Catalog excerpts

Servo-Drive System ATLANTA Drive Systems Inc. 1775 Route 34, Unit D-10 Farmingdale, NJ 07727 USA Telephone: Fax: E-Mail: Internet: Duplication – even by way of excerpts – is not allowed without our express permission. Dimensions and any other technical details given in this catalogue are subject to alterations without notice and are completely without obligation on our part. All rights to make technical changes to the dimensions and the range of our standard programme are reserved.

Open the catalog to page 1

Tradition. Innovation. Progress. ATLANTA Drive Systems has offered convincing high-quality power transmission solutions for more than 75 years. As a medium-sized company we have specialized in the development, construction and production of high quality drive systems. ATLANTA customers are found in all areas of transmission engineering. The main focus however, lies in machine tool, woodworking machines, robotics and handlings, food machinery, packaging machines, boxing machines and special purpose machines. We are market leaders in high quality racks and define market trends. All components...

Open the catalog to page 2

Order Codes - Examples Example High-Performance Gear Units Gear Units Keyway Design Center Distance High-Performance Shrink-Disk Design Center Distance with Holes Rack Length

Open the catalog to page 4

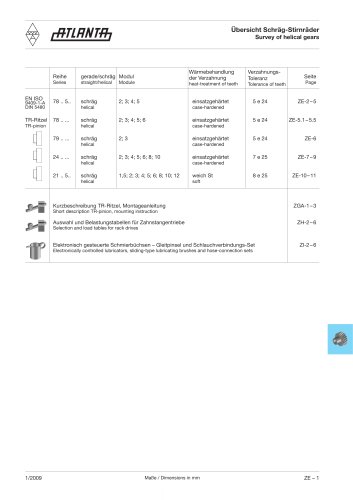

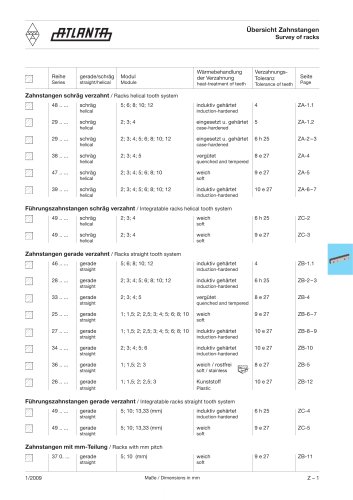

Servo Gearboxes HT High-Torque Gear Units < 11 GA HP High-Performance Gear Units <2' GB E Servo-Worm Gear Units <5' GC B Servo-Worm Gear Units < 12' GD BG Servo-Bevel Gear Units <6' GE Gear Units Calculation and Selection GF Pinion and Output Drive Shafts GG Shrink-Disk Clamping Sets GH Mounting Guide for Servo-Gear-Boxes and Servo Motors Gl Racks and Pinions Helical Tooth System m = 1.5 - 12 ZA Straight Tooth System m = 1 - 12 ZB Integrated Racks for Guides m = 2 - 4 ZC Rack and Pinion Drive - Calculation and Selection ZD

Open the catalog to page 5

Servo Gearbox Family ATLANTA Servo Drive System: Setting Standards for Technological Leadership The world‘s most extensive range of precision racks together with the complete family of servo gear units, provides an unmatched range of combinations to achieve the best solution to almost all possible applications. For each application the right solution: n High-precision Machine Tools, Laser Cutting Plants n Wood-, Plastic- and Aluminium Processing Machines, Machine Tools n Lifting Shafts, Gantries, Handling n Welding Robots, Handling, Control Units Linear Axis of a Woodworking Machine

Open the catalog to page 6

Servo Gearbox Family BG Servo E Servo B Servo Linear Axis with Integrated Lubrication System Driving and Lifting Axis of a Robotic Palletizer

Open the catalog to page 7

Servo Gearbox Family HT High-Torque Gear Units 150 % Output Torque Backlash < 1 arcmin Highest stiffness HP High-Performance Gear Units 100 % Output Torque Backlash < 2 arcmin Highest stiffness E Economy Gear Units 100 % Output Torque Backlash < 5 arcmin Highest stiffness B Basic Gear Units 90 % Output Torque Backlash < 12 arcmin High stiffness BG Servo-Bevel Gear Units 100 % Output Torque Backlash < 6 arcmin Highest stiffness

