Website:

Armo s.p.a.

Website:

Armo s.p.a.

Catalog excerpts

PAW-L dock shelter DT-3903 TECHNICAL DESCRIPTION AND ASSEMBLING MANUAL DOCK SHELTER

Open the catalog to page 1

• TECHNICAL DESCRIPTION • ASSEMBLING INTRODUCTION • DIMENSIONS • INSTALLATION SEQUENCE • INSTALLATION PICTURES • MAINTENANCE - DISPOSAL

Open the catalog to page 2

TECHNICAL DESCRIPTION utamale The dock shelter is necessary to correctly isolate your staff and goods of your warehouses from bad weather conditions and sudden variations of temperature. With a dock shelter installation you will obtain a considerable energy saving. • Dock shelter with frontal sheet in black rubber and different degree of stiffness. • Opening/closing device through swinging arms. The truck, reversing, pushes the dock shelter structure without causing any damages. • Self-supporting structure in SENDMIR galvanized steel tube, telescopic type, to reduce possible impacts with...

Open the catalog to page 3

TECHNICAL DESCRIPTION utamale TECHNICAL DETAILS

Open the catalog to page 4

ASSEMBLING INTRODUCTION This instruction manual allows the authorized staff to use the dock shelter properly and to carry out the necessary maintenance works, avoiding, possibly, even mortal dangers, which come from a wrong use of the product. We remind that installation, maintenance, fixing up and checks must be execute by specialists. The safety rules define like “expert” a person who, according to his technical training and experience, knows enough the dock shelters sector and has familiarity with their regulations in order to establish their safety conditions. All data, which appear in...

Open the catalog to page 5

ASSEMBLING INTRODUCTION utamale WORKING EQUIPMENT • Handle tools • Electric drill • crowbar • spirit level or other tools • continuous wire electric welder • grinder DPI • safety shoes • safety helmet • ear protectors • Gloves MAIN RULES OF REFERENCE Legislative decree n.277 dtd. 15/08/1991 Legislative decree n.81/2008 (only text on safety) Legislative decree n.106/2009 (updating at the only text on safety) RISK • Falling from top and at level • Abrasions, pricks, cuts, lacerations to the hands • Shock, hits, impacts, compressions to the hands • Electrocution • Falling od materials from...

Open the catalog to page 6

ASSEMBLING INTRODUCTION PAW-L dock shelter is made by the following elements: A. B. C. D. E. F. G. A walled structure, composed by three elements; Four brackets, 2 per side A frontal archway, composed by three elements in aluminium, which support the rubber sheets Outside aluminium perimeter. Upper sheet in anti-wear rubber. Two lateral rubber sheets. Installation Kit

Open the catalog to page 7

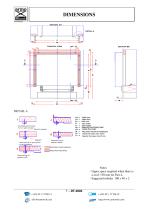

Notes - Upper space required when there is a roof: 150 mm for Paw-L - Suggested tubular 100 x 40 x 2

Open the catalog to page 8

INSTALLATION SEQUENCE WARNING: once opened the packaging, check that the product has not been damaged during the transport. If you remark any faults, it is imperative to report them immediately to the forwarder on the delivery note, as well as inform the producer and the retailer. Before starting the installation, check the dimensions of the hole: width and height. For the standard assembling, these measures must correspond to at least 120 mm lower than the outside dimensions of the portal. Also check the flatness of the surface on which the dock shelter will be mounted and the correct...

Open the catalog to page 9

INSTALLATION SEQUENCE GROUND ASSEMBLING

Open the catalog to page 10

INSTALLATION SEQUENCE GROUND ASSEMBLING

Open the catalog to page 11

INSTALLATION SEQUENCE GROUND ASSEMBLING

Open the catalog to page 12

INSTALLATION SEQUENCE GROUND ASSEMBLING

Open the catalog to page 13

INSTALLATION SEQUENCE PICTURES Hereinafter we list the assembling phases of the dock shelter, explained thanks to related pictures: 1) Proceed by assembling the rear frame with intermediate brackets

Open the catalog to page 14

INSTALLATION SEQUENCE PICTURES 2) Assembling of the frontal and lateral rubber sheets by making them sliding into the suitable sections in the aluminium frontal structure

Open the catalog to page 15

INSTALLATION SEQUENCE PICTURES 3) Assembling of the upper frontal rubber sheet, by making it sliding into the suitable section in the aluminium frontal structure. Combine then the frontal and the rear structures together.

Open the catalog to page 16

INSTALLATION SEQUENCE PICTURES 4) Connection between the lateral and upper aluminium frames; then fix the frontal frame to the rear one by employing the brackets.

Open the catalog to page 17

INSTALLATION SEQUENCE PICTURES 5) Insert the lateral and upper protections, using the “thickness” ( not included in the supplying) in order to keep slightly opened the structure pantograph

Open the catalog to page 18

INSTALLATION SEQUENCE PICTURES 6) Raising of the portal from the upper part and install it against the wall;

Open the catalog to page 19

INSTALLATION SEQUENCE PICTURES 7) Flexible stretch mounting

Open the catalog to page 20

INSTALLATION SEQUENCE PICTURES 8) Final result once the shelter is fixed to the wall. 9) Sealing of the whole perimeter with silicone where the rear profile of the shelter and the wall come into contact, in order to prevent possible infiltration of rainwater.

Open the catalog to page 21

MAINTENANCE - DISPOSAL MAINTENANCE - Clean the PVC with neutral substances (for instance shampoo for cars) and rinse out. - To fix possible wears with pvc patches and by employing an industrial blow dryer or a suitable glue. - After disassembling the portal, it is required to share the single parts (padding, wood panel, pvc coating, steel frame), and proceed by a standard disposal of the metallic parts. POISONOUS SUBSTANCES DISPOSAL The poisonous substances, which compose the portal are: - The PVC sheet - Expanded polyurethane padding These substances are disposable by the suitable...

Open the catalog to page 22All Armo s.p.a. catalogs and technical brochures

-

Dock Scissor Tables

14 Pages

-

Dock Levellers

18 Pages

-

Dock levellers - Methods for pit

12 Pages

-

Loading bays - Armo Docks

4 Pages