Catalog excerpts

Swiss type machining With ARNO you benefit from reliable processes, long tool life, a revolutionary tool changing system and more productivity in your Swiss type machining production shop.

Open the catalog to page 1

ARNO FOR OUTSTANDING PRODUCTIVITY OUTSTANDING FOR MORE PRODUCTIVITY IN YOUR PRODUCTION. Do you have challenging machining tasks? We have outstanding solutions. For three generations, we have been developing tool systems which have outstanding quality, long tool life and process reliability. As an ARNO customer you benefit from a combination of experience and pioneering spirit. Besides these values we are also influenced by the typical Swabian talent for inventiveness. We are proud to assist our customers to secure that extra competitive advantage with clever new developments and...

Open the catalog to page 2

SWISS TYPE MACHINING WITH ARNO. 04 10 The ARNO added value Swiss type machining highlights 22 ARNO systems for Swiss type machining 24 Overview 26 and SE grooving systems | Parting off and grooving, copy turning SA 28 AMS – ARNO Mini-System | Internal machining 30 ISO turning | External and internal machining 32 DECO-CUT | Groove turning system 34 SHARK-CUT | Multi purpose tool 36 Overview of applications 38 42 Success story ARNO Services

Open the catalog to page 3

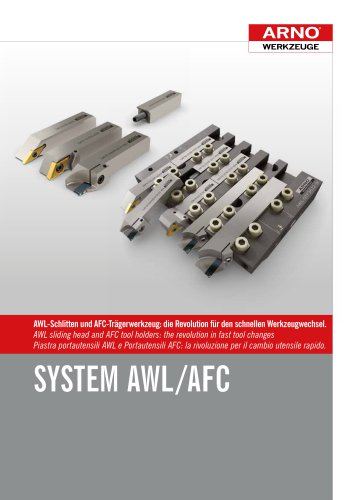

THE ARNO ADDED VALUE – OVERVIEW OF BENEFITS MASSIVE BENEFITS. Fast tool changes Fast, simple, safe, precise: ARNO Fast Change, in short AFC, with two-part tool holder – for speed and convenience when changing tools. Cool sliding head An end to jumbled hoses – thanks to the AWL sliding head with integrated coolant supply for perfect set-ups. Patented cooling system ACS – ARNO Cooling System: the original from ARNO Werkzeuge – coolant is supplied through the insert seat and goes under the swarf. 300% longer tool life Even with deep, narrow part-off and grooving operations, the ACS – ARNO...

Open the catalog to page 4

Extremely high-positive Precise fit for any application: The largest portfolio of high-positive indexable inserts in the world is the solution or thin-walled parts and materials that are difficult to machine. Multi purpose Turning and drilling with only 1 tool: SHARK-CUT is the solution for the lack of tool positions on the machine. 70 to 90% potential savings Tests at customer sites show that the high-performance SA and SE grooving systems from ARNO achieve very high cost savings. Perfectly centred The ARNO Mini-System permits perfect positioning at tip height straight away. Loads of PS...

Open the catalog to page 5

THE ARNO ADDED VALUE – INTERVIEW IF YOU HAVE A SWISS TYPE MACHINE, YOU SHOULD GET TO KNOW ARNO. Interview with: Klaus-Dieter Krüger, Sales Manager North at ARNO Werkzeuge on clever ARNO solutions for Swiss type machining. Why should customers opt for ARNO when they require Swiss type machining applications? I can think of many reasons why. For example, Swiss type machines are almost always used in mass production. That’s where our SA and SE grooving systems achieve extremely long tool life. Most applications deal with the production of filigree shapes – and our inserts with the PS-geometry...

Open the catalog to page 6

“Companies who use AFC never want to give it up!” What’s so special about AFC holders? The two-part holders make tool changing a sure thing – anybody can do it. Only the front part needs to be removed to replace the insert. When the two holder parts are plugged back together, they are immediately connected by an O-ring to prevent the tool from falling into the machine accidentally. The floating mount makes the parts fit together perfectly. It compensates for the offset angle so we achieve a high level of repeatability. Customers who already use AFC holders really appreciate them. They...

Open the catalog to page 7

THE ARNO ADDED VALUE – POTENTIAL SAVINGS THE TURBO COMBINATION FOR SWISS TYPE MACHINES. The challenge Swiss type machines pose special problems to users due to their limited space. In many cases, installing and adjusting coolant supply and replacing inserts is a difficult and time-consuming operation. This causes unnecessarily long machine downtimes and, in the worst case, even production errors. The solution A combination of AFC tool holders and AWL sliding heads: · FC for fast and easy tool changes – thanks to the two-part tool holder where only A the front part needs to be removed to...

