Website:

ASYS GROUP

Website:

ASYS GROUP

Group: Asys

Catalog excerpts

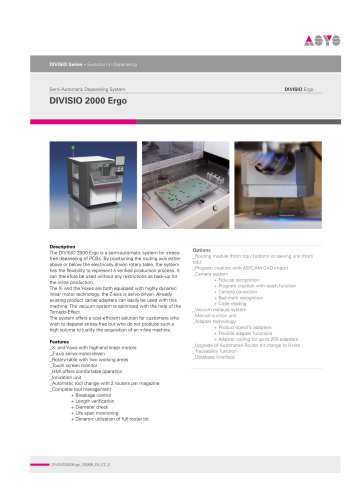

Automation Systems DIVISIO Depaneling Systems Semi-automatic Depaneling System DIVISIO 2000 Series Description The DIVISIO 2000 is a semi-automatic system for stress-free depaneling of PCBs. The X- and the Y-axes are both equipped with highly dynamic linear motor technology, the Z-axis is servo-driven. Already existing product carrier adapters can easily be used with this machine. The vacuum system is optimized with the help of the Tornado-Effect. The system offers a cost-efficient solution for customers who wish to depanel stress-free but who do not produce such a high volume to justify the acquisition of an inline machine. By positioning the routing axis either above or below the electrically driven rotary table the DIVISIO 2100 has the flexibility to represent a verified production process. It can therefore be used without any restrictions as back-up for the inline production. The DIVISIO 2300 commands the largest working area within the entire DIVISIO depaneling systems. Features _X- and Y-axis with high-end linear motors _Z-axis servo-motor-driven _Rotary-table with two working areas _Touch screen monitor _HMI offers comfortable operation Jonization unit _Automatic tool change with 2 routers per magazine _Complete tool management + Breakage control + Length verification + Diameter check + Life span monitoring + Dynamic utilization of full router bit _ Automatic maintenance schedule Options _Routing module (from top / bottom) or sawing unit (from top) _Program creation with ASYCAM CAD import _Camera system + Fiducial recognition + Cut control + Program creation with teach function + Camera correction + Bad mark recognition + Code reading _Vacuum exhaust system _Manual suction unit _Low pressure control _Adapter technology: + Product-specific adapters + Flexible adapter functions + Adapter coding for up to 255 adapters _Upgrade of Automated Router bit change to 8 bits _Traceability function _Database Interface

Open the catalog to page 1

Routing and/or Sawing Routing and/or Sawing Routing Machine Configuration Transport height Operating side Panel (max. LxB) Routing from top Routing from bottom Sawing from top in Y or X Sawing from top in X and Y NC-Axis 850 mm ± 50 mm Front of the machine 460 x 360 mm 460 x 360 mm 460 x 360 mm (Option) X/Y/Z- Axis Panel Dimensions Panel length Panel width Panel thickness Panel weight max. Component height, spindle-side Component height, adapter-side 50 bis 460 mm 50 bis 360 mm 0.5 bis 4.5 mm 4,5 kg 8 mm; partial 18 mm (other height on request) 40 mm; partial 70 mm (depending of fixing...

