Catalog excerpts

Type 1008A/AL Stainless Steel Metric Case Commercial Gauge PRODUCT SPECIFICATIONS: FEATURES • 63mm (2 1⁄2˝) and 100mm (4˝ case sizes • Corrosion-resistant stainless steel case/ring • Dry, field-fillable or liquid-filled versions • Patented PowerFlex™ movement • True Zero™ indication, a unique safety feature • Two-year warranty on liquid-filled gauges Ashcroft® Model No.: 1008A/AL Size: 63mm (21⁄2˝ ), 100mm (4˝ ) Case: 304 stainless steel, dry (1008A) or liquid filled (1008AL) Fill Fluid: Glycerin (20° to 150°F ambient; –7°C to 65°C) Ring: 304 stainless steel, crimped Window: Polycarbonate Dial: Black figures on white background, aluminum Pointer: Black, aluminum Bourdon Tube: – C-shaped Bronze (vac.-600 psi and compound) – Helical Bronze (1000 psi-6000 psi) – Helical stainless steel (10,000 psi15,000 psi) Movement: Patented PowerFlex TM movement Socket: Brass, with O-ring case seal Restrictor: Brass throttle plug, 0.013˝ orifice (except for vacuum 15 psi ranges) Connection: 1⁄4 NPT lower and back Ranges: Vac. thru 15,000 psi and compound. Equivalent metric ranges available Accuracy: ASME B40.100, Grade B, ±3-2-3% Operating Temp.: –40°F to 150°F, –40°C to 65°C (dry gauge) Ashcroft ® Type 1008A gauges are synonymous with durability, flexibility and exceptional quality. The Type 1008A case and ring assembly is constructed of durable, corrosion-resistant stainless steel. The gauge enclosure is sealed to provide maximum protection in adverse environmental conditions. The core of the Type 1008A is the patented PowerFlexTM movement. This movement provides a higher level of resistance to shock, vibration and pulsation than conventional gauge movements. Both 63mm and 100mm Type 1008A gauges are available dry, field fillable, glycerin filled or silicone filled. Weld nuts are standard on all back connection gauges, therefore, any back-connection gauge with the addition of a U-clamp accessory kit, can be panel mounted. For limited space constraints, the front-flange mounting kit is offered. Where it is necessary to convert a larger panel opening to a smaller size, the retrofit flange kit is available. Custom dials and metric sockets are also available. True Zero™ indication, a unique safety feature standard on these gauges, is the accurate indication of zero pressure being applied to the gauge. In addition to the increased safety benefits, this means reduced inspection and manufacturing costs for you and your customer. HOW TO ORDER OPTIONAL FEATURES: Case: Sealed case, field fillable (LJ) Silicone filled (GV) (–40°F to 150°F; –40°C to 65°C) Mounting Hardware: U-clamp (UC), Front flange (FF), Retrofit flange (RF) Socket: Throttle Plugs, 0.007, 0.020, 0.063˝ ˝ ˝ JIS, DIN and other connections on application Others: Customized dials, Nonstandard ranges, Special calibration on application FlutterGuardTM (eliminates rapid pointer flutter on most vibration/ pulsation applications – dry gauges only) COMMONLY USED ON Hydraulic systems, machine tools, pressure washers/sprayers, compressors, irrigation equipment, a variety of other applications (Typical example) 63 1008A L 02L 1000# Dial Size: 63mm Case Type Number: 1008A (SS case / bronze tube / brass socket / PowerFlex movement) Liquid Filled Case Connection Size/Location: 1⁄4 NPT Lower Range: 1000 psi BULLETIN CSS-1 All specifications are subject to change without notice. All sales subject to standard terms and conditions. © Ashcroft Inc. 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281 • Fax: 203-385-0408 email: info@ashcroft.com • www.ashcroft.com

