Website:

ASYS GROUP

Website:

ASYS GROUP

Group: Asys

Catalog excerpts

MOTUS Linear transfer technology

Open the catalog to page 1

MOTUS Linear transfer technology Modular and flexible Flexible installation – that is our biggest concern. Our standardised individual components are the ideal answer for fully automated, large-scale series production and for hybrid assembly systems, because flexibility is required in both cases. Hybrid systems must have an open design, so that the degree of automation can be adapted to an increase in the number of parts. In turn, there must be retrofitting flexibility for variant assembly in large-scale series production. Designing a transfer system requires the following basic data:...

Open the catalog to page 3

MOTUS Transfer section Transfer sections are typically used for the transport of workpiece carriers. They form the basic element of all transfer solutions, regardless of whether a square or an underfloor system is to be realized. › The drives, including the motor as well as spacers, can be moved freely on the transfer section. The motor can be rotated into three positions. › Section length can be selected flexibly. Features: › Workpiece carrier transport by polyamide conveyor belts using a twin-belt principle. › Stable aluminium conveyor profile with all-side grooves for holding grooved...

Open the catalog to page 4

MOTUS Workpiece carriers Workpiece carriers are used for transporting workpieces to the transfer sections. Another important function is holding workpieces and data carriers. Features: › Anodised aluminium plate for simple attachment of receptacles. › Plastic slide bars for careful, low-wear transport of workpiece carriers and damping of impact noise. › Plastic stop bars for damping workpiece carrier impact and noise. The attachment is used as a switch element for damping the sensor. › Two diagonally arranged centring bushes for the precise positioning of the workpiece carrier. › Safe...

Open the catalog to page 5

MOTUS Stopper Stoppers stop the workpiece carrier on the transfer section – without strict demands on positioning accuracy. The stopper piston is activated and returned pneumatically. Features: › The stopper is inserted with a positive fit into a side groove of the conveyor profile and fastened with a friction fit using two slot nuts. The mounting can be realized on the left or right side of the profile. › The stopper can be used universally for all sizes of MOTUS Stopper, damped workpiece carriers as a stopper or pre-stopper on the front or rear stop bar of the workpiece carrier. › Compact...

Open the catalog to page 6

MOTUS Lifting and indexing unit In the lifting and indexing unit, the workpiece carrier is lifted from the transfer conveyor and positioned precisely for processing against two downholders. Before the vertical pneumatic lifting movement is performed, the workpiece carrier is stopped by a stopper. A sensor detects the presence of the workpiece carrier. After work is complete, the workpiece carrier is lowered onto the conveyor again and moved out from the station. Included: 1 Lifting and indexing unit 1 Set of mounting material on the conveyor profile 1 Set of sensors with holders for lifting...

Open the catalog to page 7

MOTUS Lifting and indexing unit, lockable In the lifting and indexing unit, the workpiece carrier is lifted from the transfer conveyor and positioned for processing with a high load. Before the vertical pneumatic lifting movement is performed, the workpiece carrier is stopped by a stopper. A sensor detects the presence of the workpiece carrier. After work is complete, the workpiece carrier is lowered onto the conveyor again and moves out from the station. Included: 1 Lifting and indexing unit 1 Set of mounting material on the conveyor profile 1 Set of sensors with holders for lifting...

Open the catalog to page 8

How does the workpiece flow continue? The transfer section, workpiece carrier, stopper, and lifting and indexing unit form the core elements of the transfer mechanism. And this is how the workpiece flow continues: With another transfer section in an extension straight ahead. With another transfer section offset by 90° and a 90° curve section. With another transfer section arranged in a different plane and a workpiece carrier lift. With another transfer section arranged parallel and a 180° curve section. With two additional transfer sections each offset by 90° and a bridge that together form...

Open the catalog to page 9

With the help of a 90° curve section – without its own drive – two transfer sections arranged at a right angle to each other can be easily connected. Features: › No separate drive, sensor, or stopper elements, and thus absolutely no expensive control necessary for the curve section. › Workpiece carriers can be moved into jam in the curve section and then accelerated again from the jam mode – in any position. › The workpiece carriers have very high anti- tipping safety; non-centred loading is not critical. Included: 1 Curve section 90° 2 Straight sections 1 U conveyor with drive and mounting...

Open the catalog to page 10

MOTUS Junction unit 90° With this junction unit, workpiece carriers can be fed in/discharged from a main section to a branch section. A simple, pneumatically driven curve segment controls the workpiece carrier flow. Features: › No additional motorised drive for the components necessary. › Workpiece carriers can be moved into jam in the curve section and then accelerated again from the jam mode – in any position. › The workpiece carriers have very high anti-tipping safety; non-centred loading is not critical. › The junction unit kit includes all control elements, such as stoppers and sensors...

Open the catalog to page 11

MOTUS Workpiece carrier lift With a workpiece carrier lift, two transfer sections running parallel to each other on different planes can be easily connected to each other. An interesting solution when space is limited. Included: 1 Transfer section with electric drive 1 Set of sensors with holders for lifting cylinder 1 Vertical lift axle with pneumatic drive 1 Set of mounting material on the conveyor profile 1 Five-sided protective housing (the workpiece carrier inlet/outlet must be protected on the customer side) Without pneumatic valves. With the technical data/order data: Number of...

