Website:

Arno Werkzeuge

Website:

Arno Werkzeuge

Catalog excerpts

Parting off and grooving When you work with ARNO tools, you benefit from reliable processes when it comes to complex grooving operations, and long tool life and higher productivity in your production.

Open the catalog to page 1

ARNO FOR OUTSTANDING PRODUCTIVITY OUTSTANDING FOR MORE PRODUCTIVITY IN YOUR PRODUCTION. Do you have challenging machining tasks? We have outstanding solutions. For three generations, we have been developing tool systems which have outstanding quality, long tool life and process reliability. As an ARNO customer you benefit from a combination of experience and pioneering spirit. Besides these values we are also influenced by the typical Swabian talent for inventiveness. We are proud to assist our customers to secure that extra competitive advantage with clever new developments and...

Open the catalog to page 2

PARTING OFF AND GROOVING WITH ARNO. 04 10 The ARNO added value Grooving: system highlights 18 ARNO grooving systems 20 Overview 22 grooving system and SE groove turning system | SA Parting off, grooving and copy turning 24 NC universal grooving system | Radial, axial and ”Kontra” grooving 26 AMS – ARNO Mini-System | Internal machining 28 SIM | Internal machining 30 SHORT-CUT| Grooving and turning system 32 CLIP-GROOVE | Circlip grooving system 34 PROFIL-CUT | Form grooving system 36 Range of applications 38 42 Success story ARNO Serv

Open the catalog to page 3

THE ARNO ADDED VALUE – OVERVIEW OF BENEFITS IRRESISTIBLE ARGUMENTS. World premiere: 3D grooving module The first 3D printed grooving module manufactured in series. It has two cooling holes, one of them triangular, to ensure optimum cooling and chip removal even in complex grooving operations. Patented cooling system ACS – ARNO Cooling System: the original from ARNO Werkzeuge – the coolant hole is going through the insert seat and brings the coolant underneath the swarf. Tool life longer by 300% Even with narrow, deep parting off and grooving operations the ACS – ARNO Cooling System achieves...

Open the catalog to page 4

Perfectly centred The ARNO AMS Mini-System always achieves immediate perfect positioning at tip height. Stable processes Short and correct: maximum stability for parting off and grooving with ARNO flange mounted holders for many machine manufacturers and types. 70 – 90% potential savings Tests at customers show that the high-performance SA and SE grooving systems from ARNO save enormous costs. Wide range of applications All-inclusive package We help make your work easier all the way down the line by providing personal consultation, fast delivery and extensive documentation. No matter what...

Open the catalog to page 5

THE ARNO ADDED VALUE – INTERVIEW WE ARE GENUINE GROOVING SPECIALISTS! Interview with: Dieter Wollensack, Sales Manager South at ARNO Werkzeuge. Why should a customer opt for ARNO when it comes to parting off and grooving solutions? Because we can cover an enormous range of applications. Many customers do not know that we are genuine grooving specialists. Our tools up to a diameter of 65 mm perform at least as good as our competitors‘ tools and often even much better than our competitors. This is not just what we claim, it has been proven in daily prac tice by our customers. A 300 per cent...

Open the catalog to page 6

“A 300 per cent longer tool life is almost always achievable.” What are the trends in the parting off and grooving sector? The future will focus more and more on saving material by applying narrow grooving and parting off. And efficient cooling is the key to stable processes. With ACS2 we are in a great position here. But of course we’re not going to leave it at that. In collaboration with Rosswag Engineering, we have now launched the world’s first 3D-printed modules produced in series. They’re very narrow but still have two coolant holes. The one underneath the tool flank is even...

Open the catalog to page 7

THE ARNO ADDED VALUE – POTENTIAL SAVINGS 1 MILLIMETRE LESS – SAVINGS OF 429,000 EURO. The challenge: educe groove widths, guarantee process reliability. r Every industrial company knows this problem: production costs rise faster than they can raise the prices of the products sold. This uneven development must be countered by introducing efficient processes and reducing costs. For example, a lot of material can be saved in grooving operations by reducing groove width – provided process reliability and tool life remain the same. To achieve this, the tool system, espe cially the overhang...

Open the catalog to page 8

The result: enormous savings with identical tool life. A combination of ARNO flange mounted holder, grooving module and ACS2 can reduce the groove width from 3 mm to 2 mm without reducing tool life. Grooving work continues smoothly. Another benefit is the fact that ACS gets the coolant underneath the swarf and guarantees optimum cutting conditions – wrong positioning of the coolant is not possible. Material saved per year assuming 220 machine-days metres material savings year / machine Material savings metres of material saved year / machine metres Total savings per year Cost savings per...

