Catalog excerpts

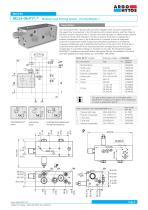

Modular Load Sensing System Size 06 (D03) Qmax 100 l/min (26.4 GPM) pmax 250 bar (4600 PSI) Possible Applications Priority module 1 Priority module 2 Base module Section module RPEK distributors Section module RPEK Technical Features ›› ›› ›› ›› ›› ›› ›› ›› ›› ›› ›› ›› Modular manifold system for the work hydraulics in mobile machines Designed to the complex and variable demands of mobile hydraulics needs Modular concept based on existing modular and screw-in valve technology by ARGO-HYTOS Standard modules easily adaptable for specific applications Various modules allow the integration of various options into the standard modules Modules on manufacturer’s stock shorten machine development time at the producers Modularity offers short delivery time and flexibility in the field during validation stage Load sensing control of pressure source from each working section Each working section is pressure compensated for constant performance Flexible modules including inlet block, section blocks, priority function (e.g. steering) or other optional blocks Inlet section suitable for both LS pumps and fixed displacement pumps Basic modular valves interface with sub plate mounting pattern acc. to ISO 4401, DIN 24340 (CETOP 03) Functional Description The MLS kit is intended for hydraulic circuits with several hydraulic actuators being used at the same time with different loads. These kit systems provide two basic functions . First, they provide a constant pressure drop on operating valves of each section. A pressure compensator in each section ensures that the flow is independent of the load on the section. The second function is energy saving. The logic valves in the MLS choose the highest pressure needed in the system for a given section. This pressure signal is connected into the LS channel, which is used to control the pressure source. The pressure source can either be a regulated pump with LS control or a fixed displacement pump. If a fixed displacement pump is used, the LS signal controls the pressure compensator (pos 6). The LS signal drives the pressure source to the required value in real-time. Therefore, no energy is wasted on the relief valve, which must be set to the highest expected pressure. MLS modular kits consist of the following modules Priority module P1 The module with a priority valve, pressure compensator and one integrated main consumer establishes a supply to consumers in the first priority. Priority module P2 The module for the second priority consumer function is attached to the „Priority module 1“. Base module B The inlet module with pressure compensator realizes a LS pressure depending on the need of the consumers and has 2 consumer sections. The consumer ports are flangable to optional modules A and B. The LS signal of the base module can be electrically unloaded. Section module S The section module is used in cases where additional consumer functions are needed. It is flangable to the base module as well, the consumer port side is flangable to optional modules A and B. Section module SRPEK The SRPEK module is designed to connect two or more RPEK1-03 valves via two pressure compensators. Optional modules A and B These modules enable additional functions at the consumer side, such as load holding, electrical cylinder unload etc.

Open the catalog to page 1

Design Recommendations Relief and unloading of the LS line: In the MLS system only one relief valve on the main P line is implemented, therefore the used LS pump must have its own relief of the LS line. The LS line pressure in the Base module of the system can be released to the tank by an electrical unloading valve. Technical specifications of the module: The specified values for operating pressure, flow rate and temperatures in the technical documentation are consistent with the values for the recommended valves in the ARGO-HYTOS program. Operation at low temperatures: Minimum storage...

Open the catalog to page 2

Illustratice Picture *Use CETOP valve with just one solenoid on side A where block OA is used www.argo-hytos.com Subject to change · MLS3-06_0025_3en_05/20

Open the catalog to page 3

Modular valves mounting surface Studrods Studrods / Bolts MLS3-06 Optional module Bolts, nuts and washers are not delivered. www.argo-hytos.com Subject to change ■ MLS3-06_0025_3en_05/2019

Open the catalog to page 4

MLS3-06-B*/* Modular Load Sensing System - Basic Module The inlet base module with pressure compensator realizes a LS pressure depending on the consumer demand. This ensures that always the highest pressure required will be provided by the LS pump. If there are no consumers active, there will be an unpressurized flow corresponding to the pressure compensator. It is possible to flange-on priority modules on one side and sectional modules from the other side. The inlet base module MLS3-06-B* includes two consumer sections for the installation of control valves with subplate mounting interface...

Open the catalog to page 5

MLS3-06-P1*/* Modular Load Sensing System - Priority Module 1 The inlet module with a priority valve and one integrated main consumer implements the supply flow to consumers in the first priority and in second priority, and from there to the other sections. Typical priority 1 functions are steering (open- or closed-center), priority 2 functions include work hydraulics. The flow in priority consumers is supplied by a pressure compensator valve. In the third priority it is possible to use the integrated consumer in proportional mode. Supply and overpressure protection is achieved by a...

Open the catalog to page 6

MLS3-06MLS3-06-P2*/* Modular Load Sensing System - Priority Module 2 Description The Priority module 2 and Section block „S" implement an on/off or proportional consumer supply depending on the valve installation. The Priority module 2 extends the Priority module 1 while the Section block „S" extends the Base module. They are used in situations when additional consumers need to be operated. Sections are always compensated with 2-way pressure compensators. The LS signal is reported via check valves. Note: The modules are not interchangeable. ‘[Tl/ATc-iTi-TObb NGoe\ ____ www.argo-hytos.com...

Open the catalog to page 7All ARGO-HYTOS catalogs and technical brochures

-

C5.3511 · C5.3516 · C5.3529

3 Pages

-

LS 040 · LS 075

6 Pages

-

ES 075

6 Pages

-

Catalogue Hydraulic Drives

65 Pages

-

Catalogue Fluid Management

69 Pages

-

Filtration Guideline

20 Pages

-

Light Line

4 Pages

-

Off-line Filtration

2 Pages

-

Catalogue Filtration

342 Pages

-

Catalogue Lightline

50 Pages

-

RC series

4 Pages

-

TS3 MTS2

6 Pages

-

TS4 MTS

6 Pages

-

ECOLINE

8 Pages

-

SR4P2-B2

4 Pages

-

SR1P2-A2

4 Pages

-

PRM7-10

10 Pages

-

PRM8-06

4 Pages

-

PRM2-04

20 Pages

-

PRM6-10

20 Pages

-

PRM7-06

10 Pages

-

PRM2-06

20 Pages

-

PRM7-04

10 Pages

-

Coils

18 Pages

-

Datasheet RPEL1-06

6 Pages

-

Datasheet RPH2-06

4 Pages

-

Datasheet RPR3-04

4 Pages

Archived catalogs

-

MDA Highlights 2015

24 Pages

-

Solutions for clean Oil

6 Pages

-

Brochure for Endusers

2 Pages

-

Agritechnica Highlights 2015

32 Pages

-

Brochure Wind Energy

2 Pages

-

EXAPOR MAX 2

3 Pages

-

Guidelines

21 Pages

-

Product summary

16 Pages

-

ARGO-HYTOS program summary

16 Pages