Open the catalog to page 1

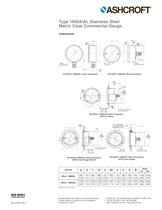

Type 1008A/AL Stainless Steel Metric Case Commercial Gauge DIMENSIONS H B B (3) (6) 0.25 (6) 0.25 (22) 0.88 C C C 0.13 A A 1 /4 NPT G 9 I (14) /16 ACROSS FLATS #8-32 THD 2 PLACES 9 I (14) /16 ACROSS FLATS (12) 0 .46 / NPT 14 63/100mm 1008A/AL Lower Connection 63/100mm 1008A/AL Back Connection (46) 1.81 1/4 (6) 0.25 NPT M PANEL CUTOUT ±1/32 C DD A H D (2) 1/16 TO (6) (35) 1.38 #8-32 LOCKWASHER NUT 3/8 (10) HEX 1/4 CUST. PANEL 63/100mm 1008A/AL Back Connection (XUC) U-Clamp 3X 5/32 (4) HOLES #6 FILISTER HEAD SCREWS & NUTS (6) 0.25 H B (6) 0.25 H 1/4 NPT M PANEL CUTOUT ±1/32 C DD C-1 E A D (2)...

Open the catalog to page 2All ASHCROFT catalogs and technical brochures

-

A4A Precision Pressure Gauge

4 Pages

-

1084 Test Gauge

2 Pages

-

1001T Panel Mount Gauge

4 Pages

-

1000 Commercial Gauge

2 Pages

-

Type 1339 Duplex Gauge

2 Pages

-

1038A Duplex Pressure Gauge

2 Pages

-

1220 Pressure Gauge

3 Pages

-

2008 Panel Pressure Gauge

4 Pages

-

1198 Finned Siphon

2 Pages

-

2198 MicroTube™ Siphon

3 Pages

-

1098 and 1100 Siphons

5 Pages

-

CI Bimetal Thermometer

2 Pages

-

EI Bimetal Thermometer

2 Pages

-

T6500 Pressure Gauge

5 Pages

-

T5500 Pressure Gauge

5 Pages

-

1109 Pressure Gauge

2 Pages

-

Acid Leak Detection (ALD)

4 Pages

-

5503

2 Pages

-

1209

3 Pages

-

1290

2 Pages

-

2462

2 Pages

-

Type 1133

2 Pages

-

Type 1127/1128

2 Pages

-

Model C-600A-03

2 Pages

-

Industry sanitary-pharm

4 Pages

-

302-303

4 Pages

-

T5500E

2 Pages

-

IXLDP

2 Pages

-

k1

2 Pages

-

K2

2 Pages

-

K8

2 Pages

-

km15

2 Pages

-

KS Sanitary

2 Pages

-

KX Transducers

2 Pages

-

RXLDP

2 Pages

-

SL17-TTS

1 Pages

-

SL 17 Submersible

2 Pages

-

T2 Transducers

2 Pages

-

600-01

2 Pages

-

600-02

2 Pages

-

600-03

2 Pages

-

600-04

2 Pages

-

600B

2 Pages

-

600H

2 Pages

-

ar10

4 Pages

-

ar20

4 Pages

-

at30 skin type thermocouple.

4 Pages

-

Type ST-2A Digital Indicator

2 Pages

-

Type 1305D Deadweight Tester

2 Pages

-

Model PT-1 Pressure Tester

2 Pages

-

ATE-2 Handheld Calibrator

12 Pages

-

SWGL

7 Pages

-

sw10

9 Pages

-

A N4

4 Pages

-

A series

8 Pages

-

600A

2 Pages

-

DT 600A

2 Pages

-

ash A4

2 Pages

-

A4

2 Pages

-

A2X

2 Pages

-

ASH DIG

3 Pages

-

DG 25

3 Pages

-

1008S

2 Pages

-

1125

1 Pages

-

1009 1010

1 Pages

-

1010

2 Pages

-

test gauges

3 Pages

-

1259

2 Pages

-

Ash SW10

9 Pages

-

Ash SWA

8 Pages

-

Ash DG 25

3 Pages

-

Ash DG

2 Pages

-

Ash Bul

3 Pages

-

Ash EL

2 Pages

-

Ash BM

2 Pages

-

Ash A2x

2 Pages

-

Ash A2 1 3

2 Pages

Archived catalogs

-

Bimetal Thermometers - Series CI

8 Pages

-

Sanitary Gauges - Type 1032

4 Pages

-

Industrial Gauges Type 1017

24 Pages

-

Process Gauges Type 1279

16 Pages

-

Test Gauges Type 1082

12 Pages