Catalog excerpts

Proportional Directional Control Valves Compact design with integrated electronics High reliability Simple replacement of the exciting coils including electronics without opening the hydraulic circuits Continuous flow control in both directions Installation dimensions to DIN 24 340 / ISO 4401 / CETOP RP121-H Functional Description The proportional directional valve consists of a cast-iron housing, a special control spool, two centering springs with supporting washers and one or two proportional solenoids. A control box, which comprises one or two electronic control cards, depending on the number of the controlled solenoids, can be mounted onto either solenoid. With the model with two solenoids, the solenoid mounted apposite the control box is connected with the box by means of a EN connector, a two-cored cable and a bushing. The connection of the control box with the supply source and with the control signal is realized by means of a 4-pin connector, type M12 x 1. The solenoid coils, including the o control box, can be turned in the range of ± 90 . The electric control unit supplies the solenoid with current, which varies with the control signal. The solenoid shifts the control spool to the required position, proportional to the control current. The electronic control unit provides the following adjustment possibilities: Offset, Gain, rise and drop-out time of the ramp generator, frequency (2 frequencies) and amplitude of the dither signal generator. The correct function of the control unit is signaled by LED-diodes. Stabilized voltage +10V (+5V for 12V voltage) is also available for the user. By the use of this voltage, a voltage control signal can be made by means of a potentiometer ³ 1 kW. The electronic control card enables voltage or current control to be used, according to the positions of the switches SW1 to SW3 (see table on page 6). The basic surface treatment of the valve housing is phosphate coated, the operating solenoids are zinc coated.

Open the catalog to page 1

Ordering Code Proportional Directional Control Nominal size without designation without designation without electronics (supplied with counterpart) Nominal supply voltage Nominal flow rate at Ap = 10 bar (145 PSI) * Model for cylinders with asymmetric piston rod, piston area ratio 1:2

Open the catalog to page 2

Technical Data Valve size Maximum operating pressure at ports P, A, B Maximum operating pressure at port T Hydraulic fluid Hydraulic oils of power classes (HL, HLP) to DIN 51524 Fluid temperature range NBR / Viton Viscosity range Maximum degree of fluid contamination Nominal flow rate Qn at Dp = 145 PSI (10 bar) n = 32 mm2×s-1(n = 156 SUS ) Mounting position unrestricted, preferably horizontal Technical Data of the Proportional Solenoid V o Mean resistance value at 20 C (68 °F) Limit current Nominal supply voltage Technical Data of the Electronics Nominal supply voltage Ucc Supply voltage...

Open the catalog to page 3

Flow Characteristic with Integrated Electronics Measured at Dp = 10 bar (145 PSI), n = 32 mm2/s (156 SUS) Flow Characteristic without Integrated Electronics 2 Values in parenthesis are valid for the supply voltage 12 V. The coil current which initializes the flow through the proportional directional valve can differ due to the production tolerances about in a range of ± 6% of the limit current. Transient Characteristic 5% t4 Time t [ms] the control signal course of the integrated electronics Steady spool position ss [%] The values in table have only an informative character. The times of...

Open the catalog to page 4

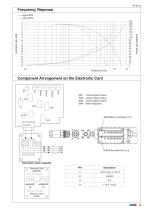

Frequency Reponse

Open the catalog to page 5

Table of the Switch Configuration for the Control Signal Choices Designation of the basic manufacture setting. The ramp functions are adjusted on their minimum values, the dither is set to the optimal value with respect to hysteresis. Offset and Gain are adjusted according to the characteristic on page 3 and 4. The manufacturer does not recommend these adjusted values to be changed. * Input signal level for the 12 V electronic unit. Block Diagram STABILIZED VOLTAGE CONTROL CONNECTION SOLENOID COIL

Open the catalog to page 6

Valve PRM6-102 (with One Solenoid)_ 1.1 Control with external voltage source 0 ... 10 V (0 ... 5 V) or with external potentiometer R >1 kQ The control signal must have the same ground potential as the supply source. Master card for solenoid a (b) oooo oooo Wire colours (connection connector - electronics): amplitude - optimum Offset, Gain: according to the characteristics on page 3, 4

Open the catalog to page 7

Valve PRM6-102 (with One Solenoid)_ 2 Other control possibilities 2.1 Control with external source 0 ... 5 V The control signal must have the same ground potential as the supply source. Master card for solenoid a (b) For the factory setting modification for this case of application, the following steps are required: 1. Unscrew the electronics cover 2. Carefully remove the Master card 3. Flip the switch SW3 in position shown in the picture 4. Put in the Master card and fix the electronics cover 5. Connect the voltage +24 V from an external supply source to terminals 1 and 3 of the connector...

Open the catalog to page 8

Valve PRM6-102 (with One Solenoid) 2.2 Control with external source 0 ... 20 mA The control signal must have the same ground potential as the supply source. Master card for solenoid a (b) For the factory setting modification for this case of application, the following steps are required: 1. Unscrew the electronics cover 2. Carefully remove the Master card 3. Flip the switch SW1 and SW3 in position shown in the picture 4. Put in the Master card and fix the electronics cover 5. Connect the voltage +24 V (+12 V) from an external supply source to terminals 1 and 3 of the connector 6. Bring the...

Open the catalog to page 9

Valve PRM6-102 (with One Solenoid)_ 2.3 Control with external source 4 ... 20 mA The control signal must have the same ground potential as the supply source. Master card for solenoid a (b) For the factory setting modification for this case of application, the following steps are required: 1. Unscrew the electronics cover 2. Carefully remove the Master card 3. Flip the switch SW1, SW2 and SW3 in position shown in the picture 4. Put in the Master card and fix the electronics cover 5. Connect the voltage +24 V (+12 V) from an external supply source to terminals 1 and 3 of the connector 6....

Open the catalog to page 10All ARGO-HYTOS catalogs and technical brochures

-

MLS3-06

10 Pages

-

C5.3511 · C5.3516 · C5.3529

3 Pages

-

LS 040 · LS 075

6 Pages

-

ES 075

6 Pages

-

Catalogue Hydraulic Drives

65 Pages

-

Catalogue Fluid Management

69 Pages

-

Filtration Guideline

20 Pages

-

Light Line

4 Pages

-

Off-line Filtration

2 Pages

-

Catalogue Filtration

342 Pages

-

Catalogue Lightline

50 Pages

-

RC series

4 Pages

-

TS3 MTS2

6 Pages

-

TS4 MTS

6 Pages

-

ECOLINE

8 Pages

-

SR4P2-B2

4 Pages

-

SR1P2-A2

4 Pages

-

PRM7-10

10 Pages

-

PRM8-06

4 Pages

-

PRM2-04

20 Pages

-

PRM7-06

10 Pages

-

PRM2-06

20 Pages

-

PRM7-04

10 Pages

-

Coils

18 Pages

-

Datasheet RPEL1-06

6 Pages

-

Datasheet RPH2-06

4 Pages

-

Datasheet RPR3-04

4 Pages

Archived catalogs

-

MDA Highlights 2015

24 Pages

-

Solutions for clean Oil

6 Pages

-

Brochure for Endusers

2 Pages

-

Agritechnica Highlights 2015

32 Pages

-

Brochure Wind Energy

2 Pages

-

EXAPOR MAX 2

3 Pages

-

Guidelines

21 Pages

-

Product summary

16 Pages

-

ARGO-HYTOS program summary

16 Pages