dryers without Saver Cycle Control (non-cycling) FLOW ■■■■■■■■■■■■■■■■■■ • Applications: stable dewpoint, full load applications. • Key advantage: fixed speed dryers run continuously to ensure a stable dewpoint by design (irrespective of varying load conditions). Direct expansion dryers with Saver Cycle Control (cycling) • Applications: varying temperatures,...

Open the catalog to page 3

FD 5-95 & FD 120-285: Superior productivity 6 Optimum performance and safety in all conditions Hot gas bypass valve prevents freezing at lower loads. R134a piston compressor with high coefficient of performance (FD 5-95) or extremely reliable R410a rotary compressor (FD 120-285) provide the best performance for each size while having minimum environmental impact. Capillary tubes cope with all conditions – no moving parts for extra reliability. FD 120-285 also offer condenser with louvered fin technology for improved performance in dusty environments. 1 Electronic no-loss condensate drain...

Open the catalog to page 4

O High-efficiency heat exchanger • Counter-flow on both air-to-air and air-to-refrigerant sides for efficient heat transfer. As the outgoing air is reheated, it protects the outlet piping against pipe sweating • Unlike some other dryer designs, a separate pre-filter is not required. This results in a low pressure drop. The design ensures a smooth air flow which makes the dryer less sensitive to contamination O Integrated water separator • Low velocity condensate separator with high separation efficiency even in low flow conditions • Reliable and effective condensate evacuation from the...

Open the catalog to page 5

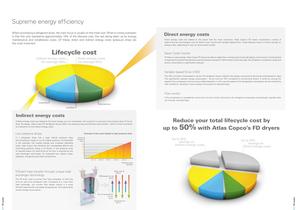

Supreme energy efficiency When purchasing a refrigerant dryer, the main focus is usually on the initial cost. What is mostly overseen is that this only represents approximately 10% of the lifecycle cost, the rest being taken up by energy, maintenance and installations costs. Of these, direct and indirect energy costs (pressure drop) are the most important. Lifecycle cost Indirect energy costs (on average 38%) Direct energy costs Direct energy costs are related to the power that the dryer consumes. Atlas Copco's FD dryers incorporate a variety of state-of-the-art technologies such as Saver...

Open the catalog to page 6

A step ahead in control and monitoring Atlas Copco's Elektronikon® controls and monitors your FD refrigerant dryers to ensure optimal productivity and efficiency at your site. User-friendly interface Available in 32 languages, this graphical 3.5-inch high-definition color display with pictograms and LED indicators for key events is easy to use. The keyboard is durable to resist tough treatment in demanding environments Comprehensive maintenance display Valuable items of information displayed include the ServicePlan indicator and preventive maintenance warnings Internet-based visualization*...

Open the catalog to page 7

Driven by innovation With more than 135 years of innovation and experience, Atlas Copco will deliver the products and services to help maximize your company’s efficiency and productivity. possible cost of ownership. Through continuous innovation, we strive to safeguard your bottom line and bring you peace of mind. Building on interaction As part of our long-term relationship with our customers, we have accumulated extensive knowledge of a wide diversity of processes, needs and objectives. This gives us the flexibility to adapt and efficiently produce customized compressed air solutions that...

Open the catalog to page 9All ATLAS Copco Compressors USA catalogs and technical brochures

-

SCROLL COMPRESSORS SF / SF+

7 Pages

-

LZ OIL-FREE COMPRESSOR

5 Pages

-

TP-Series

2 Pages

-

T-Series

2 Pages

-

H series

2 Pages

-

ZM31 -246

3 Pages

-

T3W Water Well Drill

1 Pages

-

Condensate Management

2 Pages

-

Atlas Copco Portable Air

2 Pages

-

Membrane Nitrogen Generators

2 Pages

-

mVAC-250 ? mVAC-9200

12 Pages

-

P 37 - P 275

12 Pages

-

Brochure GA 11+-30/GA 15-30 VSD

20 Pages

-

Brochure G 110-250

8 Pages

-

Brochure ZH+

16 Pages

-

Brochure ZH 350+

12 Pages

-

Brochure ZS+ VSD

20 Pages

-

Brochure ZS

20 Pages

-

Brochure ZB 5-120 VSD

12 Pages

-

Brochure ZB 100-160 VSD

12 Pages

-

Marine Air Booklet

68 Pages

-

Brochure FX 1-21

5 Pages

-

Brochure OSC/OSD

8 Pages

-

Brochure CD 1-22+

2 Pages

-

Driving Expander Technology

29 Pages

-

MED Breathing and Surgical Air

12 Pages

-

Silicone free Filters

2 Pages

-

Compressed Air Filters

12 Pages

-

FD 5-4000

6 Pages

-

ZB 100-160 VSD 100-160 kW

12 Pages

-

ZR/ZT 55-90 FF & ZR/ZT 90 VSD-FF

22 Pages

-

AQ 30-55/ AQ 37-55 VSD

18 Pages

-

Oil-free Scroll Compressors

12 Pages

-

LFx 0.7-2.0

12 Pages

-

GA 30+-90/GA 37-90 VSD®

16 Pages

-

Atlas Copco Railway compressors

12 Pages

-

GN 4-18 kW/5.5-25 hp

6 Pages

-

GX 2-11

6 Pages

-

XA(M,H)S 500-750

2 Pages

-

XAS 137 XAHS 107

2 Pages

-

HardHat™

6 Pages

-

BD 100-3000

8 Pages