Open the catalog to page 8

minutes saved per tool change minutes per week per machine savings with AFC holders per year / per machine Piping the machine per set-up operation 2 set-up operations per week Savings = €2,700 + €4,050 = €6,750 per year / per machine savings from AWL sliding heads per year / per machine €168,750 total savings per year wit

Open the catalog to page 9

ARNO SYSTEM HIGHLIGHTS SWISS TYPE MACHINING – OVERVIEW INNOVATIVE HIGHLIGHTS FOR MORE PRODUCTIVITY. When the application involves the mass production of long narrow parts made of bar material, Swiss type machines are unbeatable. They work even better with precise, long-lasting tools, effective cooling and easy tool changing. That’s exactly what we offer: AFC tool holders PACEMAKER Perfect for simple, reliable and fast tool changes: the two-part AFC holder makes tool changes so easy and lightning fast. See page 12 for more details on AFC holders. SIMPLY COOL Efficient coolant supply is so...

Open the catalog to page 10

“With AFC and AWL we make things easier for the customer.” Swiss type machines are great and also easy to operate – the only thing is that tool changes are complicated. There is simply too little space. That is why machine operators need more time and easily make mistakes. That was the reason for developing the AFC. The two-part shank system and the floating mount make tool changes much simpler, faster and above all more precise than before. Besides this, we also took a good look at cooling. AWL sliding heads do not have anymore jumble of hoses. Everything is leak-proof and coolant supply...

Open the catalog to page 11

ARNO SYSTEM HIGHLIGHTS SWISS TYPE MACHINING – AFC – ARNO FAST CHANGE SWISS TYPE MACHINING, FAST CHANGES. AFC tool holders: the revolution in fast tool changes – patent applied. Your solution for easy tool changes despite limited space in Swiss type machines: the two-part AFC holder – even untrained staff can replace tools fast and reliably. This is how it works: The rear part of the tool holder (AHA fixed stop) is first fixed in place. Only the front part is removed to replace the tool. This eliminates the need to restart and recalibrate the zero point since the length to the insert tip is...

Open the catalog to page 12All Arno Werkzeuge catalogs and technical brochures

-

COMPETENCE turning

52 Pages

-

COMPETENCE parting and grooving

44 Pages

-

SYSTEM ATS

36 Pages

-

SYSTEM AFC & AWL

108 Pages

-

SYSTEM SHARK-DRILL²

40 Pages

-

SYSTEM Tool-Tip AS1005

4 Pages

-

SYSTEM Tool-Tip AM7010-7020

12 Pages

-

SYSTEM Tool-Tip AP3815/AP3925

24 Pages

-

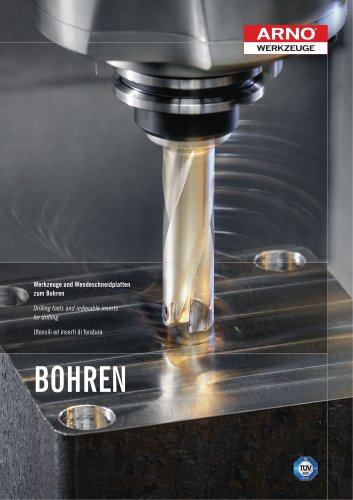

Catalogue drilling

284 Pages

-

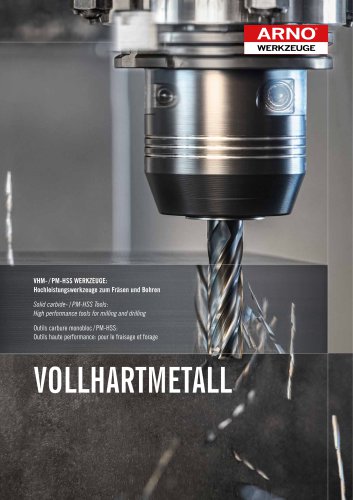

Catalogue milling

324 Pages

-

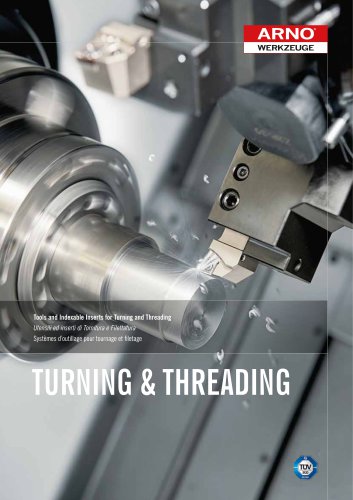

Catalogue turning & threading

804 Pages

-

Catalogue auto lathes

692 Pages

-

Catalogue parting and grooving

788 Pages