Website:

ARKU Maschinenbau GmbH

Website:

ARKU Maschinenbau GmbH

Catalog excerpts

Deburring with ARKU. Double-sided, rapid, reliable.

Open the catalog to page 1

»Every development reflects the passion for our work.« Ewald Hund, Head of Development, ARKU Sheet metal fabrication is becoming increasingly demanding and companies are focusing more and more on automated deburring. Our customers need to position themselves amongst the com petition via high quality parts and low unit costs. We dedicate our entire passion to developing solutions for better sheet metal quality. The EdgeBreaker® series from ARKU: for optimal processing within your production

Open the catalog to page 2

Deburring, rounding, oxide removal Punched and laser-cut parts starting at 0.5 mm (0.02" ) thick Find our entire machine portfolio at arku.com / products-usa Toll processing, consulting, service. The ARKU Leveling and Deburring Centers. (( Contract leveling and contract deburring Many materials, one result: quality. Remove heavy burrs and slag produced by flame (oxyfuel) or plasma cutting heavy plates. Or reliably remove burrs from thin sheets / parts after punching and laser cutting. No matter how diverse your requirements and part quantities are: Deburring and rounding with ARKU increases...

Open the catalog to page 3

Double-sided deburring and rounding. In a single pass. Efficient double-sided automated deburring and rounding: The EdgeBreaker® has opened up new dimensions in working with punched, laser-cut and flame-cut parts. The results ensure highly reliable processes even with large quantities combined with significant time, tool and personnel savings. Intuitive: Control via the touchscreen HMI. Unique performance: The grinding drum is capable of reliably removing even large burrs. Patented: The consumables can be replaced in a matter of moments using the clicksystem. For example when changing from...

Open the catalog to page 4

Producing more while protecting your staff. Productivity that can be measured: automa ted deburring and edge-rounding with the EdgeBreaker®. This improves our customers’ competitiveness, enhances their flexibility and frees up time for additional orders. »With ARKU, we can guarantee consistently high part quality even with large quantities. This strengthens our position amongst the competition.« Norman Straub (left), Business Administration Director of Sheet Metal Processing, and Simon Straub, Production Manager, Eisen- und Stahlhandel Straub GmbH, Germany in 5 hours with manual deburring...

Open the catalog to page 5

FlatJack® for automatic flatness control A robot for automatic parts feeding EdgeBreaker® for efficient deburring and rounding Automate processes and flexibly chain them together. FlatMaster® for precise parts leveling A culture of innovation with a tradition: ARKU repeatedly ranks among the top 15 most innovative mid-size German companies in studies carried out by the German magazine WirtschaftsWoche. Efficiently chaining processes together. Especially when it comes to machines which are becoming increasingly independent in perfectly coordinated and automated production lines. Already a...

Open the catalog to page 6

ARKU Inc. 11405 Grooms Road, Cincinnati OH 45242, United States Phone: +1 [513] 985-0500 deburring@arku.com www.arku.com

Open the catalog to page 7Archived catalogs

-

Coil Lines

12 Pages

-

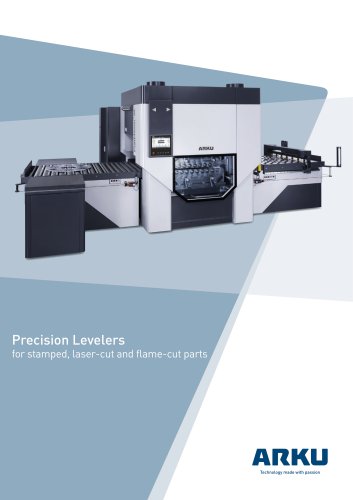

Leveling machines by ARKU

12 Pages