Open the catalog to page 2All ASYS GROUP catalogs and technical brochures

-

VEGO BCO 02

2 Pages

-

VEGO BCO 01

2 Pages

-

DIVISIO 6000

2 Pages

-

DIVISIO 2000/2100/2300

2 Pages

-

DIVISIO 1000

2 Pages

-

HYCON XH3D

2 Pages

-

PARIO 700 flex

2 Pages

-

LAMINO Cabin

2 Pages

-

DIVISIO 3100

2 Pages

-

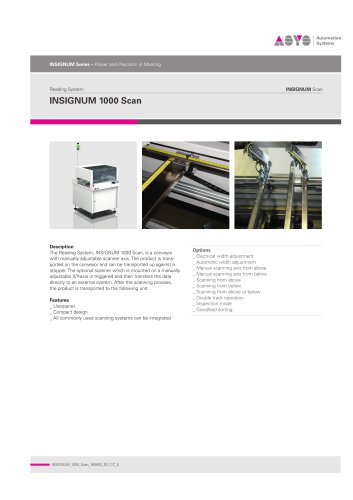

INSIGNUM 1000 Scan

2 Pages

-

INSIGNUM 3000 Scan

2 Pages

-

INSIGNUM 3000 Laser

2 Pages

-

DIVISIO 6000

2 Pages

-

S10 select

4 Pages

-

Metallization

4 Pages

-

Automatic Dispenser

4 Pages

-

Clamping Systems

8 Pages

-

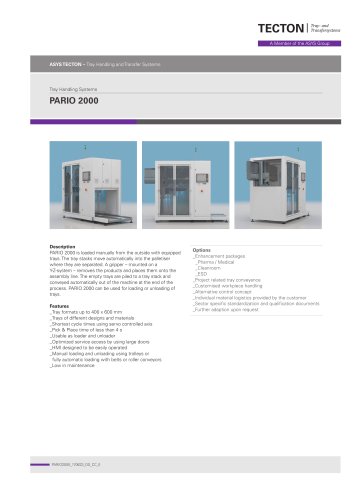

PARIO 2000

2 Pages

-

DIVISIO 2000 Ergo

2 Pages

-

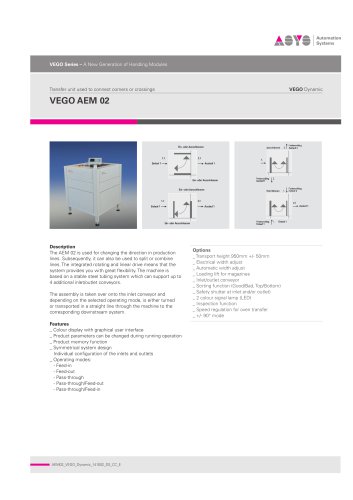

VEGO Dynamic AEM 02

2 Pages

-

VEGO Dynamic TDM 06

2 Pages

-

VEGO Dynamic AMS 06

2 Pages

-

VEGO Dynamic AMS 05

2 Pages

-

VEGO Dynamic AMS 04

2 Pages

-

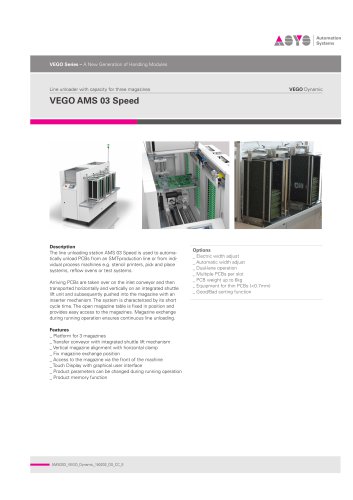

VEGO Dynamic AMS 03 Speed

2 Pages

-

VEGO Dynamic LSB 03

2 Pages

-

VEGO Dynamic AES 03D

2 Pages

-

VEGO Dynamic AES 03 Speed

2 Pages

-

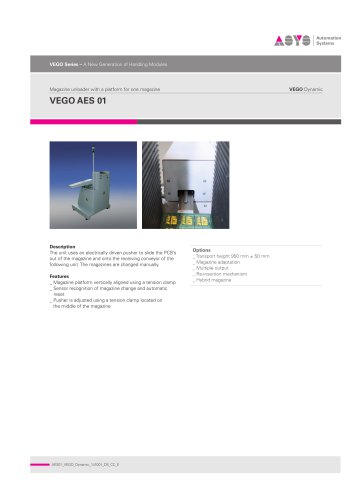

VEGO Dynamic AES 01

2 Pages

-

VEGO BLG 01

2 Pages

-

VEGO BTT 01

2 Pages

-

VEGO BFS 01

2 Pages

-

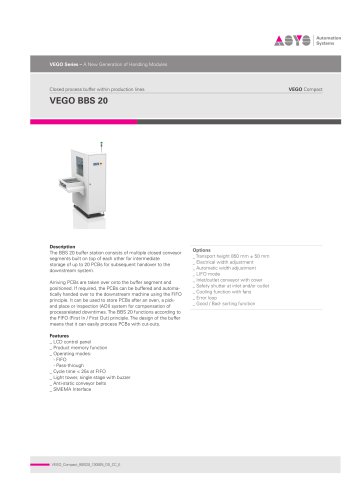

VEGO BBS 20

2 Pages

-

VEGO BUL 04

2 Pages

-

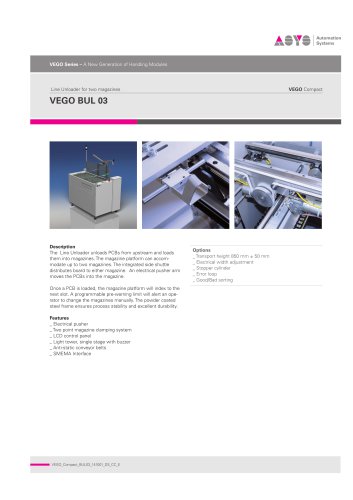

VEGO BUL 03

2 Pages

-

VEGO BUL 01

2 Pages

-

VEGO BST 01

2 Pages

-

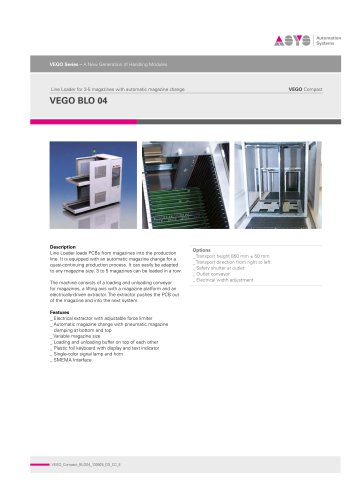

VEGO BLO 04

2 Pages

-

VEGO Dynamic STM 03D

2 Pages

-

VEGO Dynamic TRM 01-04

2 Pages

-

VEGO Hybrid HES 01

2 Pages

-

VEGO Hybrid HES 03

2 Pages

-

VEGO Hybrid HMS 01

2 Pages

-

VEGO Hybrid HMS 03

2 Pages

-

VEGO Compact BLO 03

2 Pages

-

VEGO Compact BLO 01

2 Pages

-

VEGO Compact BDS 01

2 Pages

-

MOTUS

21 Pages

-

INVENTUS series

4 Pages

-

INSIGNUM Laser

2 Pages

-

PARIO1000

2 Pages

-

DIVISIO2000 Ergo

2 Pages

-

DIVISIO4000

2 Pages

-

Compact_111108_DS

2 Pages

-

DIVISIO2000 Ergo Base

2 Pages

-

productbroschuere

2 Pages

-

EKRA_Product_Catalogue_20121

80 Pages

-

PM_CC_E

2 Pages

-

Ergo_Base_120906_

2 Pages

-

120419_D

2 Pages

-

VEGO Compact

2 Pages