Catalog excerpts

Assembly • Industrial • Precision Fastening The new range of Delta air screwdriver has been specially designed and manufactured by Fiam to solve fastening problems when using self-threading, self-tapping, self-shaping and self-drilling screw situations where the final tightening torque is lower than the driving, threading or tapping torque. f torque during the fastening process with self-threading screws, etc. A Bushing customized according to the dimensions and types of screw being used. Its special form makes visual control easy for the operator during assembly operations. Manufactured in a special resistant plastic material, it is wear-proof and does not damage the surface of the piece to be tightened. Magnetized bit, customized according to the shape of screw head: the screw can be positioned easily and safely (while the screwdriver is turned off). Adjusting nut used to position the bushing correctly in relation to the underhead of the screw. Step 1: Enlarging and tapping hole. During this phase, the screwdriver produces the maximum torque necessary for threading or tapping. Step 2: The tool produces the torque necessary to bring the screw into contact with the surface of the work piece. Step 3: When the underhead of the screw comes into contact with the surface of the work piece: the Delta clutch is engaged to stop the screwdriver automatically at the preset torque value ASG is Proud to be Fiam's Exclusive Master Distributor for North America

Open the catalog to page 1

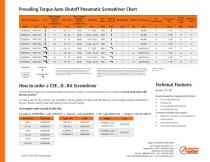

Lever Start \ Push Button Start The value indicated is the maximum generated by all the tool in order to overcome the enlarging and threading/tapping phase. The torque required in this phase depends on the screw used and the type if joint; therefore the screwdriver may give lower torque values than the maximum shown in the table The figures shown are measured at a pressure of 91.4 PSI, 6.3 bar (ISO 2787), the recommended operating pressure. The tightening torque values have been measured in accordance with ISO 5393 standard. Sound pressure level has been measured in accordance with ISO 3744...

Open the catalog to page 2All ASG Division of Jergens catalogs and technical brochures

-

Manual Torque Products

24 Pages

-

Torque Reaction Assemblies

1 Pages

-

Fiam IH Series Pulse Tools

2 Pages

-

Push-To-Start Adapter Kits

1 Pages

-

HIOS Product Line

16 Pages

-

Weld Stud Test Tool

1 Pages

-

ASG Automation Systems Catalog

12 Pages

-

ASG Premium Torque Arms Catalog

28 Pages

-

Assembly products

102 Pages

-

ASG Premium Auto Feed Catalog

12 Pages

-

H Series Tube Nut Wrenches

2 Pages

-

EZ-10k Auto Tape Dispenser

2 Pages

-

X-Guard™ For Sd2500 X-Paq™

1 Pages

-

Who We Are

1 Pages

-

Screw Presenter

1 Pages

-

EZ 9000 GR

2 Pages

-

ASG Electric Screwdriver Catalog

25 Pages

-

ASG Manual Torque Catalog

24 Pages