Catalog excerpts

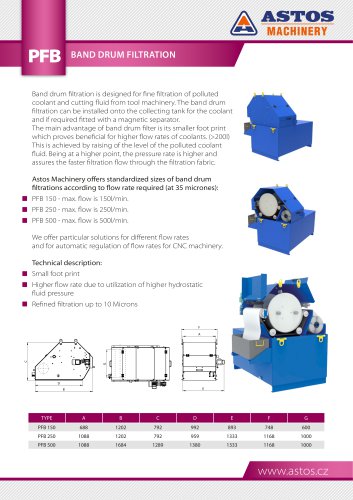

BAND DRUM FILTRATION Band drum filtration is designed for fine filtration of polluted coolant and cutting fluid from tool machinery. The band drum filtration can be installed onto the collecting tank for the coolant and if required fitted with a magnetic separator. The main advantage of band drum filter is its smaller foot print which proves beneficial for higher flow rates of coolants. (>2001) This is achieved by raising of the level of the polluted coolant fluid. Being at a higher point, the pressure rate is higher and assures the faster filtration flow through the filtration fabric. Astos Machinery offers standardized sizes of band drum filtrations according to flow rate required (at 35 micrones): ■ PFB 150 - max. flow is 150l/min. ■ PFB 250 - max. flow is 250l/min. ■ PFB 500 - max. flow is 500l/min. We offer particular solutions for different flow rates and for automatic regulation of flow rates for CNC machinery. Technical description: ■ Small foot print ■ Higher flow rate due to utilization of higher hydrostatic fluid pressure ■ Refined filtration up to 10 Microns TYPE A B C D E F G

Open the catalog to page 1All ASTOS Machinery catalogs and technical brochures

-

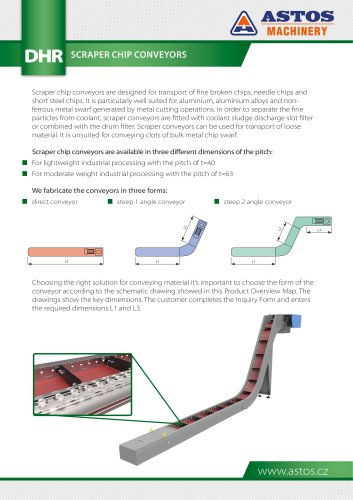

SCRAPER CHIP CONVEYORS

4 Pages

-

MAGNETIC CHIP CONVEYOR

4 Pages

-

CAROUSEL CHIP CONVEYOR

2 Pages

-

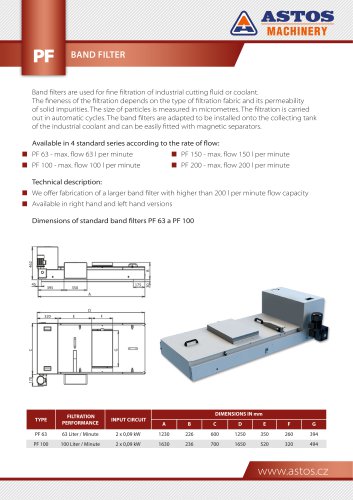

BAND FILTER

2 Pages

-

MAGNETIC SEPARATOR

1 Pages

-

FILTRATION STATIONS

2 Pages

-

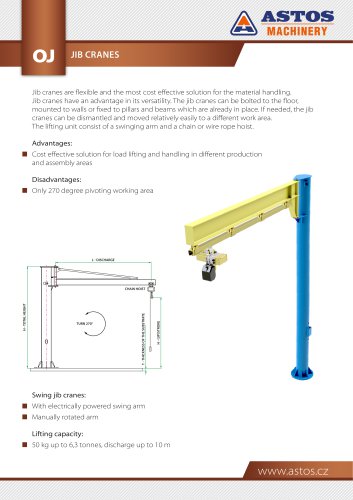

JIB CRANES

1 Pages

-

PF - Band filters

2 Pages

-

CDT – for CNC machines

4 Pages