Catalog excerpts

HINGED BELT TYPE CHIP CONVEYOR Hinged steel belt chip conveyors satisfy an exceptionally wide range of bulk conveying applications. They are suitable for managing heavy swarf and chip loads, stringy chips, continuous and discontinuous chips, high speed segmented chips and chip curls. Hinged steel belt chip conveyors are less suited for small aluminium chips. Hinged belt type chip conveyors are available in three different dimensions of the hinged belt link pitch: For lightweight industrial processing with the link pitch of t=40 For moderate weight industrial processing with the link pitch of t=63 For heavy industrial processing with the link pitch of t=100 We fabricate the conveyors in three forms: direct conveyor steep 1 angle conveyor steep 2 angle conveyor steep 1 angle conveyor steep 2 angle conveyor direct conveyor Choosing the right solution for conveying material, it is important to choose the form of the conveyor according to the schematic drawing showed in this Product Overview Map. The drawings show the key dimensions. The customer completes the Inquiry Form and enters the required dimensions L1, L2, L3.

Open the catalog to page 1

CDT HINGED STEEL BELT CONVEYOR CDT 40 Technical specification of industrial operating procedures: Carrying velocities for chip conveying of CDT 040, 063 and 100 range from 1 m/min up to 10 m/min Load carrying capacity: CDT40 up to 6 m3/hour (Approx. up to 3 tonnes/hour of assorted chips) Technical description: A - Width of the case B - Width of the loading section of the conveyor C - Width of the hinged link Dimensions L, L1, L2 and L3 conforming to customer's requirements We recommend the angle a to an extent of 60° in exceptional cases max. 70° The motor drive of the conveyor is situated...

Open the catalog to page 2

CDT HINGED STEEL BELT CONVEYOR CDT 63 Technical specification of industrial operating procedures: Carrying velocities for chip conveying of CDT 040, 063 and 100 range from 1 m/min up to 10 m/min Load carrying capacity: ■ CDT63 up to 12 m3/hour (Approx. up to 6 tonnes/hour of assorted chips) Technical description: ■ A - Width of the case ■ B - Width of the loading section of the conveyor ■ C - Width of the hinged link ■ Proportions of the hopper are optional ■ Dimensions L, L1, L2 and L3 conforming to customer's requirements ■ We recommend the angle to an extent of 60° in exceptional cases...

Open the catalog to page 3

CDT HINGED STEEL BELT CONVEYOR CDT 100 The conveyors with the pitch of the hinged belt link - 100 are designed for industrial heavy use and are therefore suitable for conveying of heavy swarf load. Primarily the repose angle of the discharge end of the conveyor is either 30°, 45° or 60°. Other repose angle has to be consulted with the conveyor manufacturer. Technical specification of industrial operating procedures: Carrying velocities for chip conveying of CDT 040, 063 and 100 range from 1 m/min up to 10 m/min Load carrying capacity: ■ CDT 100 up to 20 m3/hour (Approx. up to 10 tonnes/hour...

Open the catalog to page 4All ASTOS Machinery catalogs and technical brochures

-

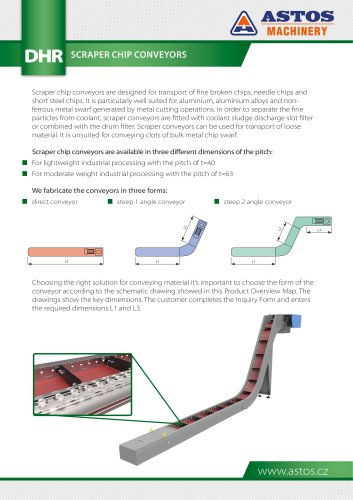

SCRAPER CHIP CONVEYORS

4 Pages

-

MAGNETIC CHIP CONVEYOR

4 Pages

-

CAROUSEL CHIP CONVEYOR

2 Pages

-

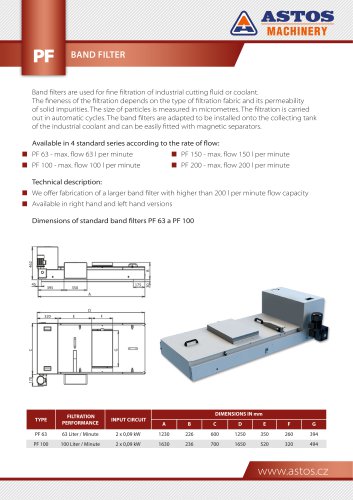

BAND FILTER

2 Pages

-

MAGNETIC SEPARATOR

1 Pages

-

FILTRATION STATIONS

2 Pages

-

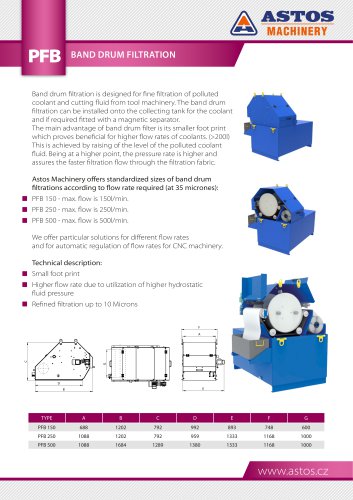

BAND DRUM FILTRATION

1 Pages

-

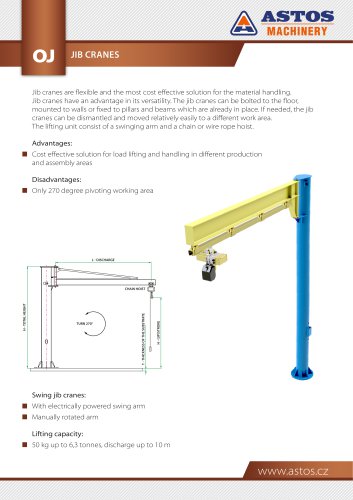

JIB CRANES

1 Pages

-

PF - Band filters

2 Pages