Catalog excerpts

Gear Pump

Open the catalog to page 1

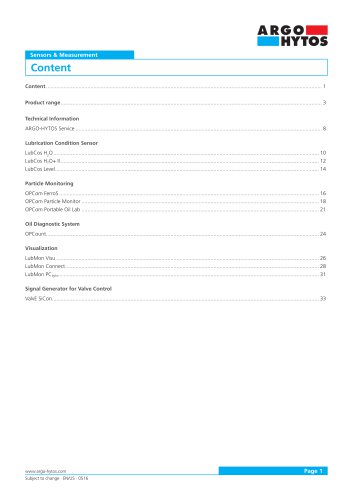

Product range Suction filters Clogging indicators Ventilating filters Return filters Pressure filters Return-suction filters High pressure filters Return-suction filters Description ARGO-HYTOS produces sophis icated filter solutions together t with hydraulic and lubrication systems. The range of solutions we have implemented extends from fixed-position industrial plants to mobile applications. As well as customized developments, exactly adjusted to the individual requirements of the customer, ARGO-HYTOS offers a com rehensive range of innovative standard solutions for a wide p variety of...

Open the catalog to page 3

Product range Fluid and Motion Control Customized solutions Gear pumps Control solutions www.argo-hytos.com Subject to change · 02/2015

Open the catalog to page 4

Product range Fluid and Motion Control Directional and proportional valves Modular valves Sandwich valves Screw-in cartridge valves Slip-in cartridge valves Load motion cartridges Explosion proof valves Hydraulic power packs Description ARGO-HYTOS’ expertise in control technology is the fruit of more than 65 years‘ experience. We focus here on a wide range of valves,power units and integrated manifolds featuring all commonly used design features and functions, together with proportional valves and the associated control electronics: ›› Directly operated directional valves in CETOP 02 to...

Open the catalog to page 5

Product range Fluid Management Off-line filter Off-line filter Off-line filter unit Off-line filter unit Dewatering system Dewatering system Description As well as reducing maintenance and servicing costs, effective fluid management is also a key factor in boosting the reliability, productivity and cost-effectiveness of the operation. ARGO-HYTOS supplies application-oriented products for manual and automatic cleaning of hydraulic fluids: ›› Off-line filters ›› Off-line filter units ›› Filter cooling systems ›› Oil service units ›› Dewatering systems

Open the catalog to page 6

Product range Portable particle counter Particle monitor Wear sensor Condition sensors Pressure sensor Remote interfaces / display units Valve electronics Description Systems that provide reliable assessment of the conditionof hydraulic fluids are the key feature of continuous fluid monitoring. Sensors and measurement technology from ARGO-HYTOS p recisely target this range of tasks. Our fluid monitoring p roducts comprise equipment and system solutions to enable online monitoring during continuous operation as well as analysis of bottled samples under laboratory conditions. ››...

Open the catalog to page 7

General Information Experience, innovation, continuous optimization by means of mathematical analysis and testing - these are important prerequisites for the development and production of advanced products with wide application potential in both stationary and mobile applications. Our product portfolio includes valves for hydraulic circuit control, manifolds and HICs, as well as complete hydraulic drives. We manufacture standard catalog products as well as tailor-made products for specific applications. We collaborate in the development and realization of our customers' technical projects....

Open the catalog to page 8

Overview of parameters of the basic series (This table provides an overview of comparative performance. Precise values are stated in the catalogue of individual pumps). 3. Joining of pumps into groups Multiple designs Gear pumps are suitable for multiple setups, whereby the drive shaft for the 1st pump is extended to a second and even a 3rd pump. A coupling is fitted between each pair of pumps. In most cases each pump is isolated from its neighbor, i.e. the suction ports are separate from one another. A common suction port is also possible as an option. Caution: Basically, the...

Open the catalog to page 9

5. Coupling The construction design of the drive shafts ends corresponds to the transferred torque. The pump shaft must not be loaded by an additional external force in either the axial or radial direction. This is why it is recommended to use a flexible coupling. The maximum deviation of mutual alignment of the motor shaft and the centering pump diameter is 0.04 mm when using a coupling without a flexible element, and 0.1 mm when using a coupling with a flexible element, which partially balances alignment deviations. The perpendicularity of the seating front flange to the motor shaft is...

Open the catalog to page 10

Flow Internal diameter pipes [l.min-1] [In] [mm] Basic technical parameters 6. Mounting, dismounting and operating instructions The gear pump can be mounted in any position. Make sure that the gear pump is clean and free of visible damage prior to mounting it. Protective covers prevent ingress of dirt into the inlet and outlet ports. These covers must not be removed until the pump is connected to the hydraulic circuit. In order to make sure that proper mounting is possible, ascertain that all flange faces are clean and free of damage. The pump and the bellhousing are positioned with the...

Open the catalog to page 11

Gear Pump - Lightline Version Technical Features www.argo-hytos.com Subject to change ■ GPOL_8013_1a_03/2015

Open the catalog to page 12

Direction of rotation, reversible design Determine direction of rotation by looking at the drive shaft. The pump can be used only in the specified direction of rotation. CLOCKWISE “R“ Ordering Code Shaft seal No designation standard 004 without shaft seal Direction of rotation Counter clockwise Clockwise Inlet / Outlet port Flange side port BSP G1/4 BSP G3/8 M10x1 Flange design Flange with two bolts M6 - centre ring Ø 22 mm (0,87 in) Flange with two bolts M5 - centre ring Ø 22 mm (0,87 in) screw pitch 30x32 mm (1,18x1,26 in) Ports orientation Shaft Type Ports orientation Flange design in...

Open the catalog to page 13

Shaft design in millimeters (inches) Ports design in millimeters (inches) Inlet / outlet Displacement [cm3(in3)] Pump design in millimeters (inches)

Open the catalog to page 14

Pump design in millimeters (inches) www.argo-hytos.com Subject to change • GPOL_8013_1a_03/2015 Page 15

Open the catalog to page 15All ARGO-HYTOS catalogs and technical brochures

-

MLS3-06

10 Pages

-

C5.3511 · C5.3516 · C5.3529

3 Pages

-

LS 040 · LS 075

6 Pages

-

ES 075

6 Pages

-

Catalogue Fluid Management

69 Pages

-

Filtration Guideline

20 Pages

-

Light Line

4 Pages

-

Off-line Filtration

2 Pages

-

Catalogue Filtration

342 Pages

-

Catalogue Lightline

50 Pages

-

RC series

4 Pages

-

TS3 MTS2

6 Pages

-

TS4 MTS

6 Pages

-

ECOLINE

8 Pages

-

SR4P2-B2

4 Pages

-

SR1P2-A2

4 Pages

-

PRM7-10

10 Pages

-

PRM8-06

4 Pages

-

PRM2-04

20 Pages

-

PRM6-10

20 Pages

-

PRM7-06

10 Pages

-

PRM2-06

20 Pages

-

PRM7-04

10 Pages

-

Coils

18 Pages

-

Datasheet RPEL1-06

6 Pages

-

Datasheet RPH2-06

4 Pages

-

Datasheet RPR3-04

4 Pages

Archived catalogs

-

MDA Highlights 2015

24 Pages

-

Solutions for clean Oil

6 Pages

-

Brochure for Endusers

2 Pages

-

Agritechnica Highlights 2015

32 Pages

-

Brochure Wind Energy

2 Pages

-

EXAPOR MAX 2

3 Pages

-

Guidelines

21 Pages

-

Product summary

16 Pages

-

ARGO-HYTOS program summary

16 Pages