Open the catalog to page 8

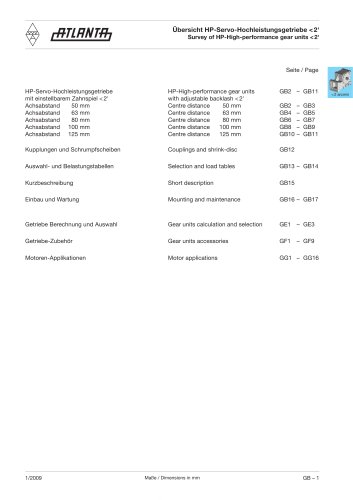

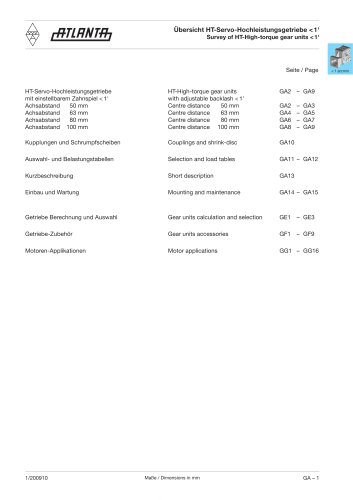

HT High-Torque Gear Units < 1' Page HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance 50 mm Center Distance 63 mm Center Distance 80 mm Center Distance 100 mm Selection and Load Tables Short Description Gear Units Calculation and Selection GF1 – GF3 Gear Units Accessories

Open the catalog to page 9

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Fig. 1 Output Shaft with Interface EN ISO 9409-1-A-40 Fig. 2 Output Shaft for Clamp Connection 80 84 036

Open the catalog to page 10

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Order Code Fig.1 Fig. 2 Ratio i DG7 k Other center distances and ratios on request.

Open the catalog to page 11

HT High-Torque Gear Units with Adjustable Backlash <1' Fig. 1 Output Shaft with Interface EN ISO 9409-1-A-50 Fig. 2 Output Shaft for Clamp Connection 80 85 050

Open the catalog to page 12

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Order Code Fig.1 Fig. 2 Ratio i DG7 k r Other center distances and ratios on request.

Open the catalog to page 13

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Fig. 1 Output Shaft with Interface EN ISO 9409-1-A-63 Fig. 2 Output Shaft for Clamp Connection 80 86 062

Open the catalog to page 14

HT High-Torque Gear Units with Adjustable Backlash <1' Order Code T Jred Other center distances and ratios on request.

Open the catalog to page 15

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Fig. 1 Output Shaft with Interface EN ISO 9409-1-A-80 Fig. 2 Output Shaft for Clamp Connection 80 87 080

Open the catalog to page 16

HT High-Torque Gear Units with Adjustable Backlash < 1' Center Distance Order Code Fig.1 Fig. 2 Ratio i DG7 k r Other center distances and ratios on request.

Open the catalog to page 17

Connecting Elements Special Couplings for Motor/Gear Units, Rigid Model, nitrided, preassembled for Motor Shafts without Key < 1 arcmin Bore on gear unit side low-clearance tooth-hub profile corresponding to DIN 5480 for push-fitting Bore on motor side with locking elements as clamp connection Reference Diameter for Mounting 1) Spare part clamping element Shrink-Disk Clamping Sets for Output Drive Shafts of Gear Series 98 8. ... L1

Open the catalog to page 18

Selection and Load Tables for HT High-Torque Gear Units The values in the tables are based upon wear or maximum flank load at 12,000 hours full load and on servo-operation. With continuous full-load operation it may be necessary to consider temperature limits! (Please ask us, if in doubt.) < 1 arcmin T2max. = static torque to avoid tooth fracture, P1 = driving power in kW, T2 = output torque in Nm. Driving Speed n1 in rpm Order code a0 i T2 max. 500 750 1000 1500 3000 4000 5000 η P1 T2 P1 T2 P1 T2 P1 T2 P1 T2 P1 T2 P1 T2 at (mm) (kw) (Nm) (kw) (Nm) (kw) (Nm) (kw) (Nm) (kw) (Nm) (kw) (Nm)...

