Catalog excerpts

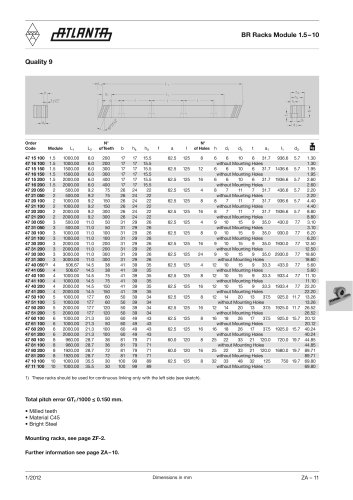

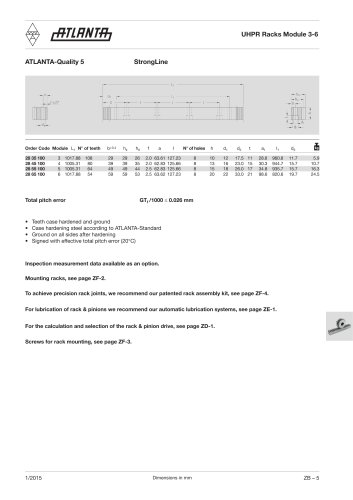

rftTLRNTfh UHPR Racks Module 3-6 Order Code Module L1 N° of teeth b+0’4 hk h0 f a I N° of holes h d1 d2 t a1 I1 d3 Total pitch error • Teeth case hardened and ground • Case hardening steel according to ATLANTA-Standard • Ground on all sides after hardening • Signed with effective total pitch error (20°C) Inspection measurement data available as an option. Mounting racks, see page ZF-2. To achieve precision rack joints, we recommend our patented rack assembly kit, see page ZF-4. For lubrication of rack & pinions we recommend our automatic lubrication systems, see page ZE-1. For the calculation and selection of the rack & pinion drive, see page ZD-1. Screws for rack mounting, see page ZF-3.

Open the catalog to page 1All Atlanta Drive Systems catalogs and technical brochures

-

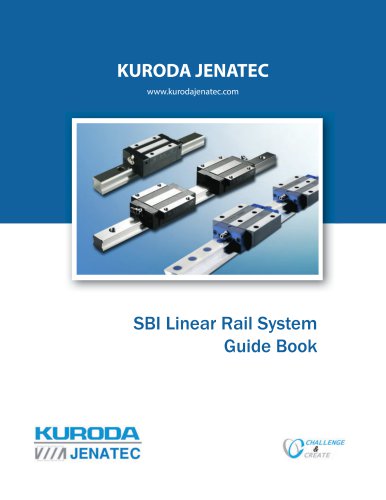

Linear Guideway

118 Pages

-

Linear Rail Systems

63 Pages

-

Right-Angle Bevel Gearboxes

18 Pages

-

ATLANTA Product Overview

12 Pages

-

ATLANTA BG Servo-Bevel Reducers

13 Pages

-

ATLANTA B Servo-Worm Reducers

16 Pages

-

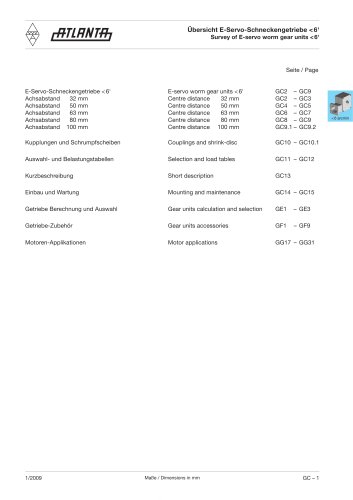

ATLANTA E Servo-Worm Reducers

18 Pages

-

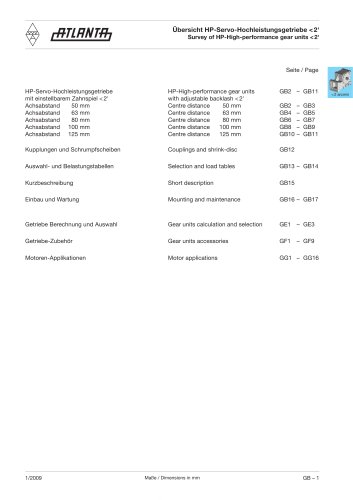

ATLANTA HP Servo-Worm Reducers

17 Pages

-

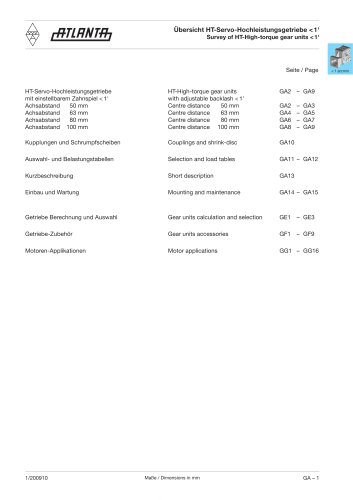

ATLANTA HT Servo-Worm Reducers

15 Pages

-

ATLANTA Pinion Range

40 Pages

-

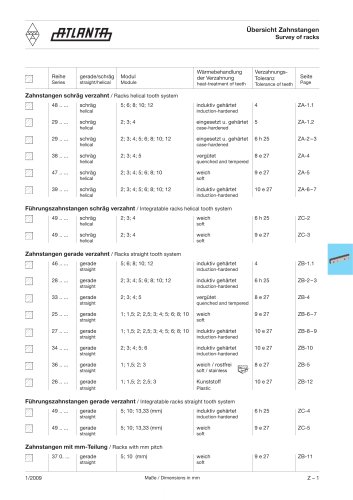

ATLANTA Rack Range

39 Pages