Catalog excerpts

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic FEATURES B-Series switches have proven reliable in such harsh environments as: • Offshore oil rigs • Chemical and petrochemical plants • Pulp and paper mills • Steel mills • Power plants • Water and sewage-treatment plants • Other corrosive environments Ashcroft Inc. supplies highly reliable Ashcroft® switches and controls for industrial and process applications. We begin with rock-solid designs, matching the most appropriate technology with the safety and reliability requirements of the applications. The materials of construction are specified to Ashcroft’s exacting standards, and product is built to last in the toughest applications. Our modern, responsive manufacturing facility is supported by an extensive network of stocking distributors and factory sales offices located in virtually every part of the world. Special application assistance is always just a telephone call away. The Ashcroft B-Series switch line is designed to satisfy most switch requirements. Materials of construction have been selected for long life. A wide variety of precision switch elements are available to meet every application requirement, including hermetically sealed contacts for added reliability and safety. The actuators we use have been proven in more than 20 years of service in the world’s plants and mills. Special designs are available for fire safety, NACE, limit control and other more stringent requirements. Simplicity and ease of use are stressed to improve reliability of the installation. Applications include: pumps, compressors, washers, filters, degreasers, evaporators, recovery systems, food processing, ground support equipment, reverse osmosis systems, heat exchangers, hydraulic systems, lubrication systems, marine equipment, textile machinery, heating and air conditioning equipment. BULLETIN SW10 All specifications are subject to change without notice. All sales subject to standard terms and conditions. © Ashcroft Inc. 2007 10/08 Thermowells Thermowells must be used on any application where the stem of the temperature switch may be exposed to pressure, corrosive fluids or high velocity. Additionally, the use of a thermowell permits instrument interchange or calibration check without disturbing or closing down the process. Ashcroft temperature switches have bulb diameters to match 3⁄8˝ nominal bore thermowells. The bulbs have a sensitive portion length of 2˝ which can be used with 21⁄2˝ “U” dimensioned thermowells or longer. For maximum accuracy, a thermowell’s “U” dimension should be selected to permit complete immersion of the sensitive portion plus 1˝ when measuring the temperature of liquids; an extra 3˝ should be allowed when measuring the temperature of gases. Thermowell bushings should be used with remote mount temperature switches. We recommend the standard 3˝ bulb and code 69 Series bushings for use with any thermowell “U” dimension. A split rubber grommet allows easy installation and “S” dimension adjustment. Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281 • Fax: 203-385-0408 email: info@ashcroft.com • www.ashcroft.com

Open the catalog to page 1

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic Temperature Switches B-Series temperature switches feature a SAMA Class II vapor pressure thermal system. This system provides quick, accurate response to process temperature changes with negligible ambient temperature effects. This is inherent in the design due to the precise relation- ship that exists between temperature and pressure according to the vapor pressure laws. A wide selection of sensing bulb and armored capillary lengths is available. The vapor pressure system design features small bulb sizes, making...

Open the catalog to page 2

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic B-SERIES PRESSURE AND DIFFERENTIAL PRESSURE SWITCH MODEL NUMBER: To specify the exact switch desired, select entries from appropriate tables as shown in example below. 1 2 3 4 5 B 4 2 0 B X P K 600 PSI 1 – ENCLOSURE B4 B7 D4 D7 2 – SWITCH ELEMENT SELECTION Pressure switch, Type 400, watertight enclosure meets NEMA 3, 4, 4X, 13 and IP66 requirements. Pressure switch, Type 700, explosion-proof enclosure meets Div. 1 & 2, NEMA 7, 9 and IP66 requirements. Differential pressure switch, Type 400, watertight enclosure...

Open the catalog to page 4

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic B-SERIES TEMPERATURE SWITCH MODEL NUMBER: To specify the exact switch desired, select entries from appropriate tables as shown in example below. 1 2 T 4 3 2 0 4 T 0 5 030 X N H 150° to 260°F 1 – ENCLOSURE 3 – THERMAL SYSTEM SELECTION Direct Mount Temperature switch, Type 400, watertight enclosure meets NEMA 3, 4, 4X, 13 and IP66 requirements. Temperature switch, Type 700, explosion-proof enclosure meets Div. 1 & 2, NEMA 7, 9 and IP66 requirements. T4 T7 Order Code 23 24(1) 25 26(7) 27 28(5) 29(5) 31 32 42 50 61(7)...

Open the catalog to page 5

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic B-SERIES HYDRAULIC PRESSURE SWITCH MODEL NUMBER: To specify the exact switch desired, select entries from appropriate tables as shown in example below. 1 2 3 4 5 H 4 2 4 V X F S 3000 PSI 1 – ENCLOSURE Hydraulic pressure switch, Type 400, watertight enclosure meets NEMA 3, 4, 4X, 13 and IP66 requirements. H4 2 – SWITCH ELEMENT SELECTION Order Code 20(3) 21 22 23 24(1) 25 26(3) 27 28 29 32 42 61(3) 62(3) 63 64 65 70 Switch Elements UL/CSA Listed SPDT Narrow deadband ac 15A, 125/250 Vac Ammonia service 5A, 125/250 Vac...

Open the catalog to page 6

B-Series Switches – Pressure, Differential Pressure, Temperature & Hydraulic OPTIONAL FEATURES AND ACCESSORIES NOTES: B-SERIES SWITCH OPTIONS Code XBP XBX XCH XC8 XCN XFM XFP XFS XG3 XG5 XG6 XG7 XG8 XG9 XHS XHX XJK XJL XJM XK3 XLE XNH XNN XPK XPM XTA XTM XUD X06 X07 X6B Appicable Switch Series Differential TempPressure Pressure erature H All (psi) (in. H2O) (psi) (in. H2O) Ranges Description Wall Mounting Bracket in. H2O 1 ⁄2˝ Male NPT Bushing Chained Cover CSA Approval ATEX Directive 94/9/EC EEx d IIC T6 FM Approval – Single Element FM Approval – Dual Element Fungus Proofing Factory...

