Website:

ARI-Armaturen

Website:

ARI-Armaturen

Catalog excerpts

Press release for ACHEMA 2006 Save energy with the new, patent-pending test device for all ARI steam traps! “CONA® system”: ...thousands of steam traps tested individually in just 3 seconds! ARI-Armaturen will present “CONA®-control” – a new, calorimetric test system for remote monitoring of steam traps – at ACHEMA 2006 (Hall 8.0 Stand U25-U29). The system is ASI wired and can be connected in a Profibus/Fieldbus/Ethernet network. This test technology has been submitted by the manufacturer for patent and offers a host of benefits to customers. Amongst other things, users are now able to selectively exchange single, defective steam traps, even in large plants, without wasting valuable time because they are individually and continuously monitored. By connecting "CONA®control” to Profibus or another higher-level bus system, they can test thousands of steam traps in a matter of seconds – unnecessary energy losses due to undetected defects are efficiently eliminated! Steam traps are required to operate continuously. Early detection of malfunctions is consequently very important to prevent significant energy losses from the plant. Unlike conventional systems, CONA®-control does not measure the conductivity of the condensate but the temperature. Whereas in the past sensors were often unable to work efficiently owing to deposits (e.g. magnetite), the new – calorimetric – testing technique guarantees perfect functioning every time. This unique technology has now been submitted for patent by ARI. If a variable (!) temperature range pre-setted by the user is exceeded, the system reports a constant leakage of steam, while underrange is interpreted as a clogged steam trap. What is the secret behind this technology? - If a constant leakage of steam occurs, the condensate inside the steam trap is forced downwards in a special test chamber. The sensors are consequently immersed in hot steam and an error is reported due to the increased temperature difference. If a steam trap is clogged, the condensate resides in it for longer and eventually cools down. The sensor indicates a malfunction if the temperature falls below i.E.100°C (free adjustable setting). CONA®-control comprises a sensor, which is flanged either directly in the steam trap or as a separate sensor chamber (essential for certain trap types), and one amplifier with local display per sensor. The complete system is wired over an ASI bus. An ASI bus pc board in the amplifier allows data exchange via a bus coupler into all popular bus systems, such as Profibus, Fieldbus, Ethernet, etc. The sensors with a measuring amplifier can also be used without a bus system as a local display only, in other words as a visualisation function. One of the main advantages of this function test technology is that malfunction is reported promptly because the steam traps are monitored continuously and individually. Energy losses from the plant are avoided. The fact that the system is wired over an ASI bus additionally increases the malfunction reporting speed. Since each steam trap is monitored individually and continuously, defective traps can be exchanged easily and selectively without delay, even in large plants. Moreover, if a steam trap is reported as defective, then it really is defective. Sensor malfunctions due to magnetite deposits are a thing of the past. The new ARI system does not only report leakages. It also instantly detects clogged steam traps that are no longer able to drain off condensate and allows them to be exchanged as soon as the fault occurs. Water hammers, which in the worst case can bring the entire plant to a standstill, are reliably prevented. In view of the steadily rising costs for energy consumption coupled with mounting economic pressures, technologies to optimise energy utilisation are in considerable demand. The new “CONA®-control” test system harmonises perfectly with the complete range of steam traps up to PN 630, which will naturally also be exhibited at ACHEMA: CONA® S, the ball float steam trap for immediate discharge with no loss of temperature. CONA® B, the bimetallic steam trap for selective condensate sub-cooling and minimal post-evaporation. CONA® TD, the thermodynamic steam trap that is compact, practical and impervious to weather. CONA® M, the thermostatic steam trap for rapid discharge, reduced post-evaporation and condensate sub-cooling. CODI®, the manifold for collecting and distributing condensate, steam and fluids.

Open the catalog to page 1

ARI will additionally showcase ARImetec-S, the new multi-function tester for steam plants. This ultrasonic measuring instrument with integrated temperature measurement (optional, up to 800°C) is used to measure the ultrasound level of steam traps or other valves and fittings (leakage) and/or a steam trap’s surface temperature (leakage). The Universal Connector is a further newcomer to the ARI portfolio. It allows steam traps to be exchanged quickly and easily – without interrupting plant operation! Ilustration CONA®-control – the new, calorimetric test system for monitoring steam traps....