Open the catalog to page 19

Selection and Load Tables for HT High-Torque Gear Units Gearing Efficiency of Servo-Worm Gear Units with Driving Worm and under Full Load. Additional Loads on Output Drive The data given are reference values. You should consider the values arising from the choice of the tooth system. It is assumed that the point of action of the force is the center of the shaft. In cases where additional axial forces occur, over and above high transverse forces, please ask for advice. Center Distance Dimensions Center Casing/ EN ISO Clamp EN ISO Clamp EN ISO Clamp EN ISO Clamp CenterTeeth Connect. Connect....

Open the catalog to page 20All Atlanta Drive Systems catalogs and technical brochures

-

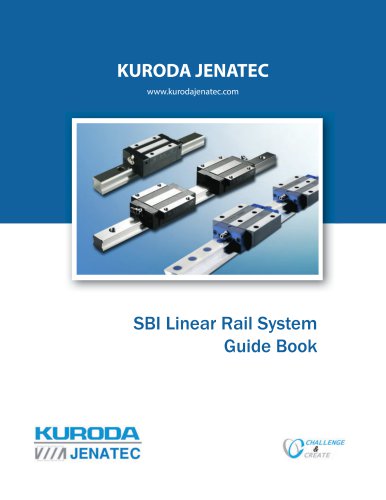

Linear Guideway

118 Pages

-

Linear Rail Systems

63 Pages

-

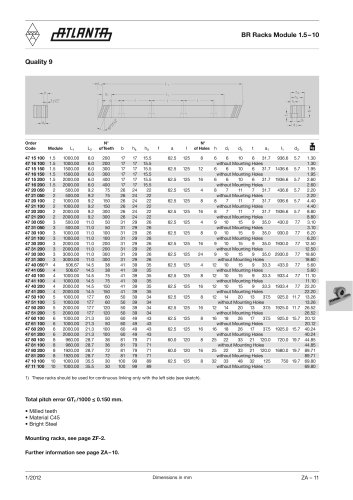

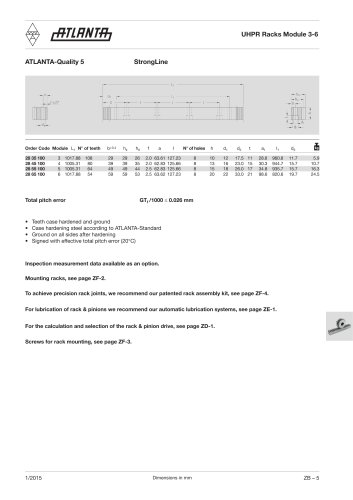

UHPR StrongLine DIN 5 Racks

1 Pages

-

Right-Angle Bevel Gearboxes

18 Pages

-

ATLANTA Product Overview

12 Pages

-

ATLANTA BG Servo-Bevel Reducers

13 Pages

-

ATLANTA B Servo-Worm Reducers

16 Pages

-

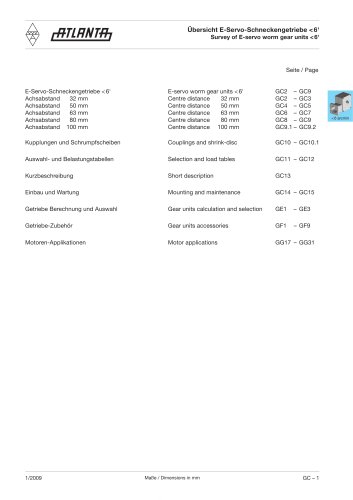

ATLANTA E Servo-Worm Reducers

18 Pages

-

ATLANTA HP Servo-Worm Reducers

17 Pages

-

ATLANTA HT Servo-Worm Reducers

15 Pages

-

ATLANTA Pinion Range

40 Pages

-

ATLANTA Rack Range

39 Pages