Open the catalog to page 7All ASHCROFT catalogs and technical brochures

-

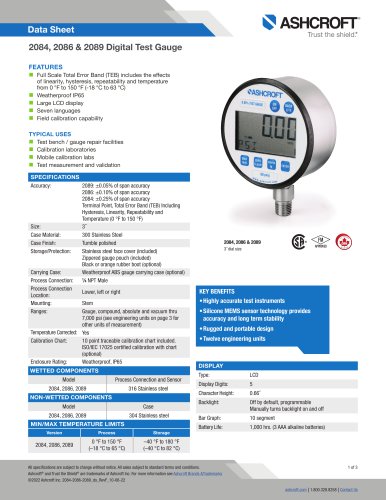

1259 Process Gauge

4 Pages

-

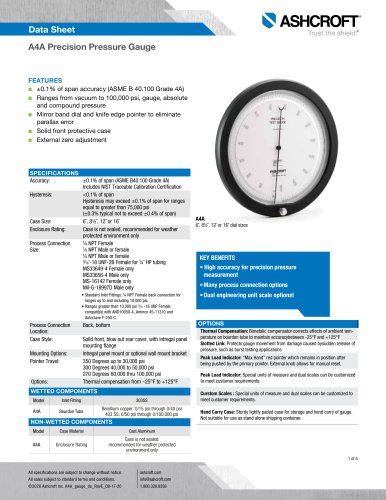

A4A Precision Pressure Gauge

5 Pages

-

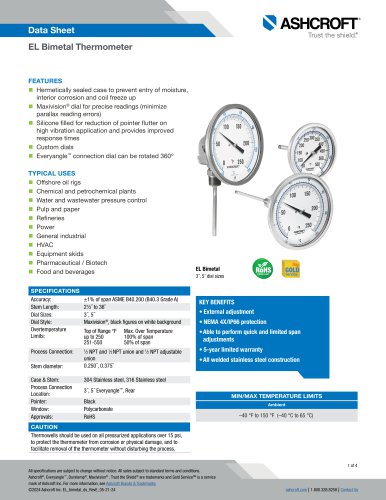

EL Bimetal Thermometer

4 Pages

-

A2 Pressure Transmitter

4 Pages

-

A4A Precision Pressure Gauge

4 Pages

-

1084 Test Gauge

2 Pages

-

1001T Panel Mount Gauge

4 Pages

-

1000 Commercial Gauge

2 Pages

-

Type 1339 Duplex Gauge

2 Pages

-

1038A Duplex Pressure Gauge

2 Pages

-

1220 Pressure Gauge

3 Pages

-

2008 Panel Pressure Gauge

4 Pages

-

1198 Finned Siphon

2 Pages

-

2198 MicroTube™ Siphon

3 Pages

-

1098 and 1100 Siphons

5 Pages

-

CI Bimetal Thermometer

2 Pages

-

EI Bimetal Thermometer

2 Pages

-

T6500 Pressure Gauge

5 Pages

-

T5500 Pressure Gauge

5 Pages

-

1109 Pressure Gauge

2 Pages

-

Acid Leak Detection (ALD)

4 Pages

-

5503

2 Pages

-

1209

3 Pages

-

1290

2 Pages

-

2462

2 Pages

-

Type 1133

2 Pages

-

Type 1127/1128

2 Pages

-

Model C-600A-03

2 Pages

-

Industry sanitary-pharm

4 Pages

-

302-303

4 Pages

-

T5500E

2 Pages

-

IXLDP

2 Pages

-

k1

2 Pages

-

K2

2 Pages

-

K8

2 Pages

-

km15

2 Pages

-

KS Sanitary

2 Pages

-

KX Transducers

2 Pages

-

RXLDP

2 Pages

-

SL17-TTS

1 Pages

-

SL 17 Submersible

2 Pages

-

T2 Transducers

2 Pages

-

600-01

2 Pages

-

600-02

2 Pages

-

600-03

2 Pages

-

600-04

2 Pages

-

600B

2 Pages

-

600H

2 Pages

-

ar10

4 Pages

-

ar20

4 Pages

-

at30 skin type thermocouple.

4 Pages

-

Type ST-2A Digital Indicator

2 Pages

-

Type 1305D Deadweight Tester

2 Pages

-

Model PT-1 Pressure Tester

2 Pages

-

ATE-2 Handheld Calibrator

12 Pages

-

SWGL

7 Pages

-

A N4

4 Pages

-

A series

8 Pages

-

600A

2 Pages

-

DT 600A

2 Pages

-

ash A4

2 Pages

-

A4

2 Pages

-

A2X

2 Pages

-

ASH DIG

3 Pages

-

DG 25

3 Pages

-

1008S

2 Pages

-

1008 A AL

2 Pages

-

1125

1 Pages

-

1009 1010

1 Pages

-

1010

2 Pages

-

Ash DG

2 Pages

Archived catalogs

-

Ash BM

2 Pages

-

Bimetal Thermometers - Series CI

8 Pages

-

Sanitary Gauges - Type 1032

4 Pages

-

Industrial Gauges Type 1017

24 Pages

-

Process Gauges Type 1279

16 Pages

-

Test Gauges Type 1082

12 Pages