Open the catalog to page 9

ARNO SYSTEM HIGHLIGHTS: GROOVING – OVERVIEW INNOVATIVE HIGHLIGHTS FOR MORE PRODUCTIVITY. When it comes to grooving applications, ARNO is one of the best. And we’re right up among the leaders there – that’s because no other tool manufacturer can offer you these highlights: ACS – ARNO Cooling System 3 TIMES LONGER TOOL LIFE The cooling system patented by ARNO: Only ACS gets the coolant underneath the swarf and guarantees optimum cutting conditions. For opti ised insert cooling and reliable chip m removal. ACS2 also has a second coolant hole which cools the tool flank from underneath. That’s...

Open the catalog to page 10

“The question is what does the customer need?” As head of development at ARNO, it’s my gob to look very closely at what is used on the market and, if necessary, make good products even better. This is because there is an increasing demand for speed, quality and flexibility. It explains why we continue to further develop what is already a very good SA grooving system – it’s outstandingly reliable, fast and durable and when combined with the ACS Cooling System it’s easy to use in the application. This provides our customers a very clear competitive advantage – and for us it confirms that it’s...

Open the catalog to page 11All Arno Werkzeuge catalogs and technical brochures

-

COMPETENCE turning

52 Pages

-

COMPETENCE swiss type machining

44 Pages

-

SYSTEM ATS

36 Pages

-

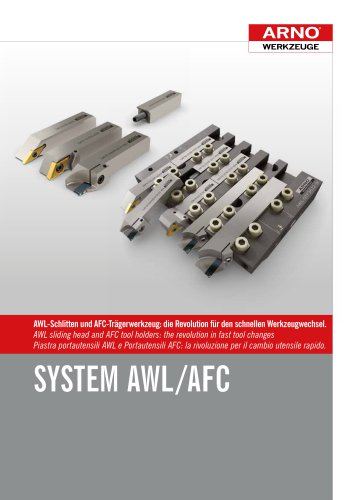

SYSTEM AFC & AWL

108 Pages

-

SYSTEM SHARK-DRILL²

40 Pages

-

SYSTEM Tool-Tip AS1005

4 Pages

-

SYSTEM Tool-Tip AM7010-7020

12 Pages

-

SYSTEM Tool-Tip AP3815/AP3925

24 Pages

-

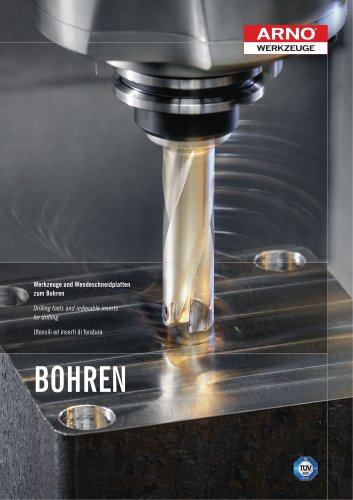

Catalogue drilling

284 Pages

-

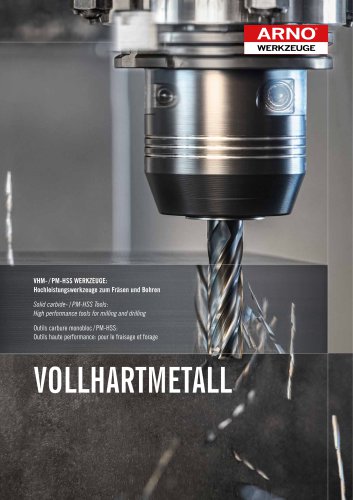

Catalogue milling

324 Pages

-

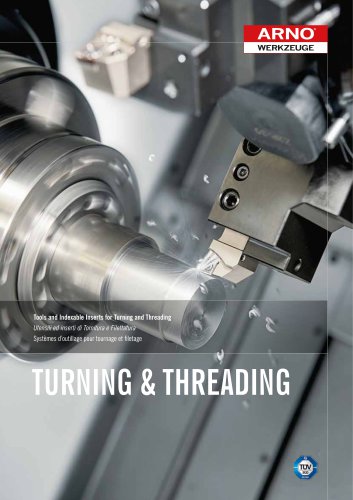

Catalogue turning & threading

804 Pages

-

Catalogue auto lathes

692 Pages

-

Catalogue parting and grooving

788 Pages