Open the catalog to page 12All ASYS GROUP catalogs and technical brochures

-

VEGO BCO 02

2 Pages

-

VEGO BCO 01

2 Pages

-

DIVISIO 6000

2 Pages

-

DIVISIO 2000/2100/2300

2 Pages

-

DIVISIO 1000

2 Pages

-

HYCON XH3D

2 Pages

-

PARIO 700 flex

2 Pages

-

LAMINO Cabin

2 Pages

-

DIVISIO 3100

2 Pages

-

DIVISIO 2000 Series

2 Pages

-

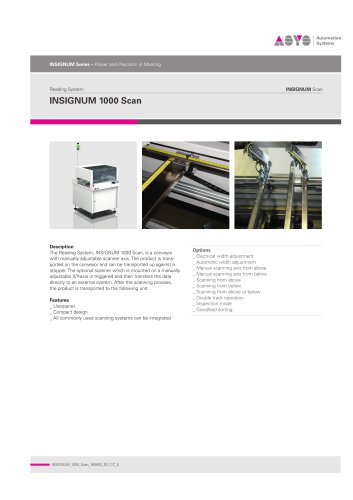

INSIGNUM 1000 Scan

2 Pages

-

INSIGNUM 3000 Scan

2 Pages

-

INSIGNUM 3000 Laser

2 Pages

-

DIVISIO 6000

2 Pages

-

S10 select

4 Pages

-

Metallization

4 Pages

-

Automatic Dispenser

4 Pages

-

Clamping Systems

8 Pages

-

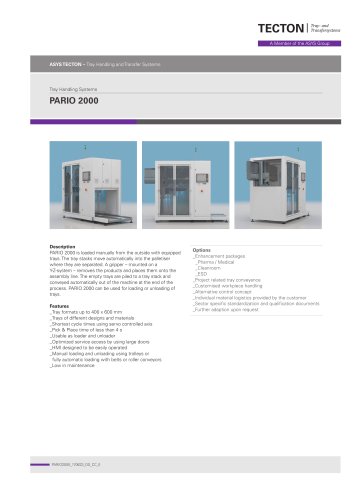

PARIO 2000

2 Pages

-

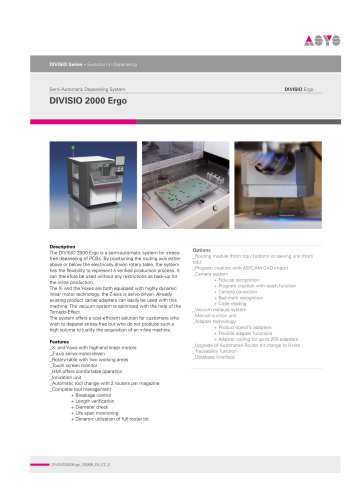

DIVISIO 2000 Ergo

2 Pages

-

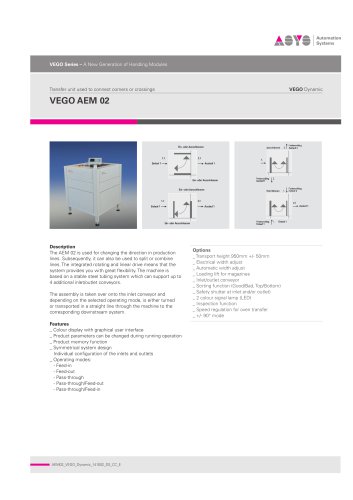

VEGO Dynamic AEM 02

2 Pages

-

VEGO Dynamic TDM 06

2 Pages

-

VEGO Dynamic AMS 06

2 Pages

-

VEGO Dynamic AMS 05

2 Pages

-

VEGO Dynamic AMS 04

2 Pages

-

VEGO Dynamic AMS 03 Speed

2 Pages

-

VEGO Dynamic LSB 03

2 Pages

-

VEGO Dynamic AES 03D

2 Pages

-

VEGO Dynamic AES 03 Speed

2 Pages

-

VEGO Dynamic AES 01

2 Pages

-

VEGO BLG 01

2 Pages

-

VEGO BTT 01

2 Pages

-

VEGO BFS 01

2 Pages

-

VEGO BBS 20

2 Pages

-

VEGO BUL 04

2 Pages

-

VEGO BUL 03

2 Pages

-

VEGO BUL 01

2 Pages

-

VEGO BST 01

2 Pages

-

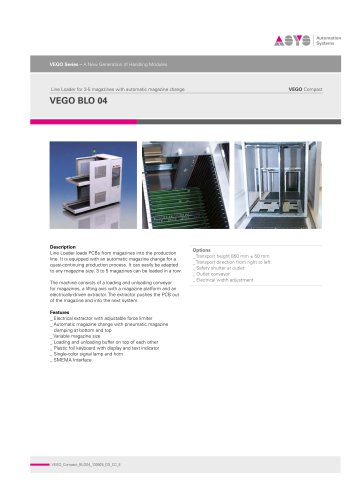

VEGO BLO 04

2 Pages

-

VEGO Dynamic STM 03D

2 Pages

-

VEGO Dynamic TRM 01-04

2 Pages

-

VEGO Hybrid HES 01

2 Pages

-

VEGO Hybrid HES 03

2 Pages

-

VEGO Hybrid HMS 01

2 Pages

-

VEGO Hybrid HMS 03

2 Pages

-

VEGO Compact BLO 03

2 Pages

-

VEGO Compact BLO 01

2 Pages

-

VEGO Compact BDS 01

2 Pages

-

INVENTUS series

4 Pages

-

INSIGNUM Laser

2 Pages

-

PARIO1000

2 Pages

-

DIVISIO2000 Ergo

2 Pages

-

DIVISIO4000

2 Pages

-

Compact_111108_DS

2 Pages

-

DIVISIO2000 Ergo Base

2 Pages

-

productbroschuere

2 Pages

-

EKRA_Product_Catalogue_20121

80 Pages

-

PM_CC_E

2 Pages

-

Ergo_Base_120906_

2 Pages

-

120419_D

2 Pages

-

VEGO Compact

2 Pages