Open the catalog to page 2All ARI-Armaturen catalogs and technical brochures

-

CONA® Compact discharge

7 Pages

-

STEVI-POS

2 Pages

-

ZEDOX HEXO

5 Pages

-

ARI-STEVI Smart 425/426

16 Pages

-

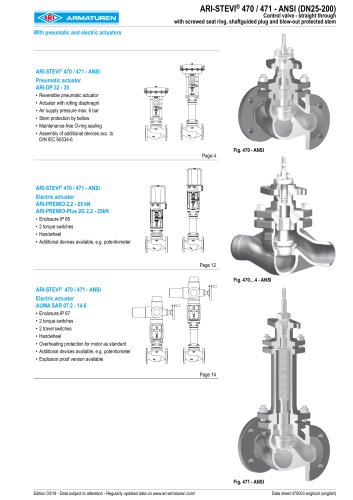

ARI-STEVI Pro 470/471 ANSI

28 Pages

-

FABA - Bellows sealed valve

5 Pages

-

SAFE - Variable & safe

8 Pages

-

CONA All-in-One

2 Pages

-

PREMIO Plus 2G

2 Pages

-

STOBU

2 Pages

-

FABA

5 Pages

-

STEVI - Control valves

9 Pages

-

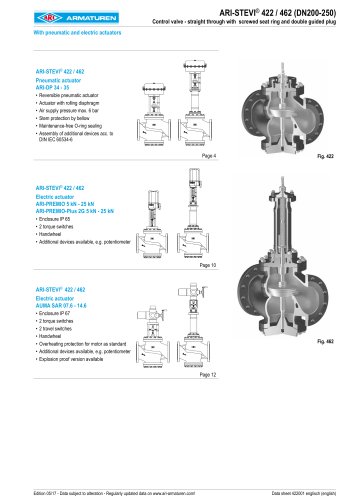

ARI-STEVI Pro 422/462

20 Pages

-

ARI-STEVI Pro 470/471

28 Pages

-

SAFE Flyer

2 Pages

-

CONA - Compact discharge

7 Pages

-

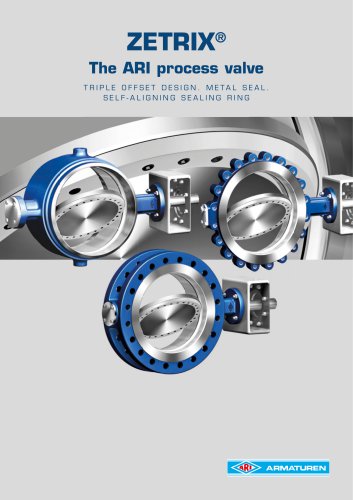

ZETRIX - ARI process valve

8 Pages

-

CONLIFT

2 Pages

-

FABA - the new generation

5 Pages

-

ARI systems

2 Pages

-

SHR

2 Pages

-

PREMIO ® -Plus 2G

2 Pages

-

CONA®B

2 Pages

-

mechanical condensate pump

2 Pages

-

Back pressure safety valves

12 Pages

-

ARI SAFE SN ANSI

16 Pages

-

ARI SAFE

36 Pages

-

ARI tempotal

20 Pages

-

ARI PRESO

4 Pages

-

472 series

24 Pages

-

Your "One-Stop-Shop" in ANSI

8 Pages

-

e.g. ARImetec-DX

4 Pages

Archived catalogs

-

e.g. SAFE / SAFE-P

2 Pages

-

Application engineering

2 Pages

-

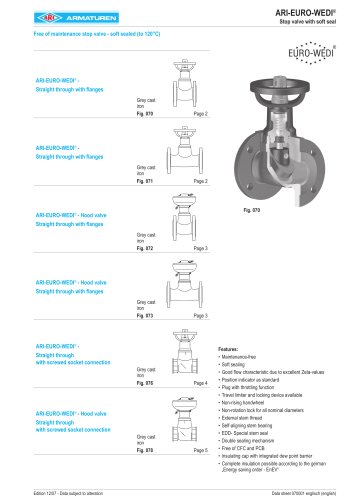

EURO-WEDI

2 Pages

-

PREMIO Plus

2 Pages

-

TEMPTROL

2 Pages

-

STEVI AS

6 Pages

-

ARI-CODI S

8 Pages

-

ARI-CONA B

20 Pages

-

ARI-Strainer

6 Pages

-

ARI-FABA Long Life

16 Pages

-

ARI-Check valve

12 Pages

-

Pressure Reducing Valve

6 Pages

-

Metallic sealing

4 Pages